Markings provide important information about the contents of a packaging, freight container, or transport vehicle and help warn of hazards posed by that material during transport. The markings give additional information, not provided by labels or placards, about the hazardous material in a package or vehicle.

Labels are printed on or affixed to packages containing hazardous materials. Color- and symbol-coded, labels provide easy and immediate warning of the hazardous materials inside a package. The Hazardous Materials Regulations (HMR) have specific requirements for design, use, placement, prohibitions, and exceptions for labels.

Hazardous materials placards correspond closely with the shape, color, and design of hazardous materials labels. However, placards are much larger than labels. Placards alert people to potential dangers associated with particular hazardous materials contained in motor vehicles, rail cars, freight containers, cargo tanks, and portable tanks.

Key definitions

Specific definitions for terms associated with markings, placards, and labels clarify their meaning.

Definitions for markings terminology

Bulk packagings: Other than vessels or barges, and including transport vehicles or freight containers, are bulk packagings in which hazardous materials are loaded with no intermediate form of containment and that have:

- A maximum capacity greater than 119 gallons (450 L) as a receptacle for a liquid;

- A maximum net mass greater than 882 pounds (400 kg) and a maximum capacity greater than 119 gallons (450 L), as a receptacle for a solid; or

- A water capacity greater than 1,000 pounds (454 kg), as a receptacle for a gas.

A large packaging in which hazardous materials are loaded with an intermediate form of containment, such as one or more articles or inner packagings, is also a bulk packaging.

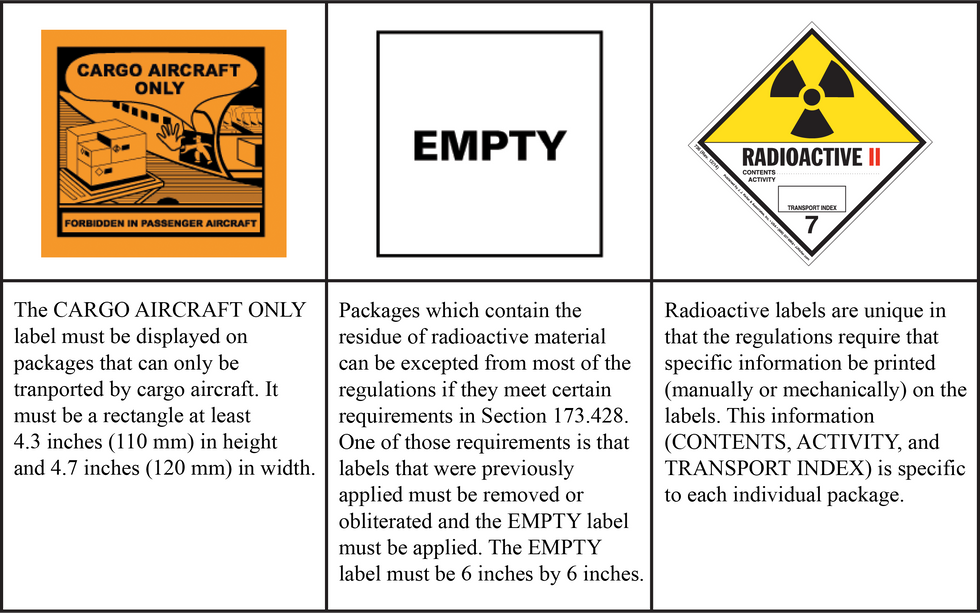

Cargo aircraft only: This aircraft is used to transport cargo and is not engaged in carrying passengers. The terms “cargo aircraft only,” “cargo-only aircraft,” and “cargo aircraft” have the same meaning.

Limited quantity: When specified as such in a section applicable to a particular material, it means the maximum amount of a hazardous material for which there is a specific labeling or packaging exception.

Marking: This consists of a descriptive name, identification number, instructions, cautions, weight, specifications, or United Nations (UN) marks, or combinations thereof, required by the Hazardous Materials Regulations (HMR) on outer packagings of hazardous materials.

Non-bulk packagings: These packagings have:

- A maximum capacity of 119 gallons (450 L) or less as a receptacle for a liquid,

- A maximum net mass of 882 pounds (400 kg) or less and a maximum capacity of 119 gallons (450 L) or less as a receptacle for a solid,

- A water capacity of 1,000 pounds (454 kg) or less as a receptacle for a gas, or

- A maximum net mass of 882 pounds (400 kg) or less for a bag or a box conforming to the specification packaging requirements in Subpart L of Part 178.

Technical name: This is a recognized chemical name or microbiological name currently used in scientific and technical handbooks, journals, and texts. Generic descriptions are authorized for use as technical names provided they readily identify the general chemical group or microbiological group. Examples of acceptable generic chemical descriptions are organic phosphate compounds, petroleum aliphatic hydrocarbons, and tertiary amines. For proficiency testing only, generic microbiological descriptions such as bacteria, mycobacteria, fungus, and viral samples may be used. Except for names that appear in Subpart B of Part 172 of this subchapter, trade names may not be used as technical names.

Definitions associated with placards

Freight container: A reusable container having a volume of 64 cubic feet or more, designed and constructed to permit being lifted with its contents intact and intended primarily for containment of packages (in unit form) during transportation.

Rail car: A car designed to carry freight or non-passenger personnel by rail, and includes a box car, flat car, gondola car, hopper car, tank car, and occupied caboose.

Residue: The hazardous material remaining in a packaging, including a tank car, after its contents have been unloaded to the maximum extent practicable and before the packaging is either refilled or cleaned of hazardous material and purged to remove any hazardous vapors.

Subsidiary hazard: The hazard of a material other than the primary hazard.

Transport vehicle: A cargo-carrying vehicle such as an automobile, van, tractor, truck, semitrailer, tank car, or rail car used for transportation of cargo by any mode. Each cargo-carrying body (trailer, rail car, etc.) is a separate transport vehicle.

Unit load device: Any type of freight container, aircraft container, aircraft pallet with a net, or aircraft pallet with a net over an igloo.

Definitions of terms associated with labels

Dewar flask: An insulating storage vessel that greatly lengthens the time during which its contents remain hotter or cooler than the flask’s surroundings. The vacuum flask consists of two flasks, placed one within the other and joined at the neck. The gap between the two flasks is partially evacuated of air, creating a near-vacuum that significantly reduces heat transfer by conduction or convection.

Limited quantity: When specified as such in a section applicable to a particular material, it means the maximum amount of a hazardous material for which there is a specific labeling or packaging exception.

Overpack: An enclosure used by a single consignor to provide protection or convenience in handling a package or to consolidate two or more packages. Overpack does not include a transport vehicle, freight container, or aircraft unit load device.

Examples of overpacks are one or more packages:

- Placed or stacked onto a load board such as a pallet and secured by strapping, shrink wrapping, stretch wrapping, or other suitable means; or

- Placed in a protective outer packaging such as a box or crate.

Primary label: A hazard warning label that corresponds with the primary hazard of the material.

Subsidiary label: A hazard warning label that corresponds with the subsidiary hazard of the material.

Markings

- Requirements for markings apply to both bulk and non-bulk packages.

Markings play a crucial role in conveying essential information about the contents of a packaging, freight container, or transport vehicle. They serve as warnings about the potential hazards posed by the materials during transportation. Beyond the warnings provided by labels or placards, markings offer additional details about the hazardous materials within a package or vehicle. This extra information can include handling instructions, specific risks, and other critical data that ensure safe and compliant transportation.

Who is responsible for markings?

- It's the shipper’s responsibility to ensure that hazardous materials are marked in accordance with the Hazardous Materials Regulations (HMR).

- Bulk and non-bulk packagings are required to have certain information displayed.

- Packagings that contain materials with certain properties or require specific handling instructions must be marked appropriately.

Marking requirements apply to non-bulk and bulk packagings transported by highway, rail, air, and vessel. Certain requirements specifically apply to transport vehicles and freight containers.

The individual who prepares non-bulk packages of hazardous material for transport is responsible for marking the package. This responsibility includes:

- Checking to ensure any relevant markings already displayed are in the correct location and in accordance with the regulations,

- Removing or obliterating any markings that are not applicable or that may reduce the effectiveness of required markings, and

- Applying any new markings in accordance with the regulations.

In most cases, the responsibility for marking bulk packagings, freight containers, and transport vehicles rests with the individual initiating the shipment. The carrier is responsible for replacing identification number markings that are lost, damaged, or destroyed during transit.

Types of markings that are prohibited

No packaging should be marked with a proper shipping name or identification number unless the packaging contains the identified material or its residue.

Specifications for markings

To withstand conditions normally encountered during transportation, all markings must be:

- Durable;

- In English;

- Printed on or affixed to the surface of a package, or on a label, tag, or sign;

- Displayed on a background of sharply contrasting color;

- Not obscured by labels or attachments; and

- Located away from any other markings, such as advertising, which could substantially reduce their effectiveness.

Manufacturer/specification packaging marking (178.503)

Most authorized packagings for hazardous materials must be marked with a United Nations (UN) packaging marking (for non-bulk packaging) or a specification packaging marking (such as DOT 406). For more information on these markings, refer to the Markings section under packaging definitions.

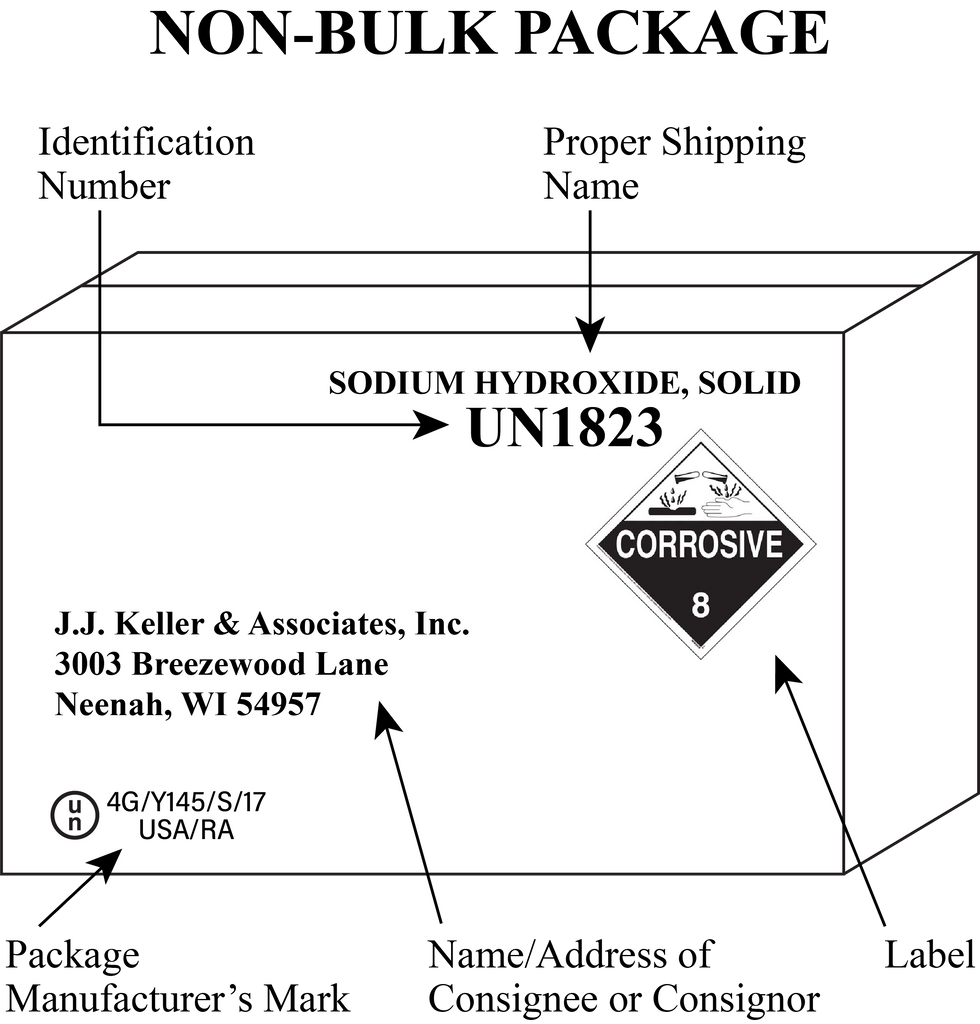

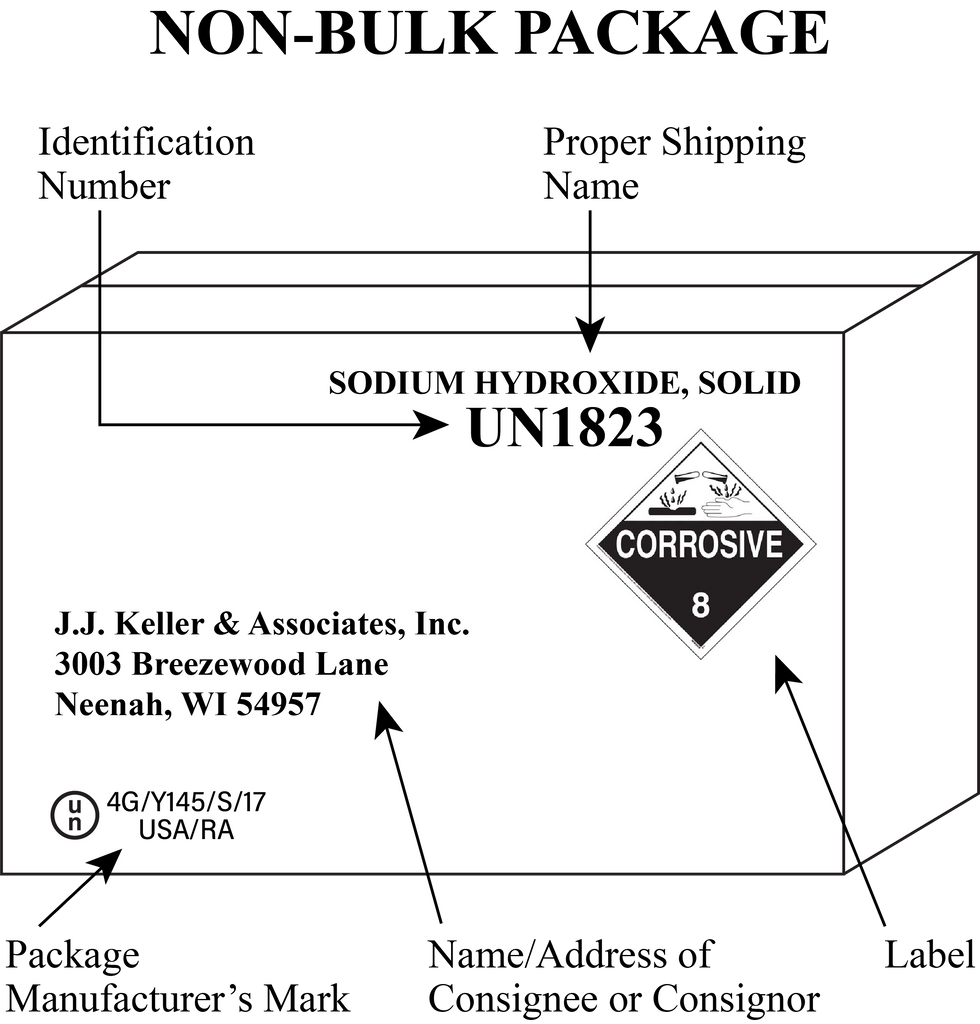

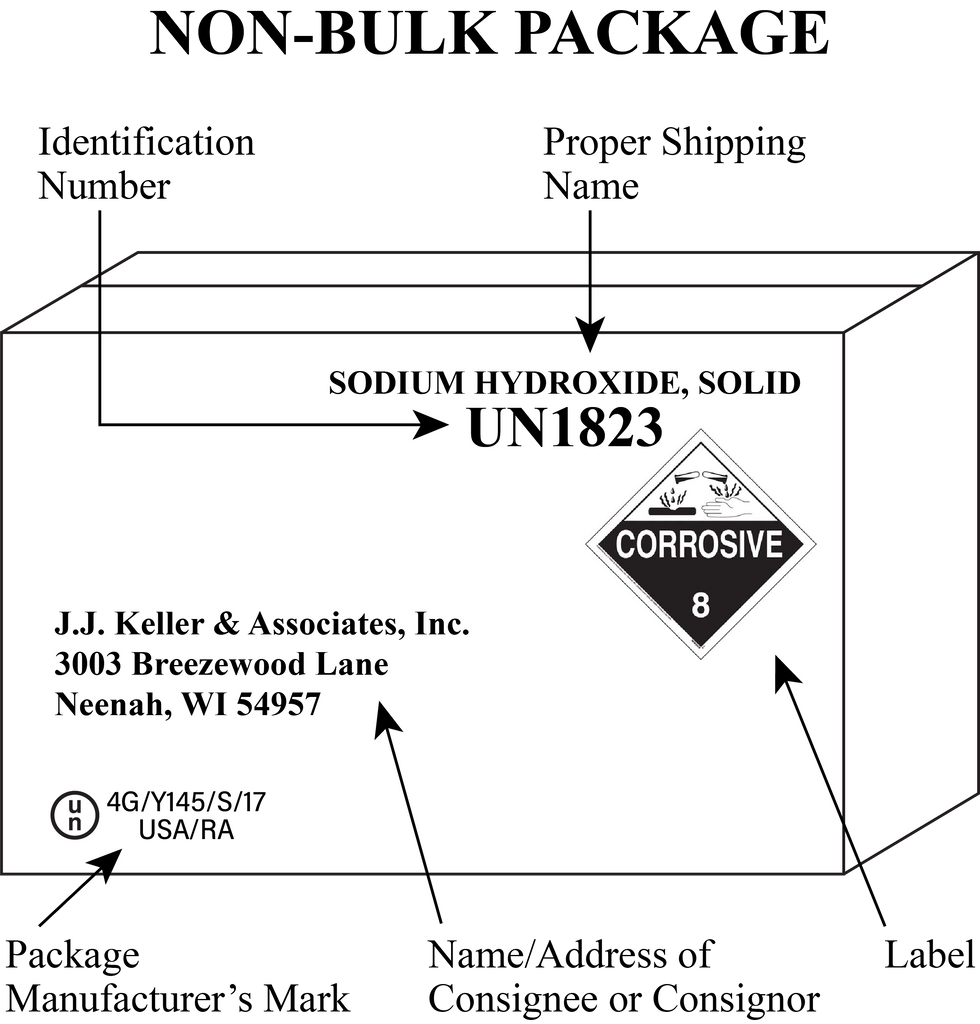

Non-bulk markings

- Specific information is required on markings for non-bulk packages.

Most non-bulk packagings must be marked with the following information:

- Description/proper shipping name;

- Technical name(s), when required;

- Identification number (preceded by “UN” or “NA” or “ID,” as appropriate);

- Consignee’s or consignor’s name and address; and

- Special permit number preceded by DOT-SP, when required.

Description/proper shipping name (172.308)

The description/proper shipping name as shown in Column (2) of the Hazardous Materials Table must be marked on the non-bulk package.

Abbreviations are usually not allowed in a proper shipping name marking. The only exception includes abbreviations appearing as part of the authorized description in Column (2) of the Hazardous Materials Table, such as “TNT” or “PCB”.

Technical names (172.301)

Any package that contains hazardous materials described by a proper shipping name preceded by the symbol “G” in Column (1) of the Hazardous Materials Table must be marked with the technical name in parentheses in association with the proper shipping name. However, a technical name should not be marked on the outer package of a Division 6.2 material.

Identification number (172.301)

The identification number shown in Column (3) of the Hazardous Materials Table, for the description/proper shipping name being used must be marked on the package. The appropriate “UN,” “NA,” or “ID” prefix must be included.

Identification numbers marked on non-bulk packagings must meet specific size requirements. The identification numbers must be at least 0.47 inches (12 mm) high. On smaller packages—8 gallons (30 L) or less, 66 pounds (30 kg) maximum, or cylinders with a water capacity of 16 gallons (60 L) or less — the identification numbers must be at least 0.24 inches (6 mm) high. For even smaller packages with a capacity of 1.32 gallons (5 L) or 11 pounds (5 kg) or less, the size of the identification numbers must be appropriate for the package size.

Name and address (172.301)

The name and address of the consignee (receiver/buyer) or consignor (shipper/seller) must be marked on the package unless:

- The package is transported by highway only and will not be transferred from one motor carrier to another; or

- The package is transported as part of a carload lot, truckload lot, or freight container load, and the entire contents of the rail car, truck, or freight container are shipped from one consignor to one consignee.

Special permit packagings (172.302)

The special permit number is required to be plainly and durably marked on the packaging if it is authorized for use under a special permit. The package should be marked “DOT-SP (followed by the special permit number).”

Hazardous substances (172.324)

Non-bulk packagings that contain a reportable quantity (RQ) of a hazardous substance must be marked with the letters “RQ” in association with the proper shipping name.

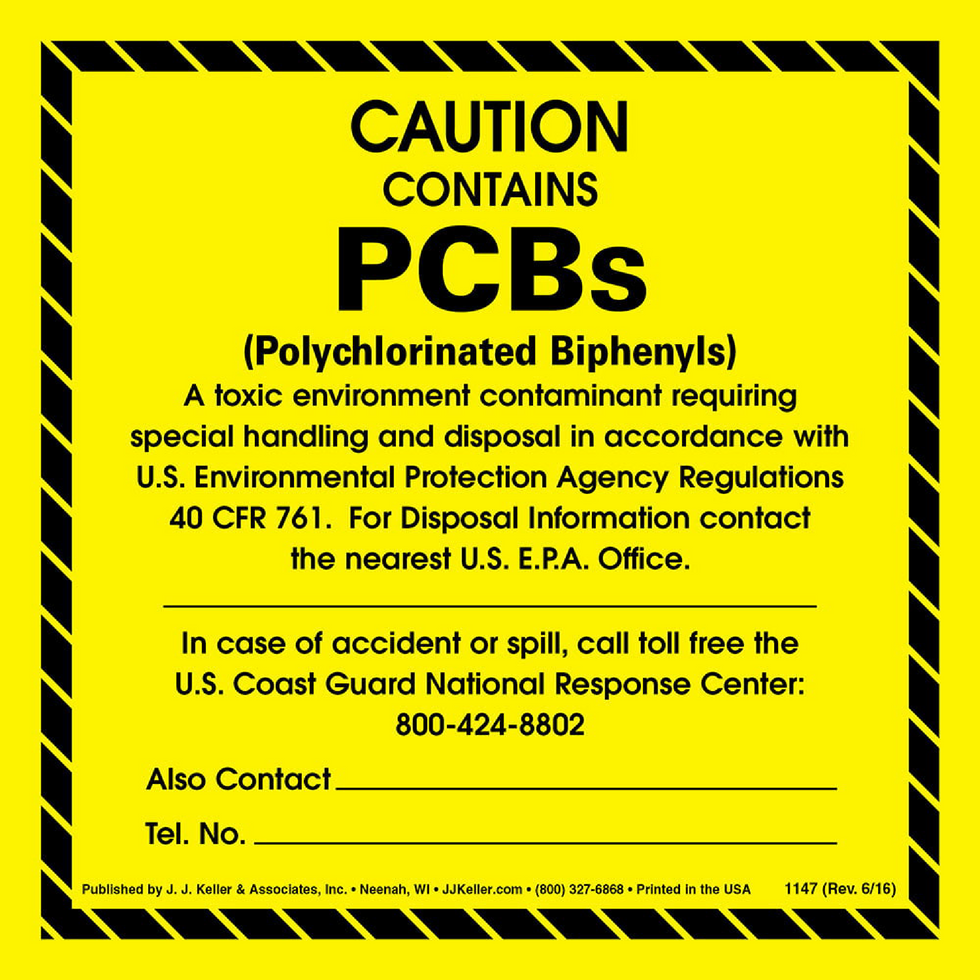

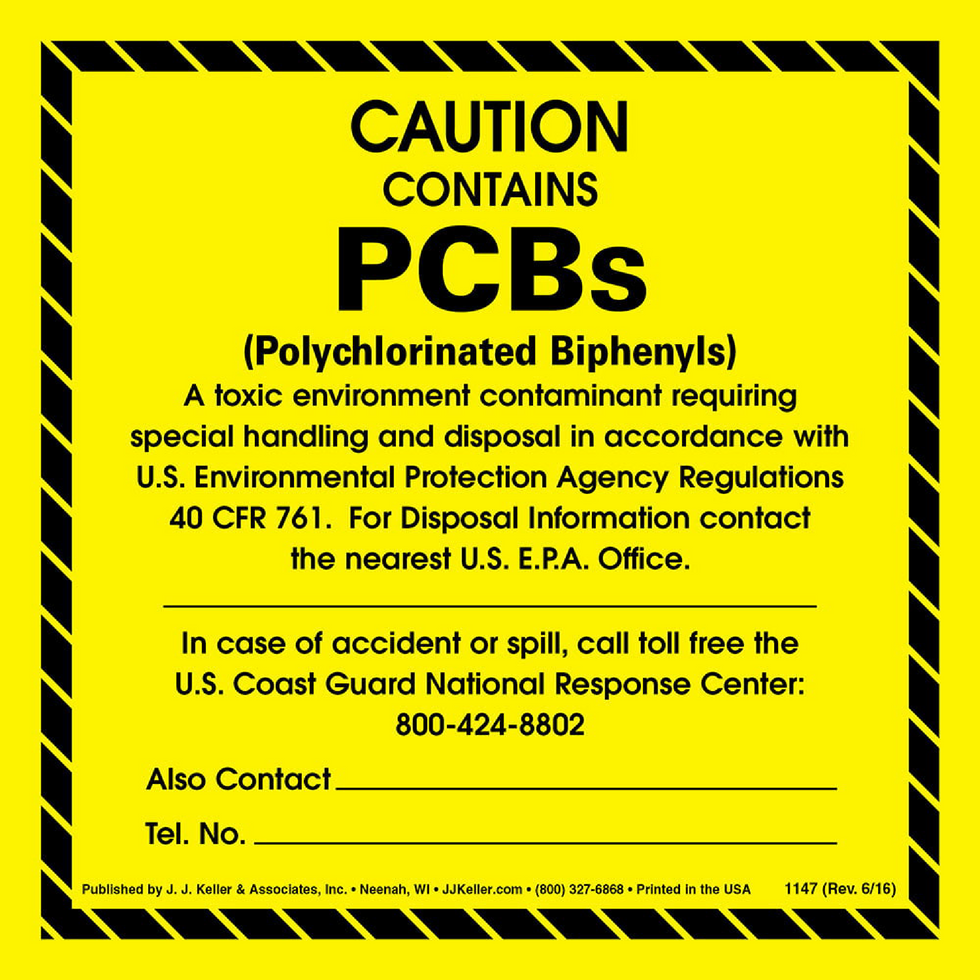

PCBs (761.40, 761.45)

Polychlorinated biphenyls (PCBs) are hazardous substances that must be transported in compliance with the Hazardous Materials Regulations (HMR) and special additional requirements of the U.S. Environmental Protection Agency (EPA).

The HMR requires the proper shipping name, identification number, and RQ to be marked on each non-bulk package.

EPA regulations require the package to be marked with the PCB mark and a minimum size of 6 x 6 inches (152.4 mm x 152.4 mm). This PCB mark may be reduced proportionately to a minimum of 2 x 2 inches (50.8 mm x 50.8 mm) to fit on PCB articles or equipment.

An even smaller rectangular PCB mark may be used on small packages. This small rectangular PCB mark may be proportionately reduced to a minimum of 0.4 x 0.8 inches (10.16 mm x 20.32 mm) to fit on PCB articles or equipment.

EPA regulations also require a vehicle to be marked on each side and each end with this marking if transporting PCB containers that contain more than 99.4 pounds (45 kg) of liquid PCBs in concentrations of 50 to 500 ppm.

Requirements for large quantities of non-bulk packages and inhalation hazards

- Non-bulk packages being transported in large quantities are subject to certain specific regulations.

- Materials poisonous by inhalation being hauled in large quantities of non-bulk packages must meet the required criteria.

Large quantities of non-bulk packages

A transport vehicle or freight container loaded with only a single hazardous material in non-bulk packages must be marked on each side and each end with the identification number specified for the material, subject to the following:

- Each package must be marked with the same proper shipping name and identification number;

- The aggregate gross weight of the hazardous material is 8,820 pounds (4,000 kg) or more;

- All of the hazardous material is loaded at one loading facility; and

- The transport vehicle or freight container contains no other material, hazardous or non-hazardous.

The above requirement does not apply to Class 1 materials, Class 7 materials, or non-bulk packagings for which identification numbers are not required, such as limited quantity materials.

Large quantities of non-bulk inhalation hazards

A transport vehicle or freight container loaded at one loading facility with 2,205 pounds (1,000 kg) or more of non-bulk packages containing a material poisonous by inhalation (in Hazard Zone A or B), having the same shipping name and identification number, must be marked with the identification number specified for the material on each side and each end.

If the transport vehicle or freight container contains more than one inhalation hazard material that meets the above identification number marking requirement, it must be marked with the identification number for only one material. That one identification number is determined by the following:

- For different materials in the same hazard zone, the identification number of the material having the greatest aggregate gross weight; or

- For different materials in both Hazard Zone A and B, the identification number for the Hazard Zone A material.

Bulk markings

- Identification numbers are mandatory for all bulk packagings of hazardous materials, though there are specific exceptions.

Unless specifically excepted, all bulk packagings of hazardous materials must be marked with the identification number(s) of the contents. These numbers, unless otherwise provided, must be marked:

- On each end and each side of a packaging having a capacity of 1,000 gallons (3,785 L) or more,

- On two opposite sides of a packaging with a capacity of less than 1,000 gallons (3,785 L), or

- On each end and each side of a tube-trailer motor vehicle.

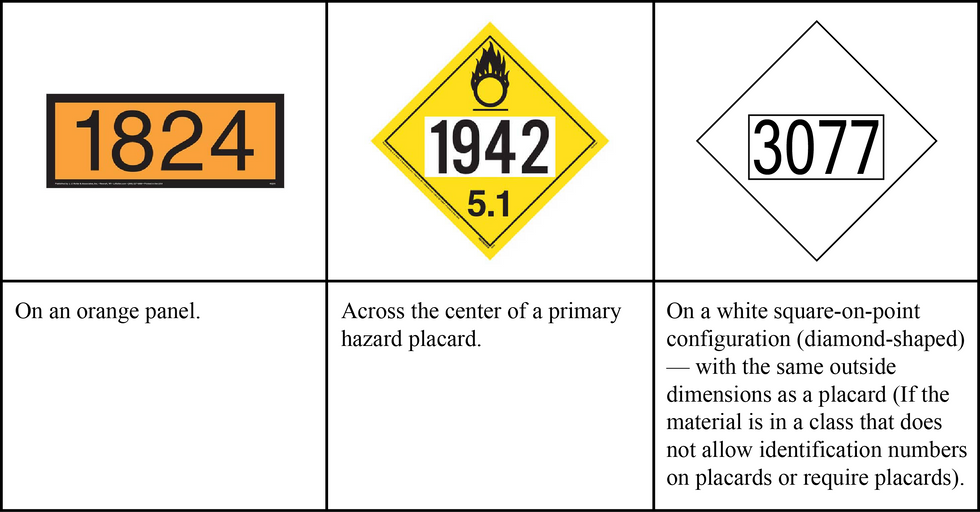

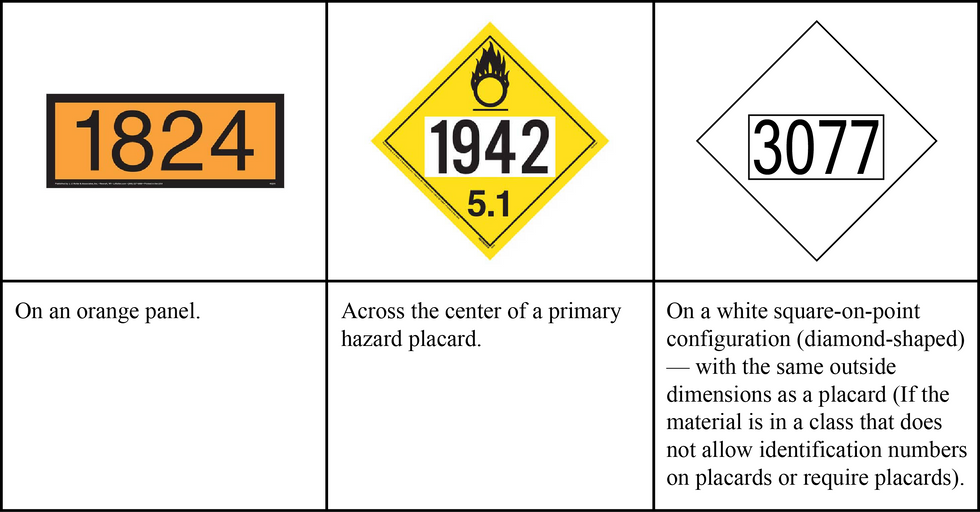

Identification number display

- Requirements for display of hazardous materials identification numbers must be observed.

- Special permit bulk packaging is subject to certain criteria.

There are three ways in which identification numbers may be displayed:

If the identification number markings on a portable tank or cargo tank are not visible, the transport vehicle or freight container used to transport the tank must also be marked with the numbers on each side and each end.

When a tank is permanently installed within an enclosed cargo body of a transport vehicle or freight container, the identification number marking need only be displayed on the sides and ends of the tank that are visible when the enclosed cargo body is opened or entered.

Identification numbers are not required on the ends of portable tanks and cargo tanks having more than one compartment if hazardous materials having different identification numbers are transported in the compartments. The identification numbers on the sides of the tank must be displayed in the same sequence as the compartments containing the materials they identify.

Special permit packaging

When a bulk packaging is labeled instead of placarded, the identification number markings may be displayed on the bulk packaging in the same manner as would be required for a non-bulk packaging.

DOT-SP (followed by the special permit number) is required to be marked on the packaging if it is authorized for use under a special permit.

Portable tanks, IBCs, cargo tanks, and tank cars

- Marking requirements are applicable to various types of tanks, containers, and tank cars.

Portable tanks

In addition to displaying the applicable identification number, portable tanks must be marked with:

- Material’s proper shipping name — on two opposite sides. For water transport the size of the shipping name must be 65 mm or more.

- Owner's or lessee’s name.

IBCs

When an intermediate bulk container (IBC) is labeled instead of placarded, the IBC may display the proper shipping name and identification number markings as required by 172.301(a)(1) for non-bulk packagings. These smaller markings may be used in place of the identification number marking on an orange panel, placard, or white square-on-point configuration.

Cargo tanks

In addition to the identification number, cargo tanks (except for certain nurse tanks) that are used to transport gases (Class 2 material) must be marked on each side and each end with the proper shipping name or appropriate common name of the gas.

Each specification cargo tank that successfully completes a test/inspection must be marked with the date (month and year) and the type of test/inspection completed. This marking must be displayed near the specification plate or anywhere on the front head. The type of test/inspection may be abbreviated as follows:

- V for external visual inspection/test

- I for internal visual inspection

- P for pressure test

- L for lining inspection

- T for thickness test

- K for leakage test

- K-EPA27 for U.S. Environmental Protection Agency (EPA) Method 27 leakage test

Tank cars

In addition to the identification number, tank cars — when required by a special provision to the Hazardous Materials Table or by 172.330 — must be marked on each side with the proper shipping name or appropriate common name.

In addition to the identification number marking, multi-unit tank car tanks must be marked on two opposing sides with the proper shipping name or appropriate common name.

Shipping name changes

- Markings are directly affected by factors including altered shipping names.

If the proper shipping name for a hazardous material in a bulk packaging has been changed, the bulk packaging may not need to be remarked if:

- The bulk packaging was marked before October 1, 1991, in conformance with the Hazardous Materials Regulations (HMR) in effect on September 30, 1991; and

- The marking contains the same key words as the current proper shipping name in the Hazardous Materials Table.

Markings for sour crude oil

- Petroleum sour crude oil packagings and limited quantities must be marked a certain way.

A bulk packaging used to transport petroleum crude oil containing hydrogen sulfide (sour crude oil) in sufficient concentrations that the vapors may present an inhalation hazard must be marked with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) toxic pictogram or a warning statement such as “Danger: Possible Hydrogen Sulfide Inhalation Hazard.” The marking must be displayed at each location (manhole, loading head) where exposure to hydrogen sulfide vapors may occur.

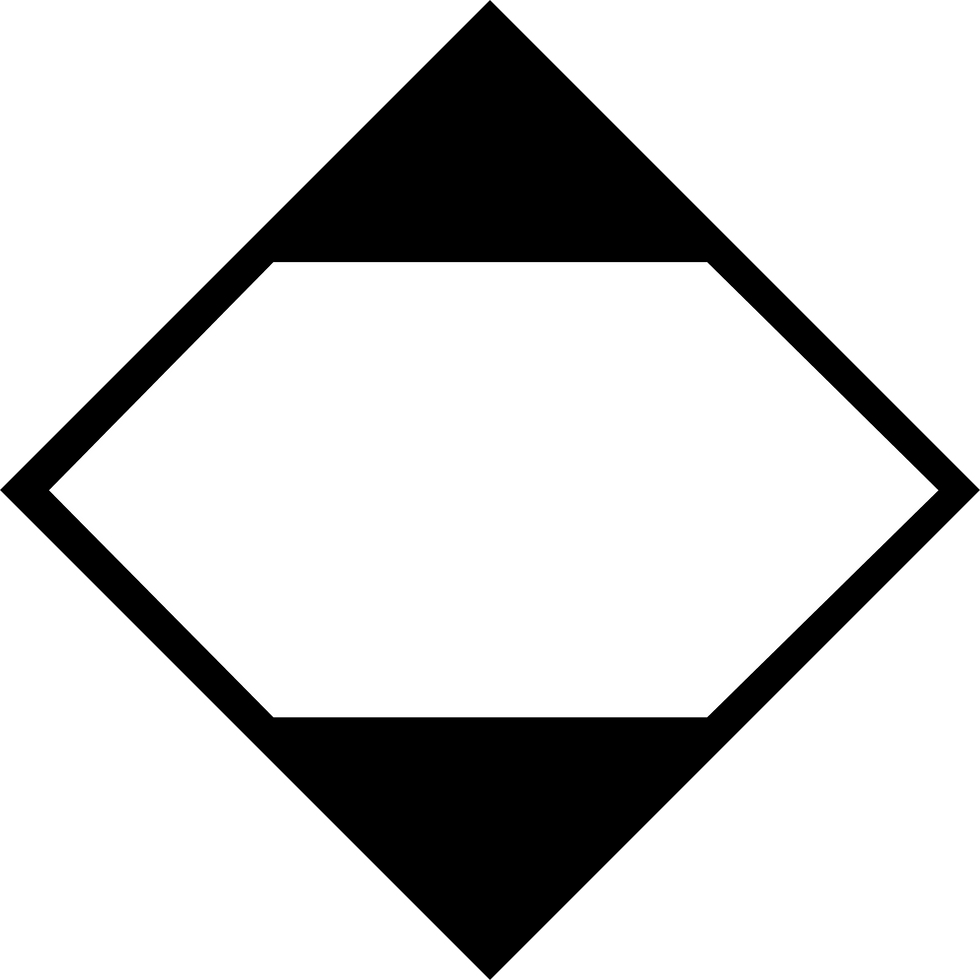

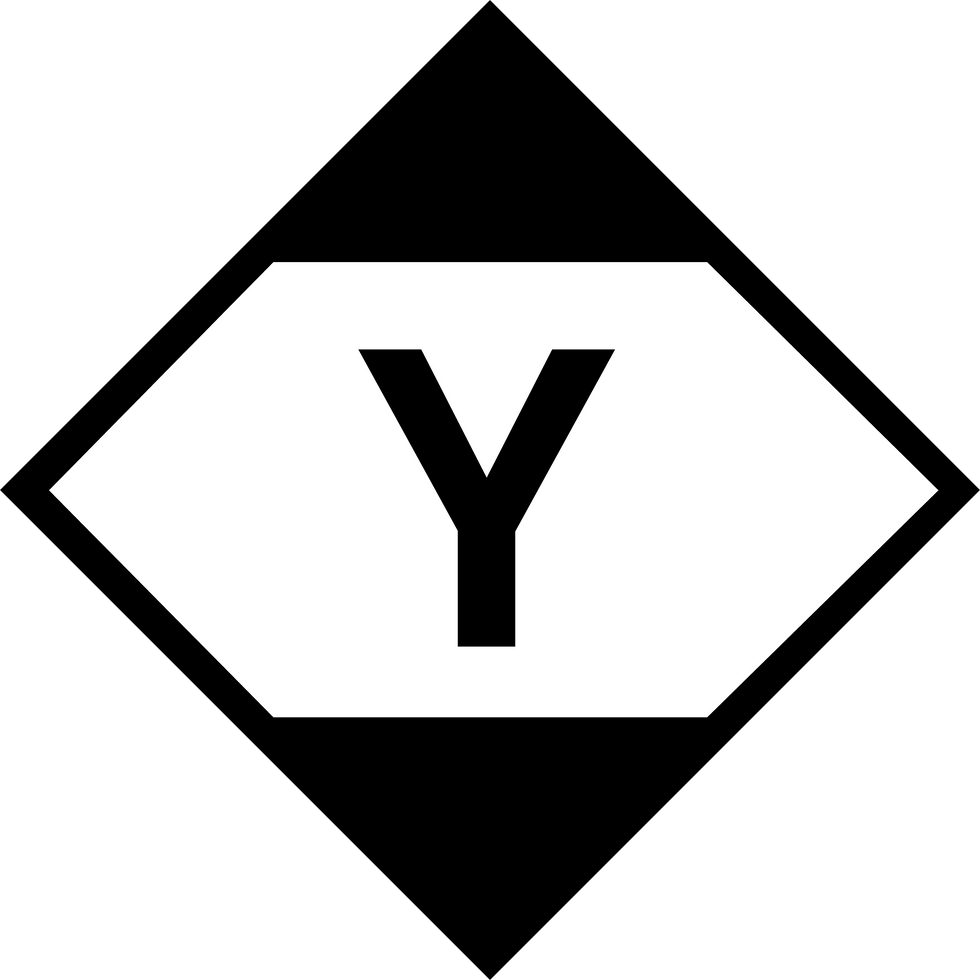

Limited quantity markings

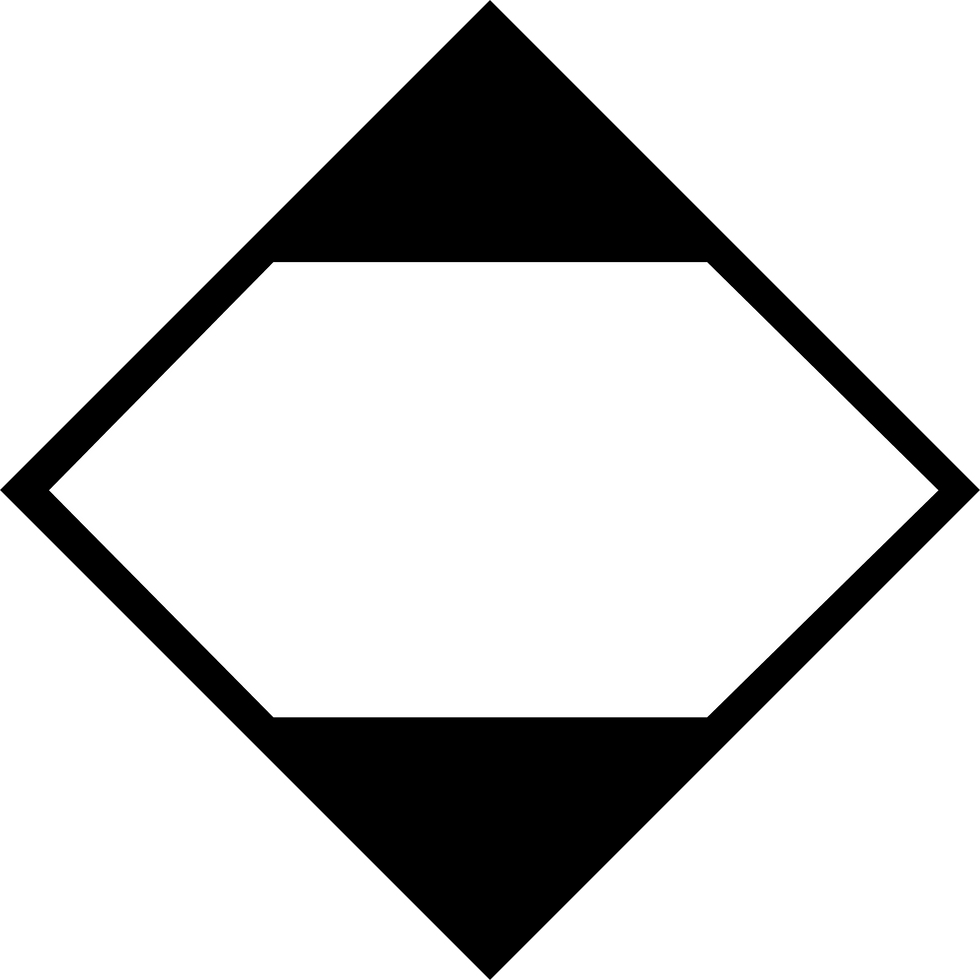

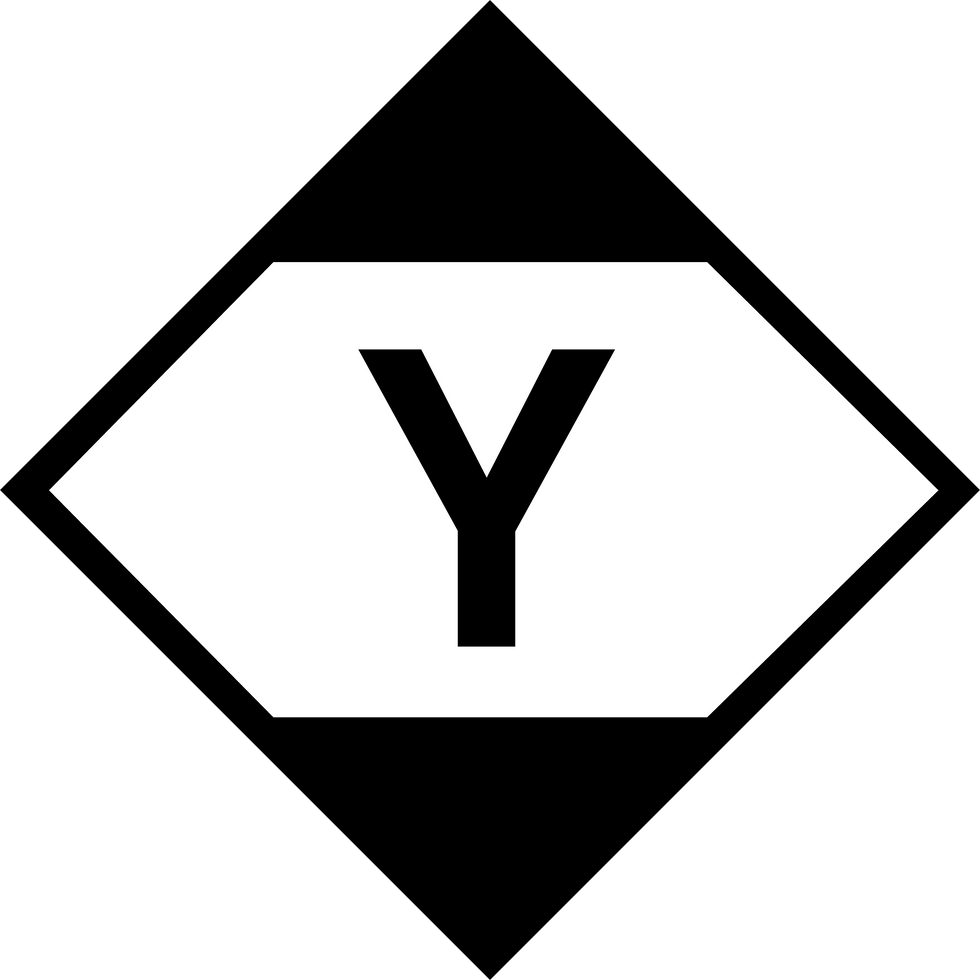

A package containing a limited quantity of hazardous materials is required to be marked with one of the following:

- Non-air packages containing a limited quantity must display the square-on-point limited quantity marking. A package displaying the limited quantity marking is not required to be marked with the proper shipping name or identification number, unless the material is a hazardous substance or hazardous waste.

- Packages meeting the requirements for air transport must display the square-on-point “Y” limited quantity marking. A package displaying the “Y” limited quantity marking is required to be marked with the proper shipping name and identification number when transported by air. Packages displaying the square-on-point “Y” limited quantity marking are authorized for transport by all modes of transportation.

The width of the border forming the square-on-point marking must be at least 0.08 inches (2 mm). Each side of the marking must be at least 3.94 inches (100 mm). If the package size requires a reduced size marking, then each side of the marking may be reduced to no less than 1.97 inches (50 mm). For cargo transport units transported by water, each side of the marking must have a minimum size of 9.84 inches (250 mm).

Markings for hazardous wastes, orientation arrow markings, and inhalation hazards

- The nature of the hazardous material being transported and the kind of package used can determine whether additional markings are necessary.

- The list of material categories that might need additional markings includes hazardous wastes, orientation arrow markings, and inhalation hazards.

Additional markings may be required depending on the hazardous material being transported or the type of package used.

Hazardous wastes

Proper shipping names marked on non-bulk packages of hazardous waste are not required to include the word “waste” if the U.S. Environmental Protection Agency (EPA) marking is displayed in accordance with 40 CFR Section 262.32.

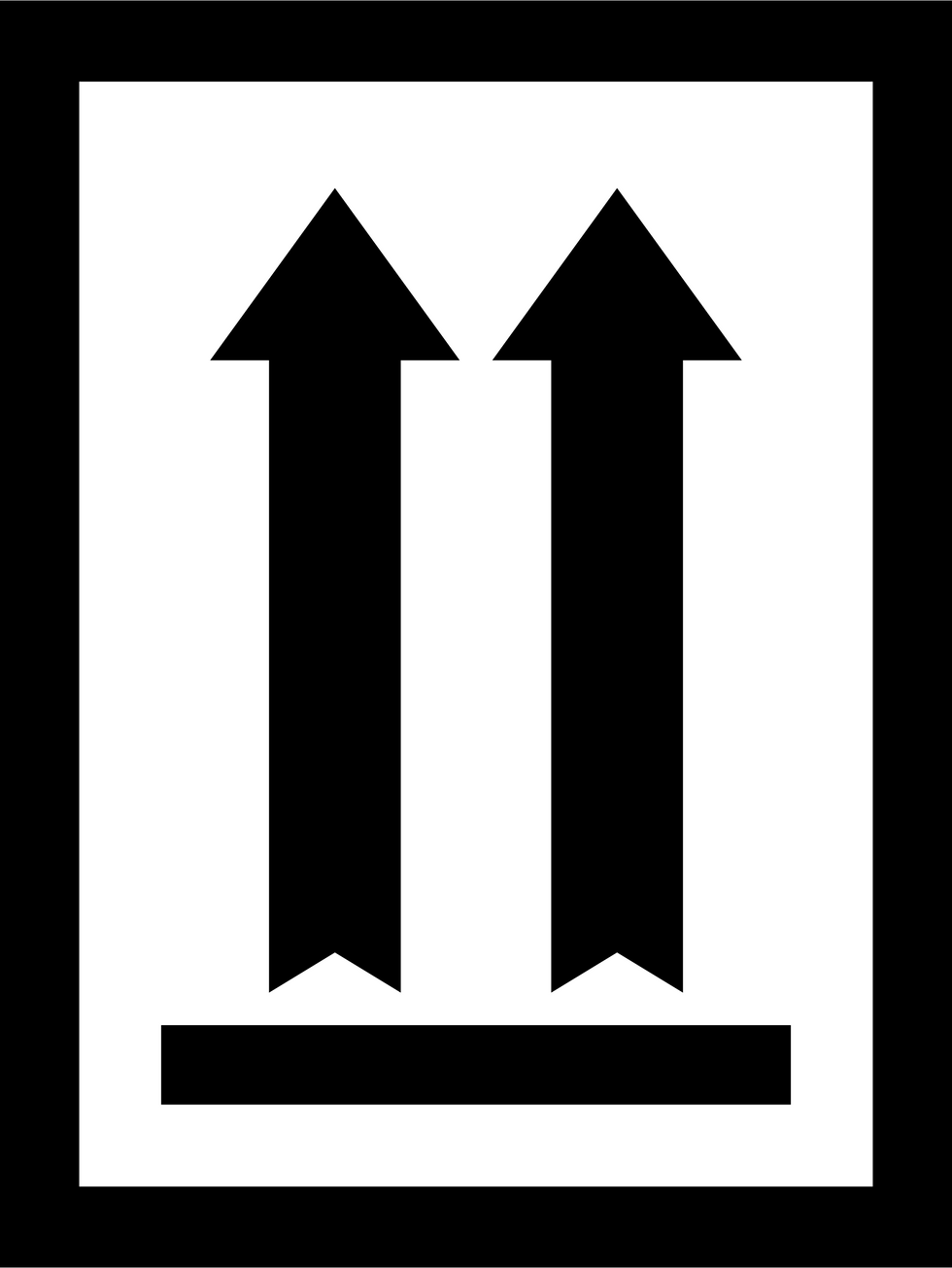

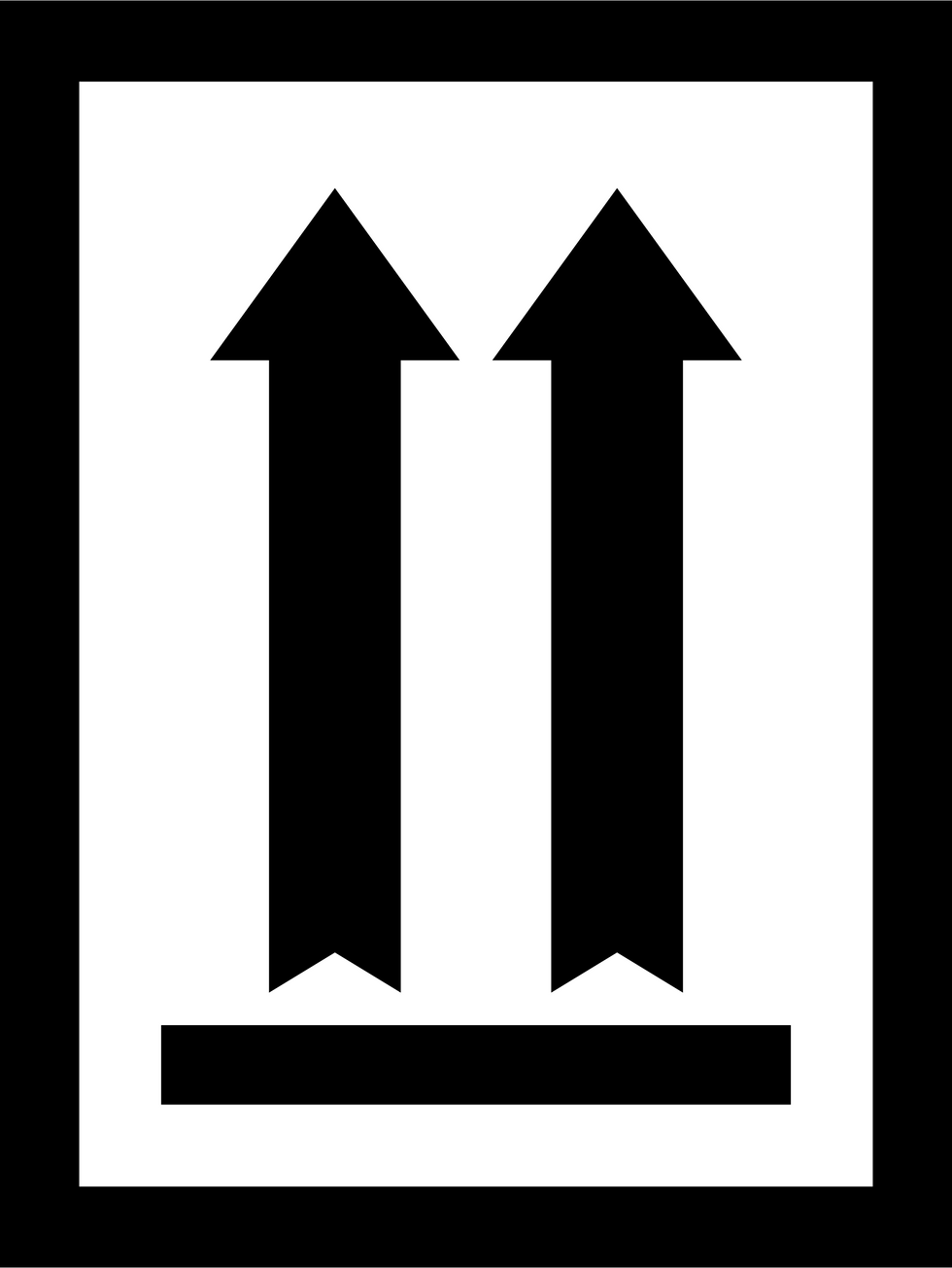

Orientation arrow markings

Combination packagings that have inner packagings containing liquid hazardous materials, single packaging fitted with vents, or open cryogenic receptacles must be marked with orientation arrows. These arrows must be displayed on two opposite vertical sides of the packaging — with the arrows pointing in the correct upward direction.

Orientation arrows are not required on packages that contain:

- Inner packagings of cylinders;

- Flammable liquids in inner packagings of 33.81 fluid ounces (1 L) or less prepared as a limited quantity or consumer commodity, except for transport by air;

- Flammable liquids in inner packagings of 4 fluid ounces (120 mL) or less prepared as a limited quantity or consumer commodity, when packed with sufficient absorption material between the inner and outer packagings to completely absorb the liquid contents, when transported by air;

- Liquids contained in manufactured articles (e.g., alcohol or mercury in thermometers) that are leak-tight in all orientations;

- Hermetically sealed inner packagings; or

- Liquid infectious substances in primary receptacles not exceeding 1.7 ounces (50 mL).

Inhalation hazards

Packagings that contain materials poisonous-by-inhalation must be marked “INHALATION HAZARD” in association with required labels or placards or the proper shipping name. The “INHALATION HAZARD” marking is not required if the package bears a poison gas or poison inhalation hazard label (or placard) displaying the words “INHALATION HAZARD.”

This marking on bulk packages must be on two opposite sides and have:

- A minimum width of 0.24 inches (6 mm) and a minimum height of 3.9 inches (100 mm) for rail cars,

- A minimum width of 0.16 inches (4 mm) and a minimum height of 1 inch (25 mm) for portable tanks with capacities of less than 1,000 gallons (3,785 L) and intermediate bulk containers, and

- A minimum width of 0.24 inches (6 mm) and a minimum height of 2 inches (50 mm) for cargo tanks and other bulk packagings.

Markings for poisons, materials to keep away from heat, explosive materials, and marine pollutants

- Packaged materials that pose specific dangers must be appropriately marked.

Poisons

Non-bulk plastic outer packagings used as single or composite packagings for Division 6.1 materials must be permanently marked with the word “POISON” — either by embossing or other durable means. This marking must be at least 0.25 inches (6.3 mm) in height and located within 6 inches (150 mm) of the closure of the packaging.

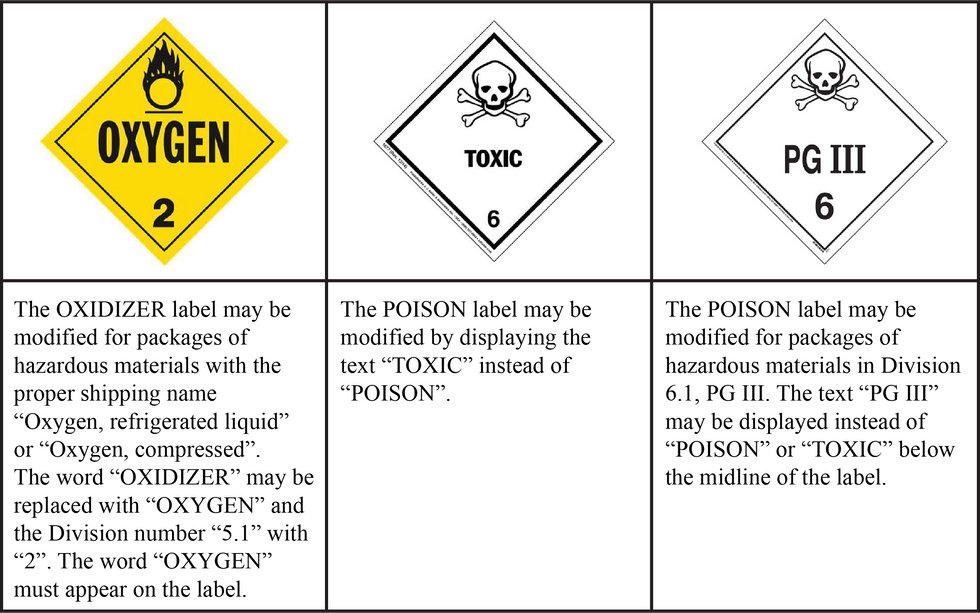

A package containing a Division 6.1 (poison) material in Packing Group III may be marked “PG III” adjacent to the “POISON” label.

Keep away from heat (172.(317)

For transportation by aircraft, packages containing self-reactive substances of Division 4.1 or organic peroxides of Division 5.2 must be marked with the “KEEP AWAY FROM HEAT” handling mark. This marking must be at least 4.1 inches (105 mm) in height and 2.9 inches (74 mm) in width.

Explosive materials (172.320)

A package of Class 1 material must be marked with the EX-number for each substance, article, or device contained therein unless it is excepted from this marking as specified in 172.320. In some situations, no marking is required; for others, a national stock number or product code may be used.

When more than five different Class 1 materials are packed in the same package, no more than five of the numbers, codes, or a combination thereof are required to be marked on the package.

Marine pollutants

Non-bulk packagings that contain marine pollutants and are offered for transportation by vessel must be marked with:

- The name of the component(s) in parentheses that make the material a marine pollutant — if the proper shipping name does not identify the component(s); and

- The marine pollutant mark, in association with the required hazard warning label(s) or in the absence of labels, in association with the proper shipping name.

The marine pollutant marking is not required on single packagings or combination packagings where each single package or each inner packaging of combination packagings has:

- A net quantity of 1.3 gallons (5 L) or less for liquids, or

- A net mass of 11 pounds (5 kg) or less for solids.

The marine pollutant marking is not required on a combination packaging containing a marine pollutant (other than a severe marine pollutant) in inner packagings, each of which contains:

- 1.3 gallons (5 L) or less net capacity for liquids, or

- 11 pounds (5 kg) or less net capacity for solids.

Non-bulk packagings of marine pollutants transported by motor vehicle, rail car, or aircraft are not subject to marine pollutant requirements.

Bulk packagings with a capacity of 1,000 gallons (3,785 L) or more and that contains marine pollutants must be marked on each side and each end with the marine pollutant marking. A bulk packaging with a capacity of less than 1,000 gallons (3,785 L) must be marked on two opposing sides or ends with the marine pollutant marking.

Did you know?

Except for transportation by vessel, a bulk packaging, freight container, or transport vehicle that bears a label or placard is not required to display the marine pollutant marking.

A package of limited quantity material that is marked with a square-on-point limited quantity marking is not required to display the marine pollutant marking.

The symbol and border must be black on a white background, or be of a contrasting color to the surface on which the marking is displayed. The width of the border must be at least 0.08 inches (2 mm). Each side of the marking must be at least 3.9 inches (100 mm) for non-bulk packages and bulk packages with a capacity of less than 1,000 gallons (3,785 L). For all other bulk packages, each side of the marking must be at least 9.8 inches (250 mm).

Markings for elevated-temperature, radioactive materials, medical waste, and LPG

- Bulk packages are required to have specific markings for various types of high-temperature or radioactive materials, as well as medical waste and LPG.

Elevated-temperature materials

Most bulk packages that contain an elevated-temperature material must be marked on two opposing sides with the word “HOT” — in black or white Gothic lettering on a contrasting background. This marking must be displayed on the packaging itself or in black lettering on a white square-on-point configuration that is the same size as a placard.

Bulk packages that contain molten aluminum or molten sulfur must be marked “MOLTEN ALUMINUM” or “MOLTEN SULFUR” as appropriate, instead of with the word “HOT.

For bulk packages that must be marked “HOT,” “MOLTEN ALUMINUM,” or “MOLTEN SULFUR,” the letters must be at least:

- 3.9 inches (100 mm) for rail cars,

- 1 inch (25 mm) for portable tanks with capacities of less than 1,000 gallons (3,785 L), and

- 2 inches (50 mm) for cargo tanks and other bulk packages.

The Hazardous Materials Regulations (HMR) allows the “HOT” marking and identification number marking to be combined on the same white square-on-point configuration (Placard). In this case, the identification number must be displayed in the center of the white square-on-point configuration, and the word “HOT” must be displayed in the upper corner. The word “HOT” must be in black letters having a height of at least 2 inches (50 mm).

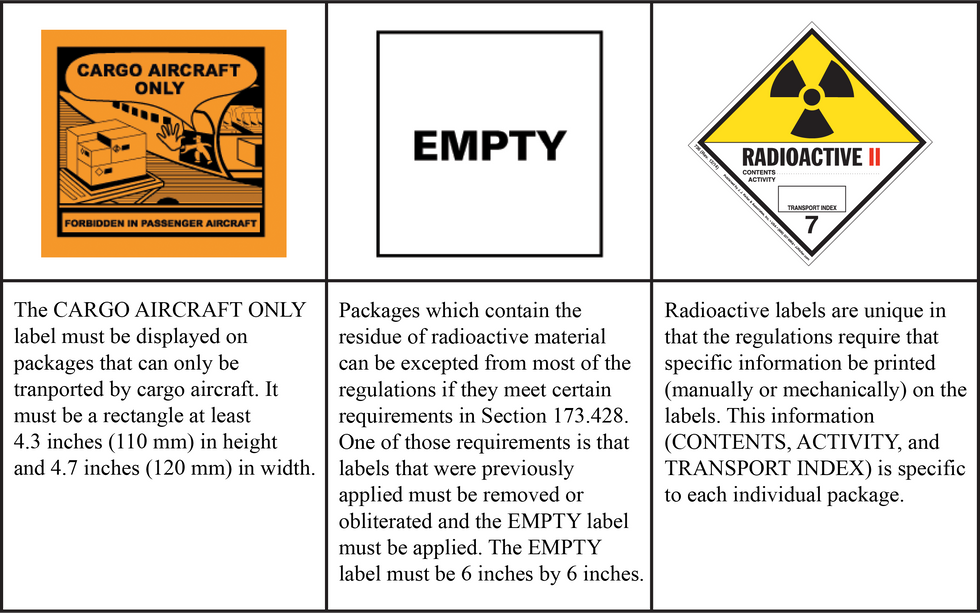

Radioactive materials (172.310)

Each package containing Class 7 (radioactive) materials must also be marked with:

- Gross mass if the gross mass of the package exceeds 110 pounds (50 kg);

- TYPE A or TYPE B, as appropriate;

- For TYPE B(U) or B(M), the appropriate radiation symbol according to Appendix B to Part 172; and

- USA in conjunction with the specification marking, if the package is destined for export.

Regulated medical waste (172.323)

A bulk packaging containing a regulated medical waste must be marked with the “BIOHAZARD” marking, visible from the direction it faces:

- On two opposing sides or ends if the packaging has a capacity of less than 1,000 gallons (3,785 L), or

- On each end and each side if the packaging has a capacity of 1,000 gallons (3,785 L) or more.

The “BIOHAZARD” marking must be at least 6 inches (152.4 mm) on each side. This marking may be displayed on a white square-on-point configuration.

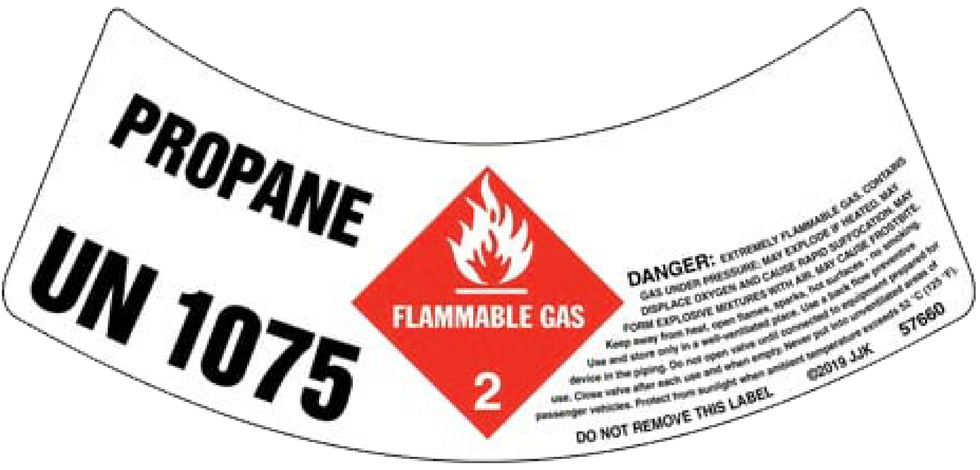

Non-odorized LPG (172.301, 172.326, 172.328, 172.330)

No person may offer or transport certain specification cylinders, a portable tank, cargo tank, or tank car containing liquefied petroleum gas (LPG) that is not odorized unless the words “NON-ODORIZED” or “NOT ODORIZED” appear near the proper shipping name. This marking must appear on two opposing sides on portable tanks, cargo tanks, and tank cars.

Markings for overpacks and fumigants

- Special markings requirements are in place for use of overpacks and fumigants.

Overpacks

Each overpack:

- Must be marked with the proper shipping names and identification numbers of the materials contained within, unless markings on the inside packages are visible;

- That contains packages subject to orientation marking requirements must be marked with orientation arrows on two opposite vertical sides, with the arrows pointing in the correct upward direction;

- Must be marked with the word “OVERPACK” indicating that the inner packages comply with prescribed specifications (when specification packagings are required), unless specification markings on the inside packages are visible;

- Containing packages of limited quantity materials must be marked “OVERPACK,” unless all required markings are visible through the overpack; and

- Containing excepted quantities must be marked with the required markings for the inside packages, unless all required markings are visible through the overpack. Overpacks of excepted quantities are not required to be marked “OVERPACK.”

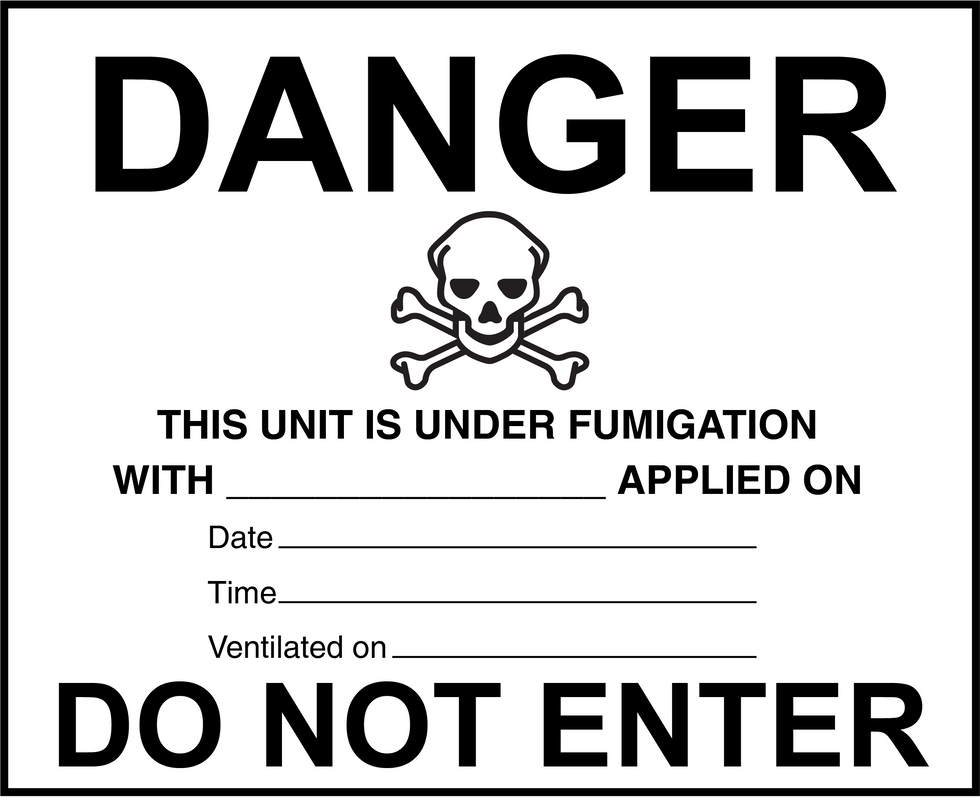

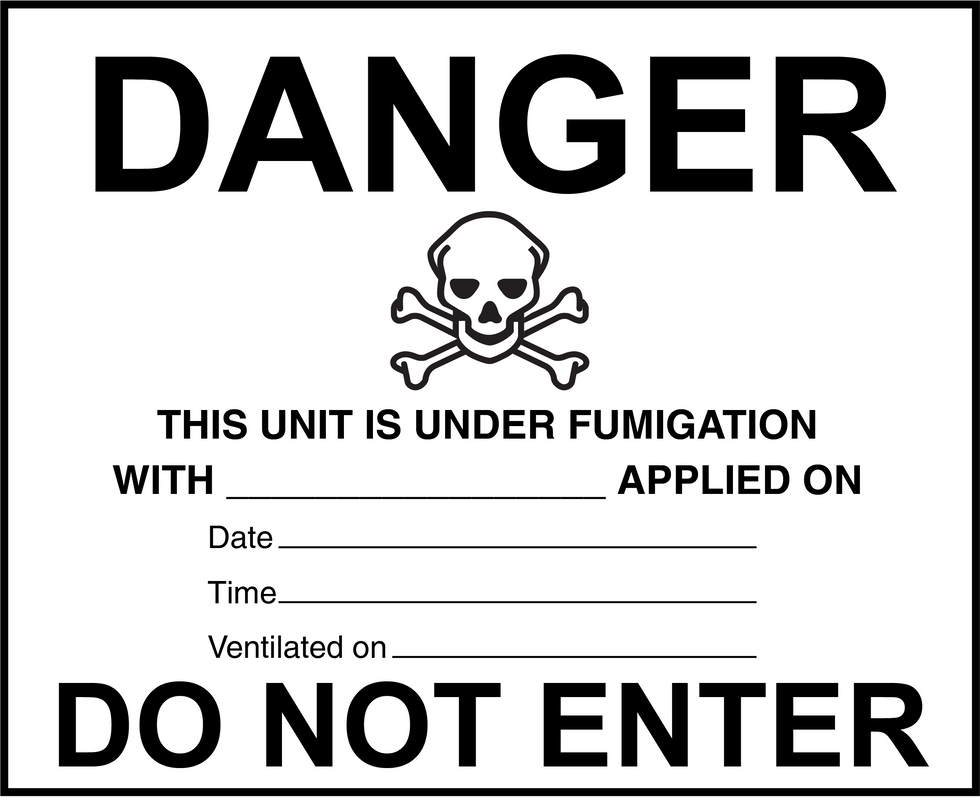

Fumigant marking

Each truck body or trailer, rail car, or freight container containing lading that has been fumigated or treated with any material, or is undergoing fumigation, must have a “FUMIGANT” marking displayed so it can be seen by any person attempting to enter the vehicle or container.

The printing on the “FUMIGANT” marking must be black on a white background. The size of the white background must be at least 15.75 inches (400 mm) wide and at least 11.8 inches (300 mm) high. The width of the border must be at least 0.08 inches (2 mm). Text on this marking must be at least 0.98 inches (25 mm). The technical name of the fumigant must be entered in the appropriate place (*) on the marking.

The “FUMIGANT” marking must be displayed until the truck body or trailer, rail car, or freight container has been completely ventilated.

Reverse logistics, small quantities, and excepted quantities

- Requirements and exceptions affect the process of reverse logistics, as well as packages containing small quantities and excepted quantities.

Reverse logistics

Reverse logistics is the offering or transporting of goods by motor vehicle from a retail store for return to the manufacturer, supplier, or distribution facility for the purpose of capturing value (credit), recall, replacement, recycling, or similar reason. This does not include hazardous waste.

Materials involved in reverse logistics are excepted from many of the Hazardous Materials Regulations (HMR). However, shipments of reverse logistics materials must be marked with the limited quantity marking or the words “REVERSE LOGISTICS – HIGHWAY TRANSPORT ONLY – UNDER 49 CFR 173.157.”

Small quantities (173.4)

When transported by highway or rail only, packages containing small quantities of materials meeting the requirements in Section 173.4 must be marked with the statement “This package conforms to 49 CFR 173.4 for domestic highway or rail transport only.”

Excepted quantities (173.4a)

When transported by air or vessel only, packages containing excepted quantities of materials meeting the requirements in Section 173.4a must be marked with the excepted quantities marking. The “*” must be replaced with the hazard class or division of each hazardous material in the package. The “**” must be replaced with the name of the shipper or consignee, if not shown elsewhere on the package. The hatching must be the same color, black or red on a contrasting background. The marking must be 3.9 inches (100 mm) by 3.9 inches (100 mm).

Placards

- Entities involved in shipping hazardous materials must comply with placarding requirements outlined by the HMR.

Hazardous materials placards correspond closely with the shape, color, and design of hazardous materials labels. However, placards are much larger than labels. Placards alert people to potential dangers associated with the particular hazardous material contained in a motor vehicle, railcar, freight container, cargo tank, or portable tank.

Anyone offering or accepting hazardous materials for shipment in an amount that requires placards must ensure the material is placarded according to applicable sections of the Hazardous Materials Regulations (HMR).

Placarding requirements apply to each person who offers for transport or transports hazardous materials. The placarding requirements do not apply to the following materials:

- Infectious substances (Division 6.2);

- Materials authorized to be transported as a limited quantity (when properly identified on shipping papers or marked in accordance with 172.315);

- Materials packaged as “small quantities” (under provisions of 173.4, 173.4a, or 173.4b);

- Materials prepared in accordance with 173.13 (exceptions for Classes 3, 8, 9, and Division 4.1, 4.2, 4.3, 5.1, 6.1); and

- Combustible liquids in non-bulk packagings.

Placards are used to identify the hazard or hazards of materials contained in bulk packagings, freight containers, unit load devices, transport vehicles, or rail cars.

Responsibility

Responsibility for affixing or supplying placards varies according to mode of transport and type of packaging used to transport the hazardous material.

For highway transport, the shipper is responsible for providing the appropriate placards to the driver. The driver is responsible for applying them correctly on the vehicle and maintaining them during transport. In addition, drivers are responsible for any placarding necessitated by aggregate shipments.

Bulk packagings (172.514)

The person who offers a bulk packaging containing a hazardous material for transportation is required to affix the required placards before or at the time the packaging is offered for transportation.

Freight containers and aircraft unit load devices (172.512)

Each person who offers for transportation and each person who loads and transports a hazardous material in a freight container or aircraft unit load device is required to affix the appropriate placards.

Transport vehicles (172.506, 177.823)

When a hazardous material is offered for transport by highway, the individual offering the material must provide the carrier with the required placards — before or at the same time the material is offered for transport — unless the appropriate placards are already affixed to the vehicle.

Typically, the carrier is forbidden from moving the vehicle until placards have been affixed. However, the carrier may move the vehicle before placarding in an emergency situation or when one of the following three conditions are met:

- The vehicle is escorted by a representative of state or local government,

- The carrier has received permission from the U.S. Department of Transportation (DOT) to move the vehicle, or

- Movement of the vehicle is necessary to protect life and property.

Rail cars (172.508)

When a hazardous material is offered for transport by rail, the individual offering the material must affix the required placard(s) to the railcar — unless the car is already properly placarded. The rail carrier may not accept a railcar for transport unless required placards are affixed.

Prohibited placarding and placarding requirements

- Placards affixed to equipment or packaging must meet HMR requirements; signs, advertisements, and slogans cannot be used for that purpose.

Prohibited placarding (172.502)

No person may affix a placard to a packaging, a freight container, a unit load device, a motor vehicle, or a railcar unless the material being offered for transportation is a hazardous material, the placard applied represents the hazard of the material being offered, and the placards conform to requirements in the Hazardous Materials Regulations (HMR).

Signs, advertisements, slogans (such as “Drive Safely”), or other devices that could be confused with a prescribed placard are prohibited.

Permissive placarding (172.502)

Placards may be displayed for a hazardous material, even when not required, if the hazardous material is present and the placarding conforms to regulations.

A bulk packaging, freight container, unit load device, transport vehicle, or rail car placarded according to Canada’s Transport Dangerous Goods (TDG) Regulations, the International Maritime Dangerous Goods (IMDG) Code, or the United Nations (UN) Recommendations is allowed.

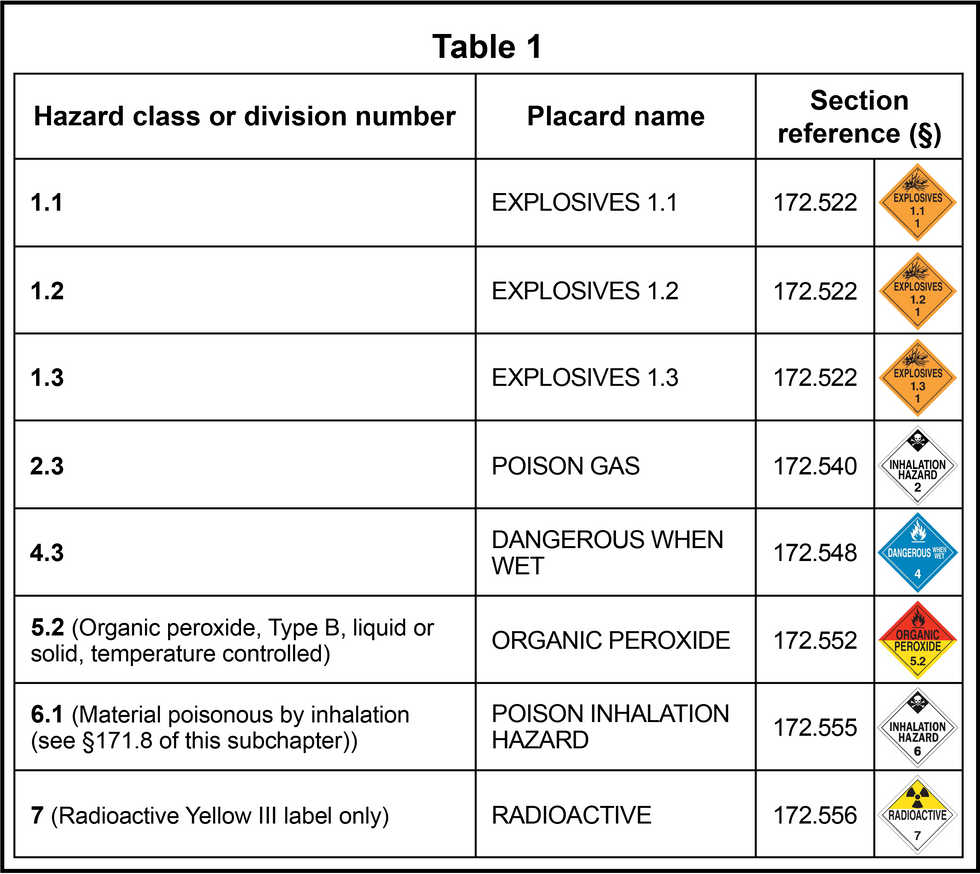

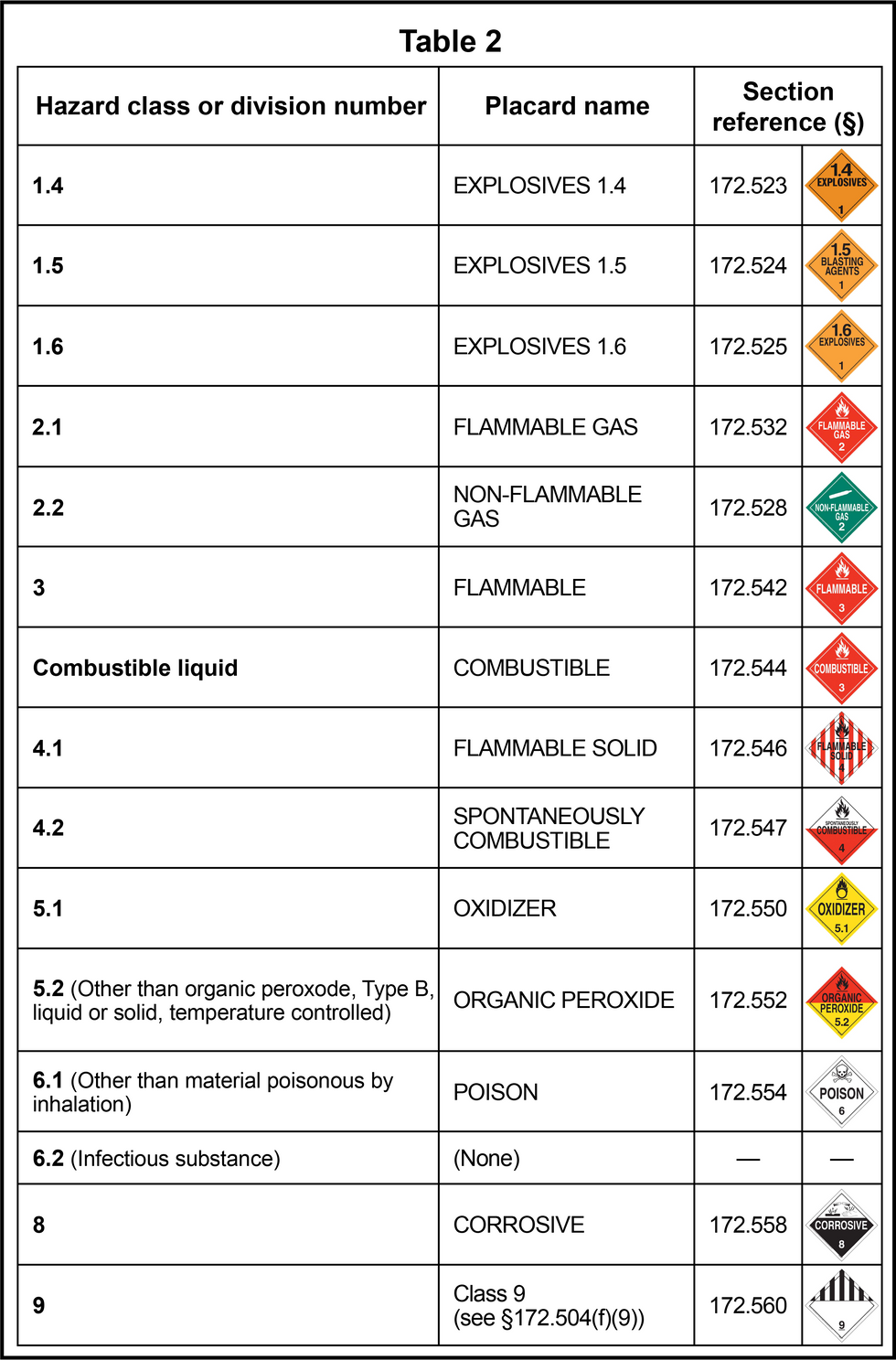

Placarding tables (172.504)

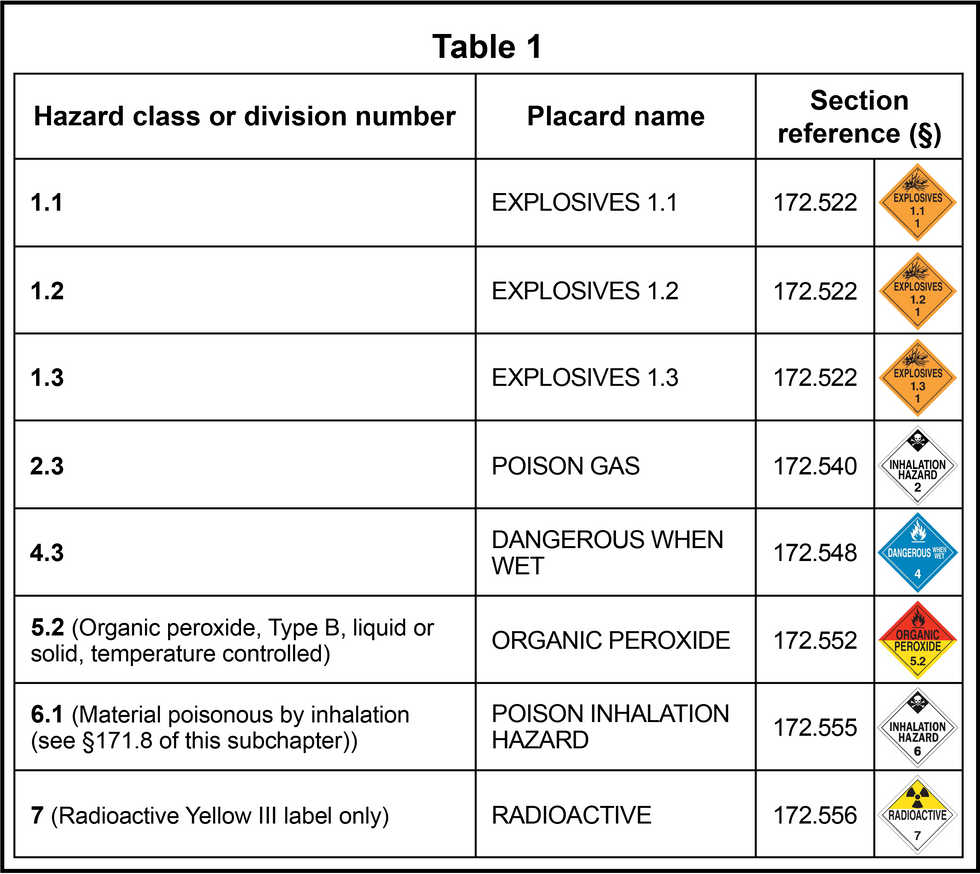

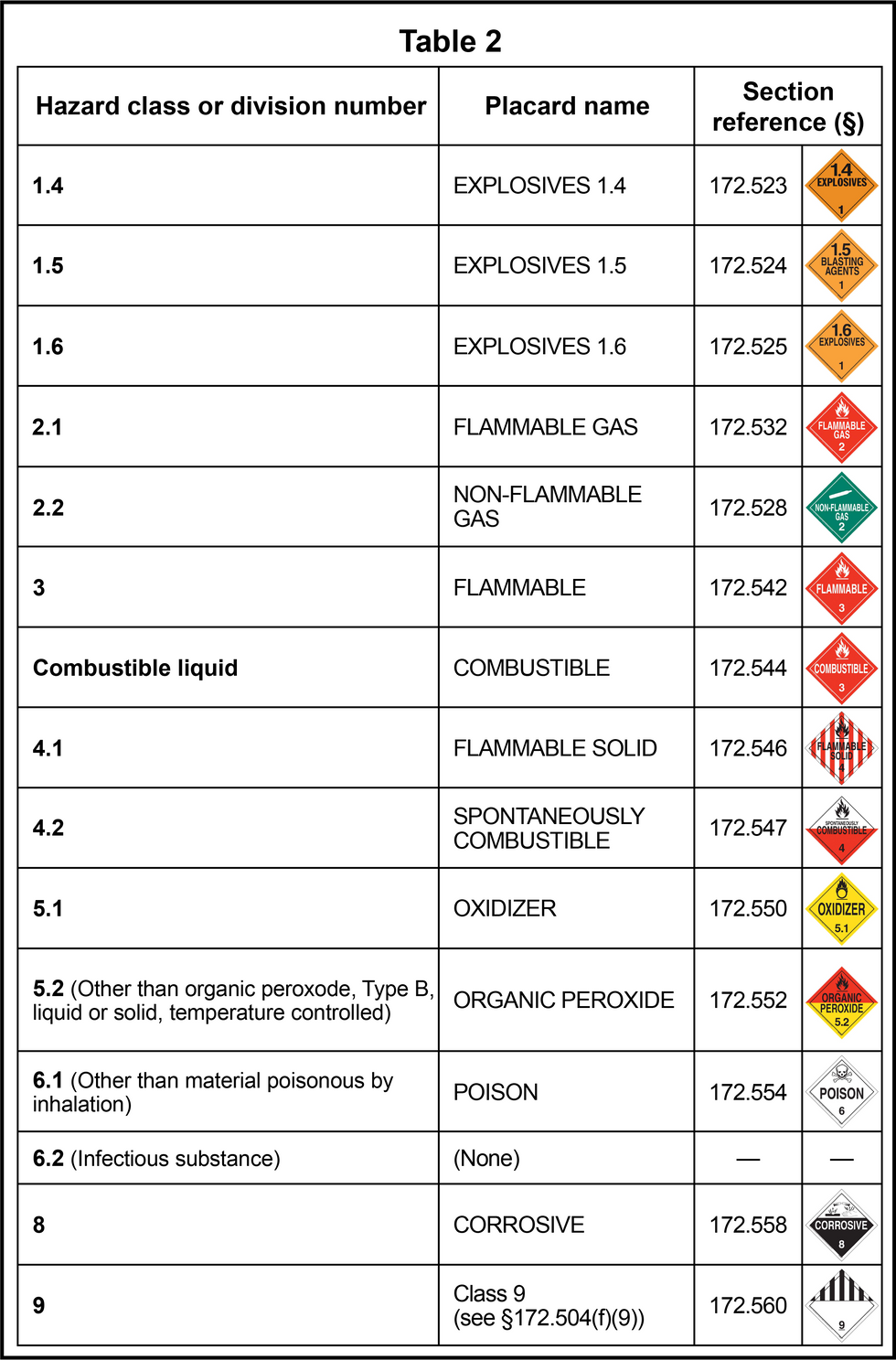

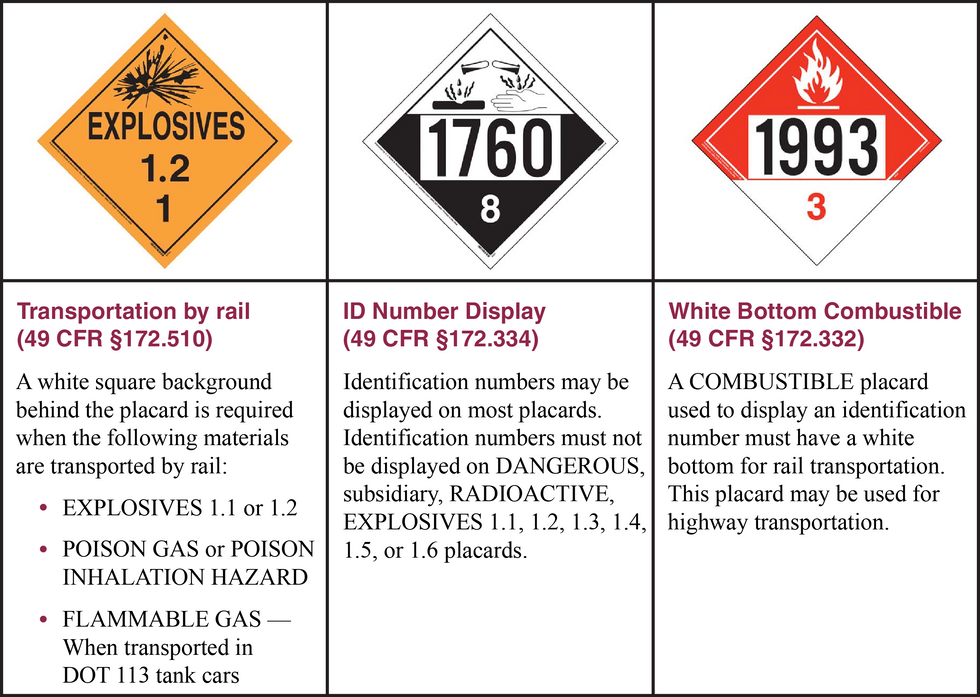

Placarding requirements vary according to the category of material (hazard class, division, packing group, or description) being transported and type of packaging (bulk or non-bulk) containing the material. Each bulk packaging, freight container, unit load device, transport vehicle, or rail car containing hazardous material must be placarded on each side and each end (with some exceptions) with the type of placards specified in Table 1 or Table 2 of Section 172.504.

To determine what placards are required, one must know:

- The type of packaging (bulk or non-bulk) containing the hazardous material(s);

- The hazard category (class, division, packing group, or description) and subsidiary hazard(s) of the hazardous material(s) present; and

- The weight of non-bulk packages in each hazard category.

The most dangerous categories of hazardous materials are shown in Table 1 of 172.504. Any quantity of material falling within the categories listed in Table 1 must be placarded.

The remaining hazard categories are assigned to Table 2. Any quantity of these materials also must be placarded, but the regulations provide some exceptions under certain conditions.

What exceptions apply to placarding?

- Placarding exceptions apply to the requirements for placards only; the placarding exceptions are not sweeping exceptions from all HMR.

- A commonly used placarding exception can be used when transporting less than 1,001 pounds of non-bulk Table 2 materials.

Less than 1,001 pounds of Table 2 materials

A transport vehicle or freight container that contains less than 1,001 pounds (454 kg) aggregate gross weight of hazardous materials in non-bulk packages covered by Table 2 is not required to display placards. This exception does not apply to bulk packages or materials with subsidiary hazards that must be placarded according to 172.505.

Did you know?

A Class 9 placard is not required for domestic transportation. However, a bulk packaging must be marked with the appropriate identification number as required by the Hazardous Materials Regulations (HMR).

If a transport vehicle, railcar, freight container, or unit load device contains non-bulk packagings of two or more categories of Table 2 materials, the “DANGEROUS” placard may be displayed instead of the separate placards specified in Table 2.

When 2,205 pounds (1,000 kg) or more of one hazard category is loaded at one facility on one vehicle, railcar, freight container, or unit load device, the “DANGEROUS” placard cannot be used for that one hazard category; instead, the placard specified in Table 2 must be displayed.

If three or more different categories of Table 2 materials are in one vehicle, railcar, freight container, or unit load device, and one material is over the 2,205-lb (1,000-kg) limit and requires an individual class placard, the “DANGEROUS” placard may still be used for the other categories of Table 2 material that fall below the 2,205-lb (1,000-kg) limit.

Placard exceptions by hazard class

Class 1 (172.504)

When more than one division placard is required for Class 1 materials on a transport vehicle, rail car, freight container, or unit load device, only the placard representing the lowest division number must be displayed.

The “EXPLOSIVES” 1.4 placard is not required for those Division 1.4 Compatibility Group S (1.4S) materials that are not required to be labeled 1.4S.

For shipments of Class 1 (explosive) materials by aircraft or vessel, the applicable compatibility group letter must be displayed on the required placards.

Gases (172.504)

A “NON-FLAMMABLE GAS” placard is not required on a motor vehicle containing a non-flammable gas if the vehicle contains flammable gas or oxygen and is placarded “FLAMMABLE GAS” or “OXYGEN,” as required.

The “OXYGEN” placard may be used for domestic shipments of oxygen, compressed or oxygen, refrigerated liquid in place of a “NON-FLAMMABLE GAS” placard.

Flammables (172.504)

A “COMBUSTIBLE” placard is not required on a cargo tank, portable tank, or compartmented tank car containing both flammable and combustible liquids when placarded “FLAMMABLE.”

Oxidizers (172.504)

“OXIDIZER” placards are not required for Division 5.1 materials on freight containers, unit load devices, transport vehicles, or rail cars that also contain Division 1.1 or 1.2 materials and are placarded with “EXPLOSIVES” 1.1 or 1.2 placards, as required.

For transportation by transport vehicle or railcar only: An “OXIDIZER” placard is not required for Division 5.1 materials on a transport vehicle, railcar, or freight container that also contains Division 1.5 materials and is placarded with “EXPLOSIVES” 1.5 placards, as required.

Poisons (172.504)

For domestic transportation:

- A “POISON” placard is not required on a transport vehicle or freight container required to display a “POISON INHALATION HAZARD” or “POISON GAS” placard, and

- A “POISON INHALATION HAZARD” placard is not required on a transport vehicle or freight container that is already placarded with a “POISON GAS” placard.

For Division 6.1, Packing Group III materials, a “POISON” placard may be modified to display the text “PG III” below the midline of the placard in place of the word “POISON.”

Class 9 (172.504)

Class 9 placards are not required for domestic transportation.

Freight containers/unit load devices and placards for rail (172.512)

A motor vehicle transporting freight containers or aircraft unit load devices that are not required to be placarded is not required to display placards.

Freight containers and unit load devices being transported for delivery to a consignee immediately after an air or water shipment are also allowed to use the exception for less than 1,001 pounds (454 kg) of Table 2 materials.

A freight container or aircraft unit load device that is only transported by air and is prepared according to Part 7, Chapter 2, Section 2.8 of the International Civil Aviation Organization (ICAO) Technical Instructions is not required to be placarded.

Rail (172.504)

A railcar loaded with a transport vehicle or freight container that is not required to be placarded is not required to display placards.

Types of placards and placard specifications

- Primary and subsidiary placards may need to be displayed, depending on materials being transported.

- Every placard needs to adhere to several criteria in order to be fully compliant.

Primary and subsidiary placards

There are two types of placards:

- Primary placards indicate the primary hazard of the material, and

- Subsidiary placards indicate additional hazards the material possesses.

Generally, only primary placards are displayed. Section 172.505 of the Hazardous Materials Regulations (HMR) requires additional placards to be displayed under certain conditions for several subsidiary hazards. This includes “POISON GAS,” “POISON INHALATION HAZARD,” “POISON,” “CORROSIVE,” and “DANGEROUS WHEN WET.” Other subsidiary placards are permitted to be displayed but are not required.

Placard specifications

To be in compliance, all placards must meet the following specifications:

- Placards must be designed as specified in Part 172, Subpart F.

- Specifications for color must be as prescribed in Appendix A to Part 172.

- Placards must measure at least 9.84 inches (250 mm) on each side and have a solid-line inner border approximately 0.49 inches (12.5 mm) inside and parallel to the edge.

- Other than for the “RADIOACTIVE” or “DANGEROUS” placard, text indicating the hazard (e.g., “FLAMMABLE”) is not required. Text is not required on the “OXYGEN” placard only when an identification number is displayed.

- Placards may contain form identification information — including the name of the maker — if such information is printed outside of the solid-line inner border in no larger than 10-point type.

- Reflective and retro-reflective material may be used on a placard if color, strength, and durability requirements are maintained.

- Material used for placards may be any plastic, metal, or other material capable of withstanding, without deterioration or a substantial reduction in effectiveness, a 30-day exposure to open-weather conditions.

Tagboard placards must:

- Be of a quality at least equal to that designated commercially as white tagboard;

- Have a weight of at least 176 pounds (80 kg) per ream of 24 x 36 inches (610 mm x 910 mm), waterproofing materials included; and

- Be able to pass a 60 p.s.i. (414 kPa) Mullen test.

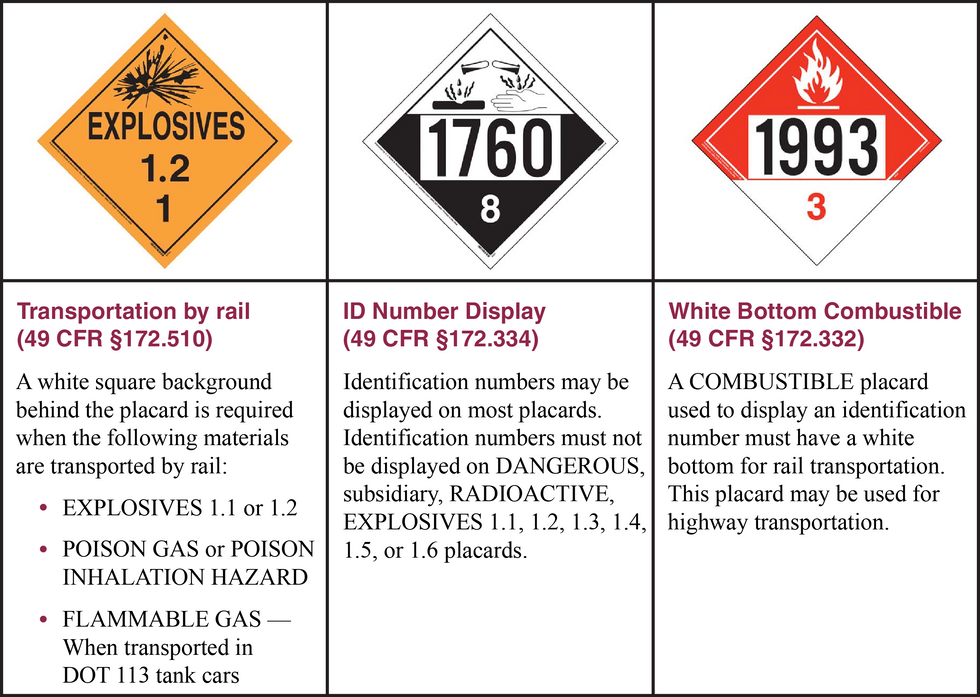

White square background

Transportation by highway (172.507)

A square background behind the placard is required when a motor vehicle is used to transport a highway route-controlled quantity of radioactive material.

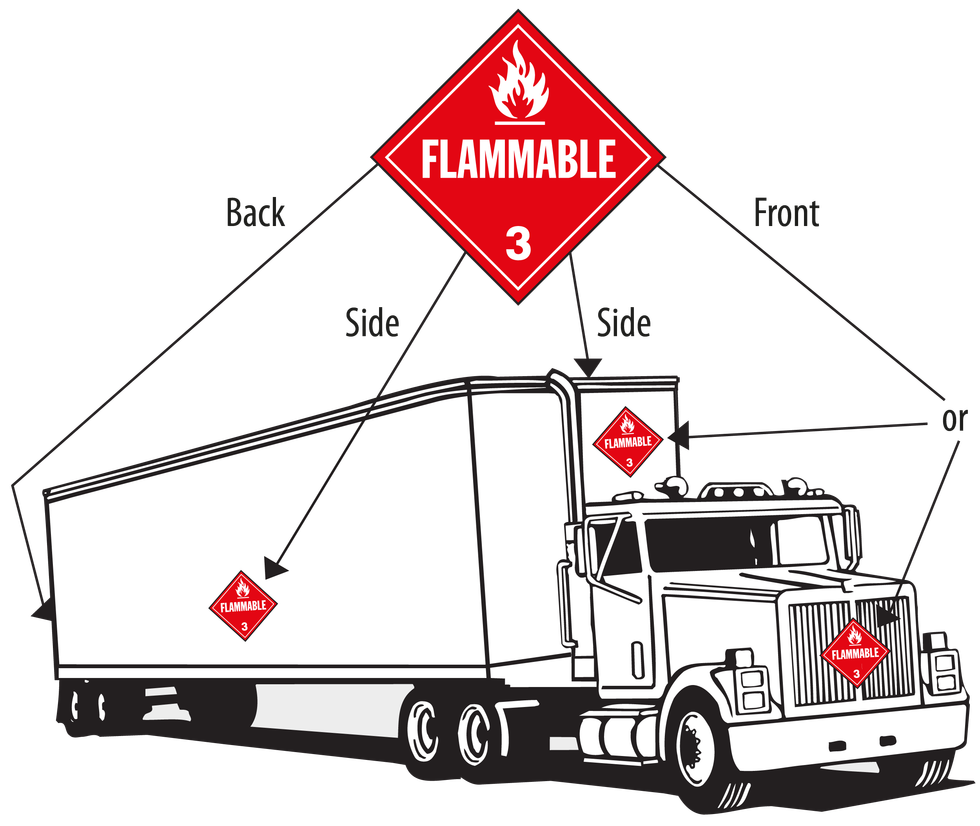

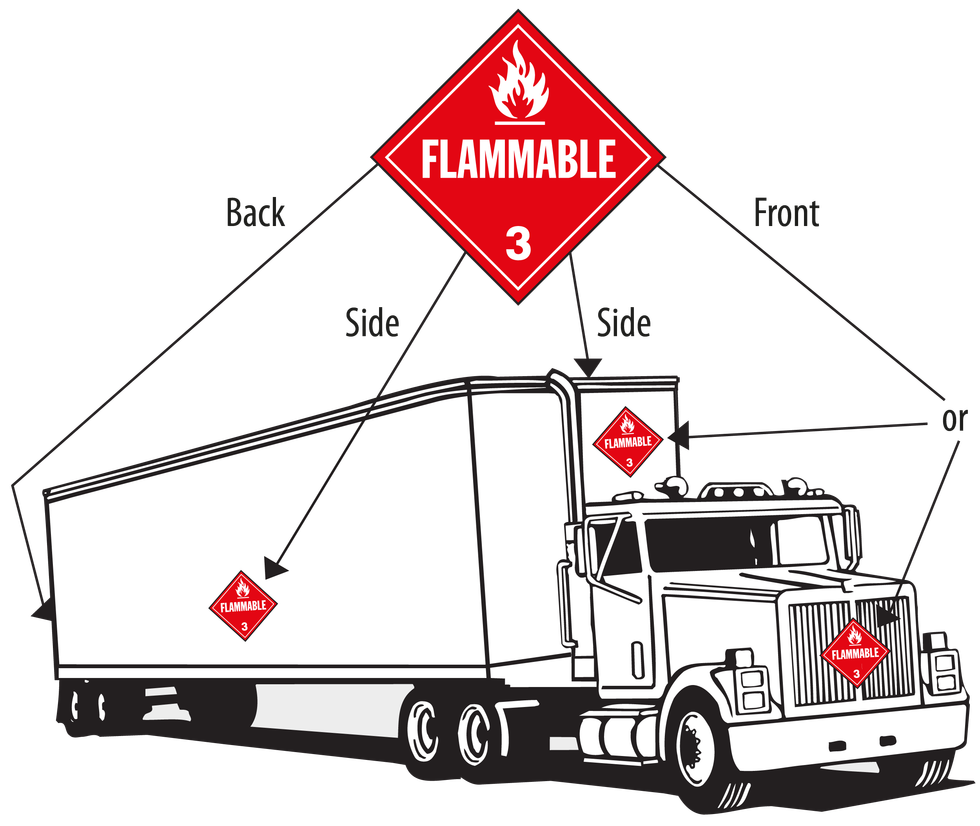

Where must placards be displayed?

- An affixed placard must be easily visible from the direction it is facing, unless the vehicle or railcar is coupled to another such unit.

- Bulk packagings, freight containers, and aircraft unit load devices have their own placarding requirements.

Placard placement (172.516)

Each placard affixed to a motor vehicle or railcar must be readily visible from the direction it faces — except from the direction of another vehicle or railcar to which the vehicle or railcar is coupled.

The placard placement for the front of a vehicle may be on the front of the truck-tractor instead of, or in addition to, the placard on the front of the cargo-carrying body (e.g., trailer or semitrailer).

Best practice

Most carriers place the front placard on the front of the tractor to make it easier for the driver to change or remove the placard if necessary.

Placards displayed on freight containers or portable tanks loaded on (not enclosed in) a motor vehicle or railcar may be used to meet placarding requirements for the motor vehicle or railcar.

In addition, each placard on a transport vehicle, bulk packaging, unit load device, or freight container must be:

- Located clear of any appurtenances and devices (e.g., ladders and pipes);

- Located away from any markings — such as advertising — that might substantially reduce its effectiveness, with a minimum distance of 3 inches (76 mm) required;

- Affixed to a background of contrasting color, or must have a dotted or solid line outer border that contrasts with the background color;

- Maintained by the carrier so its effectiveness will not be reduced in any way;

- Placed, as far as practicable, so dirt or water is not directed to it from the wheels of the vehicle;

- Attached, affixed, or placed securely in a placard holder; and

- Displayed with the word(s) or identification number (when authorized) shown horizontally, reading left to right.

Bulk packagings (172.514)

In most situations, a bulk packaging containing hazardous materials that requires placards must be placarded on each side and each end. Each bulk packaging that previously contained a hazardous material requiring placards must remain placarded when emptied unless it:

- Is sufficiently cleaned of residue and purged of vapors to remove any potential hazard,

- Is refilled with a material requiring different placards or no placards (provided that any residue remaining in the packaging is no longer hazardous), or

- Contains the residue of a hazardous substance in Class 9 in a quantity less than the reportable quantity and conforms to 173.29(b)(1).

The following bulk packagings may be placarded on only two opposite sides or may be labeled instead of placarded:

- A portable tank having a capacity of less than 1,000 gallons (3,785 L);

- A DOT 106 or 110 multi-unit tank car tank;

- A bulk packaging other than a portable tank, cargo tank, or tank car (such as a bulk bag or box) with a volumetric capacity of less than 640 cubic feet (18 cubic meters);

- An intermediate bulk container (IBC); and

- A large packaging.

Flexible bulk containers may be placarded in two opposing positions.

Freight containers and aircraft unit load devices (172.512)

A freight container or aircraft unit load device with a capacity less than 640 cubic feet (18 m3) is required to display one placard as specified in Section 172.504. This requirement does not apply if the freight container or unit load device:

- Is labeled according to Subpart E of the Hazardous Materials Regulations (HMR);

- Contains radioactive materials requiring the “RADIOACTIVE YELLOW III” label and is placarded with one “RADIOACTIVE” placard and labeled according to Subpart E; and

- Is identified as prepared according to Part 5, Chapter 2, Section 2.7 of the International Civil Aviation Organization (ICAO) Technical Instructions.

Freight containers with a capacity of less than 640 cubic feet that are not transported by air do not have to be placarded — they may be labeled instead.

Labels

- Regulations for labels contain requirements for design, use, placement, prohibitions, and exceptions.

Labels need to be printed on or affixed to non-bulk packages containing hazardous materials. They are designed to be color- and symbol-coded to provide easy and immediate warning of the hazardous materials inside the package. The Hazardous Materials Regulations (HMR) have specific requirements for design, use, placement, prohibitions, and exceptions for labels.

Labeling requirements apply primarily to non-bulk packagings. However, the following packages must also display labels if they are not placarded:

- Bulk packagings with a volumetric capacity of less than 640 cubic feet (18 cubic meters), other than cargo tanks, portable tanks, or tank cars;

- Portable tanks with less than 1,000 gallons (3,785 L) of capacity;

- DOT Specification 106 or 110 multi-unit tank car tanks; and

- Overpacks, freight containers, or unit load devices of less than 640 cubic feet (18 cubic meters) that contain a package for which labels are required.

Who is responsible for labeling, and what are the requirements?

Anyone offering or accepting a hazardous material for shipment must ensure the package is labeled according to the HMR requirements.

Once a material has been classified and a proper shipping name has been selected, determining the appropriate labels is a fairly easy process:

- Locate the selected proper shipping name in Column (2) of the Hazardous Materials Table (HMT).

- Refer to Column (6) of the HMT for the appropriate label code(s).

- The first label code listed indicates the material’s primary hazard. Any additional label codes indicate subsidiary hazards.

- Using the label codes from Column (6) in the HMT, find the name of the label(s) required to be on the package in the label substitution table in 172.101(g).

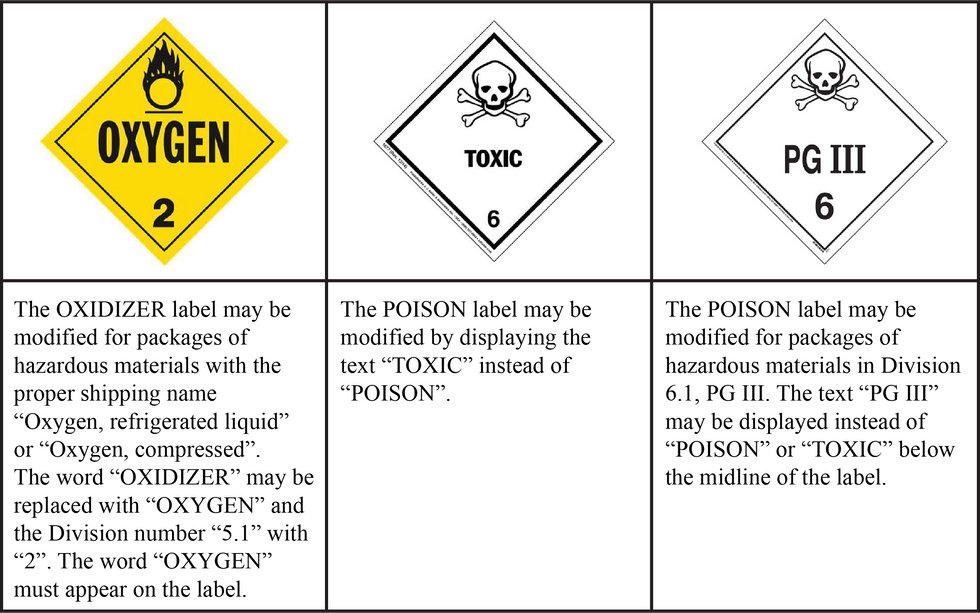

Except for the 6.1 label code, the label codes are the same as the hazard classes or divisions, and only one label is possible. For example, a 2.3 label code is a 2.3 (poison gas) label, a 3 label code is a Class 3 (flammable liquid) label, and a 5.1 label code is a 5.1 (oxidizer) label.

For the 6.1 label code, there are two possible labels. If the material has an inhalation hazard, Zone A or B, a “Poison Inhalation Hazard” label is required. If the material does not have an inhalation hazard, Zone A or B, a “Poison” label is required.

Each package containing a hazardous material must be labeled with the label(s) prescribed in Column (6) of the Hazardous Materials Table.

If the material has more than one hazard, all applicable subsidiary labels may not be listed in the table, such as generic or not otherwise specified (n.o.s.) shipping names. If this is the case, subsidiary labels must be determined according to 172.402.

A Division 6.1 subsidiary label is not required on a package containing a Class 8 material that has a subsidiary hazard of Division 6.1 if toxicity of the material is based solely on corrosive destruction of tissue rather than systemic poisoning. Also, a Division 4.1 subsidiary label is not required on a package bearing a Division 4.2 label.

Labeling exceptions and prohibited labels

- There are exceptions regarding labeling of certain non-bulk packages of hazardous materials.

- A label on a package that doesn’t contain the hazardous material shown on the label, or one that doesn’t represent the hazard of the packaged material, is prohibited.

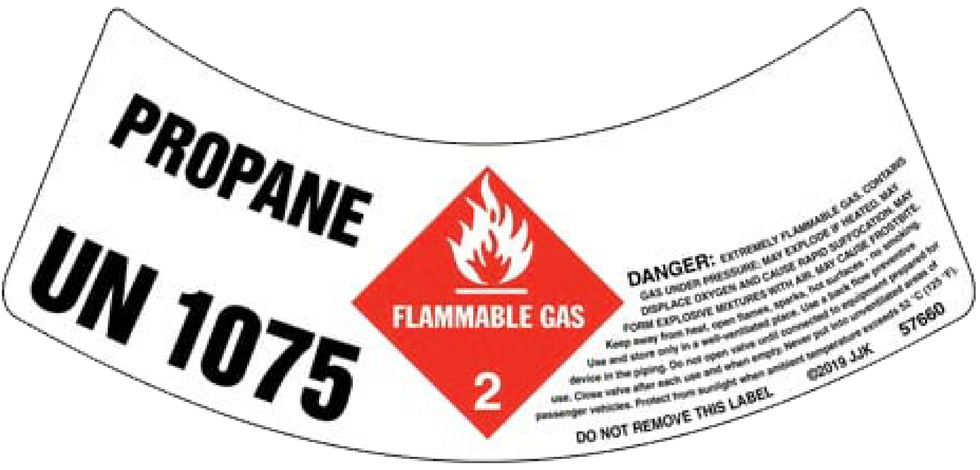

Exceptions (49 CFR 172.400a)

Not all non-bulk packages of hazardous materials will require labels. Labels are not required on the following:

- A cylinder or Dewar flask (173.320) containing Division 2.1, 2.2, or 2.3 gas that is not overpacked, and is durably and legibly marked in accordance with CGA C-7, Appendix A.

- A package or unit of military explosives — including ammunition — shipped by or on behalf of the U.S. Department of Defense (DOD) when:

- In freight containerload, carload or truckload shipments, if loaded and unloaded by the shipper or DOD; or

- In unitized or palletized break-bulk shipments by cargo vessel under charter to DOD, if at least one required label is displayed on each unitized or palletized load.

- A package of hazardous materials — other than ammunition — that is loaded and unloaded under the supervision of DOD personnel and is escorted by DOD personnel in a separate vehicle.

- A compressed gas cylinder that is permanently mounted in or on a transport vehicle.

- A freight container, aircraft unit load device, or portable tank that is placarded in accordance with the regulations or identified as provided in the International Civil Aviation Organization (ICAO) Technical Instructions.

- An overpack or unit load device in or on which labels that represent the hazard(s) inside are visible.

- A package of low-specific-activity radioactive material when being transported in a conveyance assigned for exclusive use of the consignor under Section 173.427(a)(6).

- Certain packages of small quantities and limited quantities, as provided in Part 173.

- A non-bulk package containing a combustible liquid.

Limited quantities

There are also exceptions to labeling for limited quantities in the following sections:

Prohibited labels

No package may display a hazardous material warning label unless the package contains the hazardous material and the label represents the hazard of the material in the package.

Packages may not be offered for transportation or transported with a marking or label that could be confused with or conflicts with the required labels unless the package is labeled in conformance with:

- The United Nations (UN) recommendations;

- The International Maritime Dangerous Goods (IMDG) Code;

- The ICAO’s Technical Instructions;

- Canada’s Transport Dangerous Goods (TDG) regulations; or

- The Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

Did you know?

Occupational Safety and Health Administration (OSHA) pictograms look similar to U.S. Department of Transportation (DOT) hazard warning labels. In fact, many pictograms and labels share the same images.

Label placement, duplicates, consolidated packages, specifications, and modifications

- Labels on packages of hazardous materials need to be easily visible with no markings or attachments blocking the labels from view.

- Duplicate labels and consolidated packages have their own requirements for compliance.

- Labels are required to meet certain specifications, though modifications and special labels are permitted in certain circumstances.

Placement

A label on a package of hazardous materials must be clearly visible and not obscured by markings or attachments. Each label must be printed on or affixed to a background of contrasting color, or must have a dotted or solid-line outer border.

The label must be printed on or affixed to a surface (other than the bottom) of the package containing the hazardous material. If possible, the label should be located on the same surface of the package and near the proper shipping name marking.

Also, a label may be printed on or placed on a securely affixed tag or may be affixed by other suitable means to:

- A package that contains no radioactive material and has dimensions less than those of the required label,

- A cylinder, or

- A package with such an irregular surface that a label cannot be satisfactorily affixed.

When primary and subsidiary labels are required, they must be displayed next to each other, within 6 inches (152.4 mm) of one another. Except as discussed in the section on using duplicate labels, duplicate labeling is not required on a package. This means that only one of each different required label would have to be on the package.

Using duplicate labels

Generally, only one of each different required label must be displayed on a package. However, duplicate labels must be displayed on at least two sides or two ends (other than the bottom) of the following:

- Each package or overpack having a volume of 64 cubic feet (1.8 cubic meters) or more;

- Each non-bulk package containing a radioactive material;

- Each DOT 106 or 110 multi-unit tank car tank, and labels must be displayed on each end;

- Each portable tank of less than 1,000 gallons (3,785 L) capacity;

- Each freight container or aircraft unit load device having a volume of 64 cubic feet (1.8 cubic meters) or more, but less than 640 cubic feet (18 cubic meters), and one of each required label must be displayed on or near the closure; and

- An IBC having a volume of 64 cubic feet (1.8 cubic meters) or more.

Labeling consolidated packages

When two or more packages containing compatible hazardous materials are placed within the same outside container or overpack, the outside container or overpack must be labeled for each class of material contained within the package, unless labels on the inside packages are visible and represent each hazardous material in the container or overpack.

Label specifications

Labels must meet the following specifications:

- Must be durable and weather-resistant. Must be able to withstand a 30-day exposure to conditions incident to transportation.

- Each side of a label must be a minimum size of 3.9 inches (100 mm). Each side must also have a solid-line inner border approximately 0.2 inches (5 mm) inside and parallel to the outside edge.

- The printing, inner border, and symbol on each label must be as shown in the Hazardous Materials Regulations (HMR).

- Specifications for color must be as prescribed in Appendix A to Part 172.

- The specified color must extend to the edge of the label (with a few exceptions), as prescribed for each label.

- The symbol, text, numbers, and border of a label must be black — except that white may be used on a label with a one-color background of green, red, or blue. White must be used for the text and class number for the “CORROSIVE” label.

- The hazard class or division number must be at least 0.25 inches (6.3 mm) and no greater than 0.5 inches (12.7 mm).

- When text is displayed, it must be in letters measuring at least 0.3 inches (7.6 mm) in height, with a few exceptions.

- Labels may contain form identification information — including the name of the maker — if such information is printed outside of the solid-line inner border in no larger than 10-point type.

Hazard class or division numbers must be displayed in the lower (bottom) corner of primary and subsidiary labels.

Label modifications

Text is not required on a primary or subsidiary label for Classes 1, 2, 3, 4, 5, 6, and 8. However, the label must meet the other specifications in the HMR.

Special labels (172.403, 172.407, 172.450)