Be Part of the Ultimate Safety & Compliance Community

Trending news, knowledge-building content, and more – all personalized to you!

You must calculate CO2 emissions according to paragraph (a) of this section, and calculate CH4 and N2O emissions according to paragraph (c) of this section.

(a) CO2emissions from fuel combustion. Calculate CO2 mass emissions by using one of the four calculation methodologies in paragraphs (a)(1) through (a)(4) of this section, subject to the applicable conditions, requirements, and restrictions set forth in paragraph (b) of this section. Alternatively, for units that meet the conditions of paragraph (a)(5) of this section, you may use CO2 mass emissions calculation methods from part 75 of this chapter, as described in paragraph (a)(5) of this section. For units that combust both biomass and fossil fuels, you must calculate and report CO2 emissions from the combustion of biomass separately using the methods in paragraph (e) of this section, except as otherwise provided in paragraphs (a)(5)(iv) and (e) of this section and in §98.36(d).

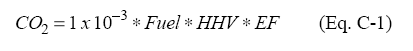

(1) Tier 1 Calculation Methodology. Calculate the annual CO2 mass emissions for each type of fuel by using Equation C-1, C-1a, or C-1b of this section (as applicable).

(i) Use Equation C-1 except when natural gas billing records are used to quantify fuel usage and gas consumption is expressed in units of therms or million Btu. In that case, use Equation C-1a or C-1b, as applicable.

Where:

CO2 = Annual CO2 mass emissions for the specific fuel type (metric tons).

Fuel = Mass or volume of fuel combusted per year, from company records as defined in §98.6 (express mass in short tons for solid fuel, volume in standard cubic feet for gaseous fuel, and volume in gallons for liquid fuel).

HHV = Default high heat value of the fuel, from Table C-1 of this subpart (mmBtu per mass or mmBtu per volume, as applicable).

EF = Fuel-specific default CO2 emission factor, from Table C-1 of this subpart (kg CO2/mmBtu).

1 x 10-3 = Conversion factor from kilograms to metric tons.

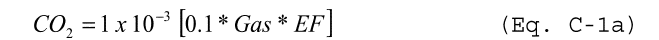

(ii) If natural gas consumption is obtained from billing records and fuel usage is expressed in therms, use Equation C-1a.

Where:

CO2 = Annual CO2 mass emissions from natural gas combustion (metric tons).

Gas = Annual natural gas usage, from billing records (therms).

EF = Fuel-specific default CO2 emission factor for natural gas, from Table C-1 of this subpart (kg CO2/mmBtu).

0.1 = Conversion factor from therms to mmBtu

1 x 10-3 = Conversion factor from kilograms to metric tons.

(iii) If natural gas consumption is obtained from billing records and fuel usage is expressed in mmBtu, use Equation C-1b.

Where:

CO2 = Annual CO2 mass emissions from natural gas combustion (metric tons).

Gas = Annual natural gas usage, from billing records (mmBtu).

EF = Fuel-specific default CO2 emission factor for natural gas, from Table C-1 of this subpart (kg CO2/mmBtu).

1 x 10-3 = Conversion factor from kilograms to metric tons.

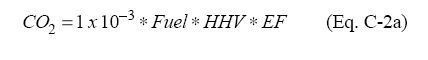

(2) Tier 2 Calculation Methodology. Calculate the annual CO2 mass emissions for each type of fuel by using either Equation C2a or C2c of this section, as appropriate.

(i) Equation C–2a of this section applies to any type of fuel listed in Table C–1 of the subpart, except for municipal solid waste (MSW). For MSW combustion, use Equation C–2c of this section.

Where:

CO2 = Annual CO2 mass emissions for a specific fuel type (metric tons).

Fuel = Mass or volume of the fuel combusted during the year, from company records as defined in §98.6 (express mass in short tons for solid fuel, volume in standard cubic feet for gaseous fuel, and volume in gallons for liquid fuel).

HHV = Annual average high heat value of the fuel (mmBtu per mass or volume). The average HHV shall be calculated according to the requirements of paragraph (a)(2)(ii) of this section.

EF = Fuel-specific default CO2 emission factor, from Table C–1 of this subpart (kg CO2/mmBtu).

1 × 10-3 = Conversion factor from kilograms to metric tons.

(ii) The minimum required sampling frequency for determining the annual average HHV (e.g., monthly, quarterly, semi-annually, or by lot) is specified in §98.34. The method for computing the annual average HHV is a function of unit size and how frequently you perform or receive from the fuel supplier the results of fuel sampling for HHV.

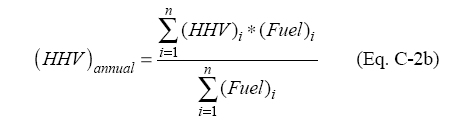

(A) If the results of fuel sampling are received monthly or more frequently, then for each unit with a maximum rated heat input capacity greater than or equal to 100 mmBtu/hr (or for a group of units that includes at least one unit of that size), the annual average HHV shall be calculated using Equation C-2b of this section.

Where:

(HHV)annual = Weighted annual average high heat value of the fuel (mmBtu per mass or volume).

(HHV)I = Measured high heat value of the fuel, for sample period “i” (which may be the arithmetic average of multiple determinations), or, if applicable, an appropriate substitute data value (mmBtu per mass or volume).

(Fuel)I = Mass or volume of the fuel combusted during the sample period “i,” (e.g., monthly, quarterly, semi-annually, or by lot) from company records (express mass in short tons for solid fuel, volume in standard cubic feet (e.g., for gaseous fuel, and volume in gallons for liquid fuel).

n = Number of sample periods in the year.

(B) If the results of fuel sampling are received less frequently than monthly, or, for a unit with a maximum rated heat input capacity less than 100 mmBtu/hr (or a group of such units) regardless of the HHV sampling frequency, the annual average HHV shall either be computed according to paragraph (a)(2)(ii)(A) of this section or as the arithmetic average HHV for all values for the year (including valid samples and substitute data values under §98.35).

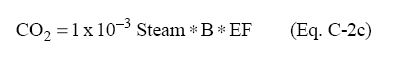

(iii) For units that combust municipal solid waste (MSW) and that produce steam, use Equation C–2c of this section. Equation C–2c of this section may also be used for any other solid fuel listed in Table C–1 of this subpart provided that steam is generated by the unit.

Where:

CO2 = Annual CO2 mass emissions from MSW or solid fuel combustion (metric tons).

Steam = Total mass of steam generated by MSW or solid fuel combustion during the reporting year (lb steam).

B = Ratio of the boiler’s maximum rated heat input capacity to its design rated steam output capacity (mmBtu/lb steam).

EF = Fuel-specific default CO2 emission factor, from Table C–1 of this subpart (kg CO2/mmBtu).

1 × 10-3 = Conversion factor from kilograms to metric tons.

(3) Tier 3 Calculation Methodology. Calculate the annual CO2 mass emissions for each fuel by using either Equation C3, C4, or C5 of this section, as appropriate.

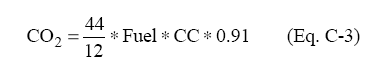

(i) For a solid fuel, use Equation C–3 of this section.

Where:

CO2 = Annual CO2 mass emissions from the combustion of the specific solid fuel (metric tons).

Fuel = Annual mass of the solid fuel combusted, from company records as defined in §98.6 (short tons).

CC = Annual average carbon content of the solid fuel (percent by weight, expressed as a decimal fraction, e.g., 95% = 0.95). The annual average carbon content shall be determined using the same procedures as specified for HHV in paragraph (a)(2)(ii) of this section.

44/12 = Ratio of molecular weights, CO2 to carbon.

0.91 = Conversion factor from short tons to metric tons.

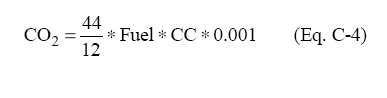

(ii) For a liquid fuel, use Equation C–4 of this section.

Where:

CO2 = Annual CO2 mass emissions from the combustion of the specific liquid fuel (metric tons).

Fuel = Annual volume of the liquid fuel combusted (gallons). The volume of fuel combusted must be measured directly, using fuel flow meters calibrated according to §98.3(i). Fuel billing meters may be used for this purpose. Tank drop measurements may also be used.

CC = Annual average carbon content of the liquid fuel (kg C per gallon of fuel). The annual average carbon content shall be determined using the same procedures as specified for HHV in paragraph (a)(2)(ii) of this section.

44/12 = Ratio of molecular weights, CO2 to carbon.

0.001 = Conversion factor from kg to metric tons.

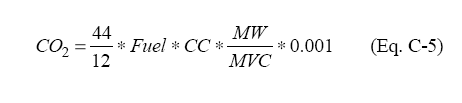

(iii) For a gaseous fuel, use Equation C–5 of this section.

Where:

CO2 = Annual CO2 mass emissions from combustion of the specific gaseous fuel (metric tons).

Fuel = Annual volume of the gaseous fuel combusted (scf). The volume of fuel combusted must be measured directly, using fuel flow meters calibrated according to §98.3(i). Fuel billing meters may be used for this purpose.

CC = Annual average carbon content of the gaseous fuel (kg C per kg of fuel). The annual average carbon content shall be determined using the same procedures as specified for HHV in paragraph (a)(2)(ii) of this section.

MW = Annual average molecular weight of the gaseous fuel (kg/kg-mole). The annual average molecular weight shall be determined using the same procedures as specified for HHV in paragraph (a)(2)(ii) of this section.

MVC =Molar volume conversion factor at standard conditions, as defined in §98.6. Use 849.5 scf per kg mole if you select 68ºF as standard temperature and 836.6 scf per kg mole if you select 60ºF as standard temperature.

44/12 = Ratio of molecular weights, CO2 to carbon.

(iv) Fuel flow meters that measure mass flow rates may be used for liquid or gaseous fuels, provided that the fuel density is used to convert the readings to volumetric flow rates. The density shall be measured at the same frequency as the carbon content. You must measure the density using one of the following appropriate methods. You may use a method published by a consensus-based standards organization, if such a method exists, or you may use industry standard practice. Consensus-based standards organizations include, but are not limited to, the following: ASTM International (100 Barr Harbor Drive, P.O. Box CB700, West Conshohocken, Pennsylvania 19428-B2959, (800) 262-1373, http://www.astm.org), the American National Standards Institute (ANSI, 1819 L Street, NW., 6th floor, Washington, DC 20036, (202) 293-8020, http://www.ansi.org), the American Gas Association (AGA), 400 North Capitol Street, NW., 4th Floor, Washington, DC 20001, (202) 824-7000, http://www.aga.org), the American Society of Mechanical Engineers (ASME, Three Park Avenue, New York, NY 10016-5990, (800) 843-2763, http://www.asme.org), the American Petroleum Institute (API, 1220 L Street, NW., Washington, DC 20005-4070, (202) 682-8000, http://www.api.org), and the North American Energy Standards Board (NAESB, 801 Travis Street, Suite 1675, Houston, TX 77002,(713) 356-0060, http://www.api.org). The method(s) used shall be documented in the GHG Monitoring Plan required under §98.3(g)(5).

(v) The following default density values may be used for fuel oil, in lieu of using the methods in paragraph (a)(3)(iv) of this section: 6.8 lb/gal for No. 1 oil; 7.2 lb/gal for No. 2 oil; 8.1 lb/gal for No. 6 oil.

0.001 = Conversion factor from kg to metric tons.

(4) Tier 4 Calculation Methodology. Calculate the annual CO2 mass emissions from all fuels combusted in a unit, by using quality-assured data from continuous emission monitoring systems (CEMS).

(i) This methodology requires a CO2 concentration monitor and a stack gas volumetric flow rate monitor, except as otherwise provided in paragraph (a)(4)(iv) of this section. Hourly measurements of CO2 concentration and stack gas flow rate are converted to CO2 mass emission rates in metric tons per hour.

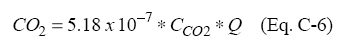

(ii) When the CO2 concentration is measured on a wet basis, Equation C–6 of this section is used to calculate the hourly CO2 emission rates:

Where:

CO2 = CO2 mass emission rate (metric tons/hr).

CCO2 = Hourly average CO2 concentration (% CO2).

Q = Hourly average stack gas volumetric flow rate (scfh).

5.18 × 10-7 = Conversion factor (metric tons/scf/% CO2).

(iii) If the CO2 concentration is measured on a dry basis, a correction for the stack gas moisture content is required. You shall either continuously monitor the stack gas moisture content using a method described in §75.11(b)(2) of this chapter or use an appropriate default moisture percentage. For coal, wood, and natural gas combustion, you may use the default moisture values specified in §75.11(b)(1) of this chapter. Alternatively, for any type of fuel, you may determine an appropriate site-specific default moisture value (or values), using measurements made with EPA Method 4--Determination Of Moisture Content In Stack Gases, in appendix A-3 to part 60 of this chapter. Moisture data from the relative accuracy test audit (RATA) of a CEMS may be used for this purpose. If this option is selected, the site-specific moisture default value(s) must represent the fuel(s) or fuel blends that are combusted in the unit during normal, stable operation, and must account for any distinct difference(s) in the stack gas moisture content associated with different process operating conditions. For each site-specific default moisture percentage, at least nine Method 4 runs are required, except where the option to use moisture data from a RATA is selected, and the applicable regulation allows a single moisture determination to represent two or more RATA runs. In that case, you may base the site-specific moisture percentage on the number of moisture runs allowed by the RATA regulation. Calculate each site-specific default moisture value by taking the arithmetic average of the Method 4 runs. Each site-specific moisture default value shall be updated whenever the owner or operator believes the current value is non-representative, due to changes in unit or process operation, but in any event no less frequently than annually. Use the updated moisture value in the subsequent CO2 emissions calculations. For each unit operating hour, a moisture correction must be applied to Equation C-6 of this section as follows:

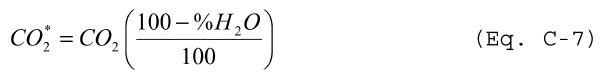

Where:

CO2* = Hourly CO2 mass emission rate, corrected for moisture (metric tons/hr).

CO2 = Hourly CO2 mass emission rate from Equation C-6 of this section, uncorrected (metric tons/hr).

%H2O = Hourly moisture percentage in the stack gas (measured or default value, as appropriate).

(iv) An oxygen (O2) concentration monitor may be used in lieu of a CO2 concentration monitor to determine the hourly CO2 concentrations, in accordance with Equation F-14a or F-14b (as applicable) in appendix F to part 75 of this chapter, if the effluent gas stream monitored by the CEMS consists solely of combustion products (i.e., no process CO2 emissions or CO2 emissions from sorbent are mixed with the combustion products) and if only fuels that are listed in Table 1 in section 3.3.5 of appendix F to part 75 of this chapter are combusted in the unit. If the O2 monitoring option is selected, the F-factors used in Equations F-14a and F-14b shall be determined according to section 3.3.5 or section 3.3.6 of appendix F to part 75 of this chapter, as applicable. If Equation F-14b is used, the hourly moisture percentage in the stack gas shall be determined in accordance with paragraph (a)(4)(iii) of this section.

(v) Each hourly CO2 mass emission rate from Equation C–6 or C–7 of this section is multiplied by the operating time to convert it from metric tons per hour to metric tons. The operating time is the fraction of the hour during which fuel is combusted (e.g., the unit operating time is 1.0 if the unit operates for the whole hour and is 0.5 if the unit operates for 30 minutes in the hour). For common stack configurations, the operating time is the fraction of the hour during which effluent gases flow through the common stack.

(vi) The hourly CO2 mass emissions are then summed over each calendar quarter and the quarterly totals are summed to determine the annual CO2 mass emissions.

(vii) If both biomass and fossil fuel are combusted during the year, determine and report the biogenic CO2 mass emissions separately, as described in paragraph (e) of this section.

(viii) If a portion of the flue gases generated by a unit subject to Tier 4 (e.g., a slip stream) is continuously diverted from the main flue gas exhaust system for the purpose of heat recovery or some other similar process, and then exhausts through a stack that is not equipped with the continuous emission monitors to measure CO2 mass emissions, CO2 emissions shall be determined as follows:

(A) At least once a year, use EPA Methods 2 and 3A, and (if necessary) Method 4 in appendices A-2 and A-3 to part 60 of this chapter to perform emissions testing at a set point that best represents normal, stable process operating conditions. A minimum of three one-hour Method 3A tests are required, to determine the CO2 concentration. A Method 2 test shall be performed during each Method 3A run, to determine the stack gas volumetric flow rate. If moisture correction is necessary, a Method 4 run shall also be performed during each Method 3A run. Important parametric information related to the stack gas flow rate (e.g., damper positions, fan settings, etc.) shall also be recorded during the test.

(B) Calculate a CO2 mass emission rate (in metric tons/hr) from the stack test data, using a version of Equation C-6 in paragraph (a)(4)(ii) of this section, modified as follows. In the Equation C-6 nomenclature, replace the words “Hourly average” in the definitions of “CCO2 ” and “Q” with the words “3-run average”. Substitute the arithmetic average values of CO2 concentration and stack gas flow rate from the emission testing into modified Equation C-6. If CO2 is measured on a dry basis, a moisture correction of the calculated CO2 mass emission rate is required. Use Equation C-7 in paragraph (a)(4)(ii) of this section to make this correction; replace the word “Hourly” with the words “3-run average” in the equation nomenclature.

(C) The results of each annual stack test shall be used in the GHG emissions calculations for the year of the test.

(D) If, for the majority of the operating hours during the year, the diverted stream is withdrawn at a steady rate at or near the tested set point (as evidenced by fan and damper settings and/or other parameters), you may use the calculated CO2 mass emission rate from paragraph (a)(4)(viii)(B) of this section to estimate the CO2 mass emissions for all operating hours in which flue gas is diverted from the main exhaust system. Otherwise, you must account for the variation in the flow rate of the diverted stream, as described in paragraph (c)(4)(viii)(E) of this section.

(E) If the flow rate of the diverted stream varies significantly throughout the year, except as provided below, repeat the stack test and emission rate calculation procedures described in paragraphs (c)(4)(viii)(A) and (c)(4)(viii)(B) of this section at a minimum of two more set points across the range of typical operating conditions to develop a correlation between CO2 mass emission rate and the parametric data. If additional testing is not feasible, use the following approach to develop the necessary correlation. Assume that the average CO2 concentration obtained in the annual stack test is the same at all operating set points. Then, beginning with the measured flow rate from the stack test and the associated parametric data, perform an engineering analysis to estimate the stack gas flow rate at two or more additional set points. Calculate the CO2 mass emission rate at each set point.

(F) Calculate the annual CO2 mass emissions for the diverted stream as follows. For a steady-state process, multiply the number of hours in which flue gas was diverted from the main exhaust system by the CO2 mass emission rate from the stack test. Otherwise, using the best available information and engineering judgment, apply the most representative CO2 mass emission rate from the correlation in paragraph (c)(4)(viii)(E) of this section to determine the CO2 mass emissions for each hour in which flue gas was diverted, and sum the results. To simplify the calculations, you may count partial operating hours as full hours.

(G) Finally, add the CO2 mass emissions from paragraph(c)(4)(viii)(F) of this section to the annual CO2 mass emissions measured by the CEMS at the main stack. Report this sum as the total annual CO2 mass emissions for the unit.

(H) The exact method and procedures used to estimate the CO2 mass emissions for the diverted portion of the flue gas exhaust stream shall be documented in the Monitoring Plan required under §98.3(g)(5).

(5) Alternative methods for certain units subject to Part 75 of this chapter. Certain units that are not subject to subpart D of this part and that report data to EPA according to Part 75 of this chapter may qualify to use the alternative methods in this paragraph (a)(5), in lieu of using any of the four calculation methodology tiers.

(i) For a unit that combusts only natural gas and/or fuel oil, is not subject to subpart D of this part, monitors and reports heat input data year-round according to appendix D to Part 75 of this chapter, but is not required by the applicable Part 75 program to report CO2 mass emissions data, calculate the annual CO2 mass emissions for the purposes of this part as follows:

(A) Use the hourly heat input data from appendix D to Part 75 of this chapter, together with Equation G-4 in appendix G to Part 75 of this chapter to determine the hourly CO2 mass emission rates, in units of tons/hr;

(B) Use Equations F-12 and F-13 in appendix F to Part 75 of this chapter to calculate the quarterly and cumulative annual CO2 mass emissions, respectively, in units of short tons; and

(C) Divide the cumulative annual CO2 mass emissions value by 1.1023 to convert it to metric tons.

(ii) For a unit that combusts only natural gas and/or fuel oil, is not subject to subpart D of this part, monitors and reports heat input data year-round according to §75.19 of this chapter but is not required by the applicable part 75 program to report CO2 mass emissions data, calculate the annual CO2 mass emissions for the purposes of this part as follows:

(A) Calculate the hourly CO2 mass emissions, in units of short tons, using Equation LM-11 in §75.19(c)(4)(iii) of this chapter.

(B) Sum the hourly CO2 mass emissions values over the entire reporting year to obtain the cumulative annual CO2 mass emissions, in units of short tons.

(C) Divide the cumulative annual CO2 mass emissions value by 1.1023 to convert it to metric tons.

(iii) For a unit that is not subject to subpart D of this part, uses flow rate and CO2 (or O2) CEMS to report heat input data year-round according to part 75 of this chapter, but is not required by the applicable part 75 program to report CO2 mass emissions data, calculate the annual CO2 mass emissions as follows:

(A) Use Equation F-11 or F-2 (as applicable) in appendix F to part 75 of this chapter to calculate the hourly CO2 mass emission rates from the CEMS data. If an O2 monitor is used, convert the hourly average O2 readings to CO2 using Equation F-14a or F-14b in appendix F to part 75 of this chapter (as applicable), before applying Equation F-11 or F-2.

(B) Use Equations F-12 and F-13 in appendix F to part 75 of this chapter to calculate the quarterly and cumulative annual CO2 mass emissions, respectively, in units of short tons.

(C) Divide the cumulative annual CO2 mass emissions value by 1.1023 to convert it to metric tons.

(iv) For units that qualify to use the alternative CO2 emissions calculation methods in paragraphs (a)(5)(i) through (a)(5)(iii) of this section, if both biomass and fossil fuel are combusted during the year, separate calculation and reporting of the biogenic CO2 mass emissions (as described in paragraph (e) of this section) is optional, only for the 2010 reporting year, as provided in §98.3(c)(12).

(b) Use of the four tiers. Use of the four tiers of CO2 emissions calculation methodologies described in paragraph (a) of this section is subject to the following conditions, requirements, and restrictions:

(1) The Tier 1 Calculation Methodology:

(i) May be used for any fuel listed in Table C–1 of this subpart that is combusted in a unit with a maximum rated heat input capacity of 250 mmBtu/hr or less.

(ii) May be used for MSW in a unit of any size that does not produce steam, if the use of Tier 4 is not required.

(iii) May be used for solid, gaseous, or liquid biomass fuels in a unit of any size provided that the fuel is listed in Table C–1 of this subpart.

(iv) May not be used if you routinely perform fuel sampling and analysis for the fuel high heat value (HHV) or routinely receive the results of HHV sampling and analysis from the fuel supplier at the minimum frequency specified in §98.34(a), or at a greater frequency. In such cases, Tier 2 shall be used. This restriction does not apply to paragraphs (b)(1)(ii), (b)(1)(v), (b)(1)(vi), and (b)(1)(vii) of this section.

(v) May be used for natural gas combustion in a unit of any size, in cases where the annual natural gas consumption is obtained from fuel billing records in units of therms or mmBtu.

(vi) May be used for MSW combustion in a small, batch incinerator that burns no more than 1,000 tons per year of MSW.

(vii) May be used for the combustion of MSW and/or tires in a unit, provided that no more than 10 percent of the unit’s annual heat input is derived from those fuels, combined. Notwithstanding this requirement, if a unit combusts both MSW and tires and the reporter elects not to separately calculate and report biogenic CO2 emissions from the combustion of tires, Tier 1 may be used for the MSW combustion, provided that no more than 10 percent of the unit’s annual heat input is derived from MSW.

(viii) May be used for the combustion of a fuel listed in Table C-1 if the fuel is combusted in a unit with a maximum rated heat input capacity greater than 250 mmBtu/hr (or, pursuant to §98.36(c)(3), in a group of units served by a common supply pipe, having at least one unit with a maximum rated heat input capacity greater than 250 mmBtu/hr), provided that both of the following conditions apply:

(A) The use of Tier 4 is not required.

(B) The fuel provides less than 10 percent of the annual heat input to the unit, or if §98.36(c)(3) applies, to the group of units served by a common supply pipe.

(2) The Tier 2 Calculation Methodology:

(i) May be used for the combustion of any type of fuel in a unit with a maximum rated heat input capacity of 250 mmBtu/hr or less provided that the fuel is listed in Table C–1 of this subpart.

(ii) May be used in a unit with a maximum rated heat input capacity greater than 250 mmBtu/hr for the combustion of natural gas and/or distillate fuel oil.

(iii) May be used for MSW in a unit of any size that produces steam, if the use of Tier 4 is not required.

(3) The Tier 3 Calculation Methodology:

(i) May be used for a unit of any size that combusts any type of fuel listed in Table C–1 of this subpart (except for MSW), unless the use of Tier 4 is required.

(ii) Shall be used for a unit with a maximum rated heat input capacity greater than 250 mmBtu/hr that combusts any type of fuel listed in Table C–1 of this subpart (except MSW), unless either of the following conditions apply:

(A) The use of Tier 1 or 2 is permitted, as described in paragraphs (b)(1)(iii), (b)(1)(v), (b)(1)(viii), and (b)(2)(ii) of this section.

(B) The use of Tier 4 is required.

(iii) Shall be used for a fuel not listed in Table C–1 of this subpart if the fuel is combusted in a unit with a maximum rated heat input capacity greater than 250 mmBtu/hr provided that both of the following conditions apply:

(A) The use of Tier 4 is not required.

(B) The fuel provides 10% or more of the annual heat input to the unit or, if §98.36(c)(3) applies, to a group of units served by common supply pipe.

(4) The Tier 4 Calculation Methodology:

(i) Tier 4 may also be used for any group of stationary fuel combustion units, process units, or manufacturing units that share a common stack or duct.

(ii) Shall be used if the unit meets all six of the conditions specified in paragraphs (b)(4)(ii)(A) through (b)(4)(ii)(F) of this section:

(A) The unit has a maximum rated heat input capacity greater than 250 mmBtu/hr, or if the unit combusts municipal solid waste and has a maximum rated input capacity greater than 600 tons per day of MSW.

(B) The unit combusts solid fossil fuel or MSW as the primary fuel.

(C) The unit has operated for more than 1,000 hours in any calendar year since 2005.

(D) The unit has installed CEMS that are required either by an applicable Federal or State regulation or the unit’s operating permit.

(E) The installed CEMS include a gas monitor of any kind or a stack gas volumetric flow rate monitor, or both and the monitors have been certified, either in accordance with the requirements of part 75 of this chapter, part 60 of this chapter, or an applicable State continuous monitoring program.

(F) The installed gas or stack gas volumetric flow rate monitors are required, either by an applicable Federal or State regulation or by the unit’s operating permit, to undergo periodic quality assurance testing in accordance with either appendix B to part 75 of this chapter, appendix F to part 60 of this chapter, or an applicable State continuous monitoring program.

(iii) Shall be used for a unit with a maximum rated heat input capacity of 250 mmBtu/hr or less and for a unit that combusts municipal solid waste with a maximum rated input capacity of 600 tons of MSW per day or less, if the unit meets all of the following three conditions:

(A) The unit has both a stack gas volumetric flow rate monitor and a CO2 concentration monitor.

(B) The unit meets the conditions specified in paragraphs (b)(4)(ii)(B) through (b)(4)(ii)(D) of this section.

(C) The CO2 and stack gas volumetric flow rate monitors meet the conditions specified in paragraphs (b)(4)(ii)(E) and (b)(4)(ii)(F) of this section.

(iv) May apply to common stack or duct configurations where:

(A) The combined effluent gas streams from two or more stationary fuel combustion units are vented through a monitored common stack or duct. In this case, Tier 4 shall be used if all of the conditions in paragraph (b)(4)(iv)(A)(1) of this section or if the conditions in paragraph (b)(4)(iv)(A)(2) of this section are met.

(1) At least one of the units meets the requirements of paragraphs (b)(4)(ii)(A) through (b)(4)(ii)(C) of this section, and the CEMS installed at the common stack (or duct) meet the requirements of paragraphs (b)(4)(ii)(D) through (b)(4)(ii)(F) of this section.

(2) At least one of the units and the monitors installed at the common stack or duct meet the requirements of paragraph (b)(4)(iii) of this section.

(B) The combined effluent gas streams from a process or manufacturing unit and a stationary fuel combustion unit are vented through a monitored common stack or duct. In this case, Tier 4 shall be used if the combustion unit and the monitors installed at the common stack or duct meet the applicability criteria specified in paragraph (b)(4)(iv)(A)(1), or (b)(4)(iv)(A)(2) of this section.

(C) The combined effluent gas streams from two or more manufacturing or process units are vented through a common stack or duct. In this case, if any of the units is required by an applicable subpart of this part to use Tier 4, the CO2 mass emissions may be monitored at each individual unit, or the combined CO2 mass emissions may be monitored at the common stack or duct. However, if it is not feasible to monitor the individual units, the combined CO2 mass emissions shall be monitored at the common stack or duct.

(5) The Tier 4 Calculation Methodology shall be used:

(i) Starting on January 1, 2010, for a unit that is required to report CO2 mass emissions beginning on that date, if all of the monitors needed to measure CO2 mass emissions have been installed and certified by that date.

(ii) No later than January 1, 2011, for a unit that is required to report CO2 mass emissions beginning on January 1, 2010, if all of the monitors needed to measure CO2 mass emissions have not been installed and certified by January 1, 2010. In this case, you may use Tier 2 or Tier 3 to report GHG emissions for 2010. However, if the required CEMS are certified some time in 2010, you need not wait until January 1, 2011 to begin using Tier 4. Rather, you may switch from Tier 2 or Tier 3 to Tier 4 as soon as CEMS certification testing is successfully completed. If this reporting option is chosen, you must document the change in CO2 calculation methodology in the Monitoring Plan required under §98.3(g)(5) and in the GHG emissions report under §98.3(c). Data recorded by the CEMS during a certification test period in 2010 may be used for reporting under this part, provided that the following two conditions are met:

(A) The certification tests are passed in sequence, with no test failures.

(B) No unscheduled maintenance or repair of the CEMS is performed during the certification test period.

(iii) No later than 180 days following the date on which a change is made that triggers Tier 4 applicability under paragraph (b)(4)(ii) or (b)(4)(iii) of this section (e.g., a change in the primary fuel, manner of unit operation, or installed continuous monitoring equipment).

(6) You may elect to use any applicable higher tier for one or more of the fuels combusted in a unit. For example, if a 100 mmBtu/hr unit combusts natural gas and distillate fuel oil, you may elect to use Tier 1 for natural gas and Tier 3 for the fuel oil, even though Tier 1 could have been used for both fuels. However, for units that use either the Tier 4 or the alternative calculation methodology specified in paragraph (a)(5)(iii) of this section, CO2 emissions from the combustion of all fuels shall be based solely on CEMS measurements.

(c) Calculation of CH4 and N2O emissions from stationary combustion sources. You must calculate annual CH4 and N2O mass emissions only for units that are required to report CO2 emissions using the calculation methodologies of this subpart and for only those fuels that are listed in Table C–2 of this subpart.

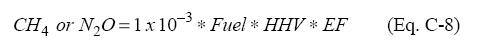

(1) Use Equation C-8 of this section to estimate CH4 and N2O emissions for any fuels for which you use the Tier 1 or Tier 3 calculation methodologies for CO2, except when natural gas usage in units of therms or mmBtu is obtained from gas billing records. In that case, use Equation C-8a in paragraph (c)(1)(i) of this section or Equation C-8b in paragraph (c)(1)(ii) of this section (as applicable). For Equation C-8, use the same values for fuel consumption that you use for the Tier 1 or Tier 3 calculation.

Where:

CH4 or N2O = Annual CH4 or N2O emissions from the combustion of a particular type of fuel (metric tons).

Fuel = Mass or volume of the fuel combusted, either from company records or directly measured by a fuel flow meter, as applicable (mass or volume per year).

HHV = Default high heat value of the fuel from Table C-1 of this subpart; alternatively, for Tier 3, if actual HHV data are available for the reporting year, you may average these data using the procedures specified in paragraph (a)(2)(ii) of this section, and use the average value in Equation C-8 (mmBtu per mass or volume).

EF = Fuel-specific default emission factor for CH4 or N2O, from Table C–2 of this subpart (kg CH4 or N2O per mmBtu).

1 × 10-3 = Conversion factor from kilograms to metric tons.

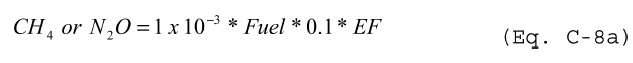

(i) Use Equation C-8a to calculate CH4 and N2O emissions when natural gas usage is obtained from gas billing records in units of therms.

Where:

CH4 or N2O = Annual CH4 or N2O emissions from the combustion of natural gas (metric tons).

Fuel = Annual natural gas usage, from gas billing records (therms).

EF = Fuel-specific default emission factor for CH4 or N2O, from Table C-2 of this subpart (kg CH4 or N2O per mmBtu).

0.1 = Conversion factor from therms to mmBtu

1 x 10-3 = Conversion factor from kilograms to metric tons.

(ii) Use Equation C-8b to calculate CH4 and N2O emissions when natural gas usage is obtained from gas billing records in units of mmBtu.

CH4 or N2O = 1 x 10-3 * Fuel * EF (Eq. C-8b)

Where:

CH4 or N2O = Annual CH4 or N2O emissions from the combustion of natural gas (metric tons).

Fuel = Annual natural gas usage, from gas billing records (mmBtu).

EF = Fuel-specific default emission factor for CH4 or N2O, from Table C-2 of this subpart (kg CH4 or N2O per mmBtu).

1 x 10-3 = Conversion factor from kilograms to metric tons.

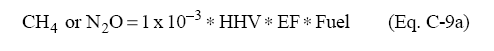

(2) Use Equation C-9a of this section to estimate CH4 and N2O emissions for any fuels for which you use the Tier 2 Equation C-2a of this section to estimate CO2 emissions. Use the same values for fuel consumption and HHV that you use for the Tier 2 calculation.

Where:

CH4 or N2O = Annual CH4 or N2O emissions from the combustion of a particular type of fuel (metric tons).

Fuel = Mass or volume of the fuel combusted during the reporting year.

HHV = High heat value of the fuel, averaged for all valid measurements for the reporting year (mmBtu per mass or volume).

EF = Fuel-specific default emission factor for CH4 or N2O, from Table C–2 of this subpart (kg CH4 or N2O per mmBtu).

1 × 10-3 = Conversion factor from kilograms to metric tons.

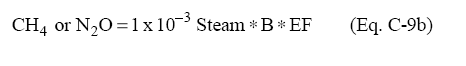

(3) Use Equation C–9b of this section to estimate CH4 and N2O emissions for any fuels for which you use Equation C–2c of this section to calculate the CO2 emissions. Use the same values for steam generation and the ratio “B” that you use for Equation C–2c.

Where:

CH4 or N2O = Annual CH4 or N2O emissions from the combustion of a solid fuel (metric tons).

Steam = Total mass of steam generated by solid fuel combustion during the reporting year (lb steam).

B = Ratio of the boiler’s maximum rated heat input capacity to its design rated steam output (mmBtu/lb steam).

EF = Fuel-specific emission factor for CH4 or N2O, from Table C–2 of this subpart (kg CH4 or N2O per mmBtu).

1 × 10-3 = Conversion factor from kilograms to metric tons.

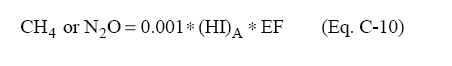

(4) Use Equation C-10 of this section for: units subject to subpart D of this part; units that qualify for and elect to use the alternative CO2 mass emissions calculation methodologies described in paragraph (a)(5) of this section; and units that use the Tier 4 Calculation Methodology.

Where:

CH4 or N2O = Annual CH4 or N2O emissions from the combustion of a particular type of fuel (metric tons).

(HI)A = Cumulative annual heat input from combustion of the fuel (mmBtu).

EF = Fuel-specific emission factor for CH4 or N2O, from Table C–2 of this section (kg CH4 or N2O per mmBtu).

0.001 = Conversion factor from kg to metric tons.

(i) If only one type of fuel listed in Table C-2 of this subpart is combusted during the reporting year, substitute the cumulative annual heat input from combustion of the fuel into Equation C-10 of this section to calculate the annual CH4 or N2O emissions. For units in the Acid Rain Program and units that report heat input data to EPA year-round according to part 75 of this chapter, obtain the cumulative annual heat input directly from the electronic data reports required under §75.64 of this chapter. For Tier 4 units, use the best available information, as described in paragraph (c)(4)(ii)(C) of this section, to estimate the cumulative annual heat input (HI)A.

(ii) If more than one type of fuel listed in Table C-2 of this subpart is combusted during the reporting year, use Equation C-10 of this section separately for each type of fuel, except as provided in paragraph (c)(4)(ii)(B) of this section. Determine the appropriate values of (HI)A as follows:

(A) For units in the Acid Rain Program and other units that report heat input data to EPA year-round according to part 75 of this chapter, obtain (HI)A for each type of fuel from the electronic data reports required under §75.64 of this chapter, except as otherwise provided in paragraphs (c)(4)(ii)(B) and (c)(4)(ii)(D) of this section.

(B) For a unit that uses CEMS to monitor hourly heat input according to part 75 of this chapter, the value of (HI)A obtained from the electronic data reports under §75.64 of this chapter may be attributed exclusively to the fuel with the highest F-factor, when the reporting option in 3.3.6.5 of appendix F to part 75 of this chapter is selected and implemented.

(C) For Tier 4 units, use the best available information (e.g., fuel feed rate measurements, fuel heating values, engineering analysis) to estimate the value of (HI)A for each type of fuel. Instrumentation used to make these estimates is not subject to the calibration requirements of §98.3(i) or to the QA requirements of §98.34.

(D) Units in the Acid Rain Program and other units that report heat input data to EPA year-round according to part 75 of this chapter may use the best available information described in paragraph (c)(4)(ii)(C) of this section, to estimate (HI)A for each fuel type, whenever fuel-specific heat input values cannot be directly obtained from the electronic data reports under §75.64 of this chapter.

(5) When multiple fuels are combusted during the reporting year, sum the fuel-specific results from Equations C-8, C-8a, C-8b, C-9a, C-9b, or C-10 of this section (as applicable) to obtain the total annual CH4 and N2O emissions, in metric tons.

(6) Calculate the annual CH4 and N2O mass emissions from the combustion of blended fuels as follows:

(i) If the mass or volume of each component fuel in the blend is measured before the fuels are mixed and combusted, calculate and report CH4 and N2O emissions separately for each component fuel, using the applicable procedures in this paragraph (c).

(ii) If the mass or volume of each component fuel in the blend is not measured before the fuels are mixed and combusted, a reasonable estimate of the percentage composition of the blend, based on best available information, is required. Perform the following calculations for each component fuel “i” that is listed in Table C-2:

(A) Multiply (% Fuel)i, the estimated mass or volume percentage (decimal fraction) of component fuel “i”, by the total annual mass or volume of the blended fuel combusted during the reporting year, to obtain an estimate of the annual consumption of component “i”;

(B) Multiply the result from paragraph (c)(6)(ii)(A) of this section by the HHV of the fuel (default value or, if available, the measured annual average value), to obtain an estimate of the annual heat input from component “i”;

(C) Calculate the annual CH4 and N2O emissions from component “i”, using Equation C-8, C-8a, C-8b, C-9a, or C-10 of this section, as applicable;

(D) Sum the annual CH4 emissions across all component fuels to obtain the annual CH4 emissions for the blend. Similarly sum the annual N2O emissions across all component fuels to obtain the annual N2O emissions for the blend. Report these annual emissions totals.

(d) Calculation of CO2 from sorbent.

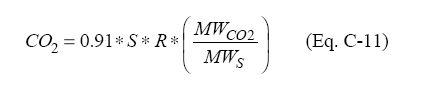

(1) When a unit is a fluidized bed boiler, is equipped with a wet flue gas desulfurization system, or uses other acid gas emission controls with sorbent injection to remove acid gases, if the chemical reaction between the acid gas and the sorbent produces CO2 emissions, use Equation C-11 of this section to calculate the CO2 emissions from the sorbent, except when those CO2 emissions are monitored by CEMS. When a sorbent other than CaCO3 is used, determine site-specific values of R and MWS.

Where:

CO2 = CO2 emitted from sorbent for the reporting year (metric tons).

S = Limestone or other sorbent used in the reporting year, from company records (short tons).

R = The number of moles of CO2 released upon capture of one mole of the acid gas species being removed (R = 1.00 when the sorbent is CaCO3 and the targeted acid gas species is SO2).

MWCO2 = Molecular weight of carbon dioxide (44).

MWS = Molecular weight of sorbent (100 if calcium carbonate).

0.91 = Conversion factor from short tons to metric tons.

(2) The total annual CO2 mass emissions reported for the unit shall include the CO2 emissions from the combustion process and the CO2 emissions from the sorbent.

(e) Biogenic CO2 emissions from combustion of biomass with other fuels. Use the applicable procedures of this paragraph (e) to estimate biogenic CO2 emissions from units that combust a combination of biomass and fossil fuels (i.e., either co-fired or blended fuels). Separate reporting of biogenic CO2 emissions from the combined combustion of biomass and fossil fuels is required for those biomass fuels listed in Table C-1 of this section and for municipal solid waste. In addition, when a biomass fuel that is not listed in Table C-1 is combusted in a unit that has a maximum rated heat input greater than 250 mmBtu/hr, if the biomass fuel accounts for 10% or more of the annual heat input to the unit, and if the unit does not use CEMS to quantify its annual CO2 mass emissions, then, pursuant to §98.33(b)(3)(iii), Tier 3 must be used to determine the carbon content of the biomass fuel and to calculate the biogenic CO2 emissions from combustion of the fuel. Notwithstanding these requirements, in accordance with §98.3(c)(12), separate reporting of biogenic CO2 emissions is optional for the 2010 reporting year for units subject to subpart D of this part and for units that use the CO2 mass emissions calculation methodologies in part 75 of this chapter, pursuant to paragraph (a)(5) of this section. However, if the owner or operator opts to report biogenic CO2 emissions separately for these units, the appropriate method(s) in this paragraph (e) shall be used. Separate reporting of biogenic CO2 emissions from the combustion of tires is also optional, but may be reported by following the provisions of paragraph (e)(3) of this section.

(1) You may use Equation C-1 of this subpart to calculate the annual CO2 mass emissions from the combustion of the biomass fuels listed in Table C-1 of this subpart (except MSW and tires), in a unit of any size, including units equipped with a CO2 CEMS, except when the use of Tier 2 is required as specified in paragraph (b)(1)(iv) of this section. Determine the quantity of biomass combusted using one of the following procedures in this paragraph (e)(1), as appropriate, and document the selected procedures in the Monitoring Plan under §98.3(g):

(i) Company records.

(ii) The procedures in paragraph (e)(4) of this section.

(iii) The best available information for premixed fuels that contain biomass and fossil fuels (e.g., liquid fuel mixtures containing biodiesel).

(2) You may use the procedures of this paragraph if the following three conditions are met: First, a CO2 CEMS (or a surrogate O2 monitor) and a stack gas flow rate monitor are used to determine the annual CO2 mass emissions (either according to part 75 of this chapter, the Tier 4 Calculation Methodology, or the alternative calculation methodology specified in paragraph (a)(5)(iii) of this section); second, neither MSW nor tires is combusted in the unit during the reporting year; and third, the CO2 emissions CO2 consist solely of combustion products (i.e., no process or sorbent emissions included).

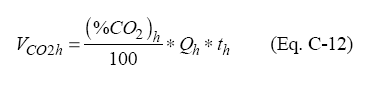

(i) For each operating hour, use Equation C–12 of this section to determine the volume of CO2 emitted.

Where:

VCO2h = Hourly volume of CO2 emitted (scf).

(%CO2)h = Hourly average CO2 concentration, measured by the CO2 concentration monitor, or, if applicable, calculated from the hourly average O2 concentration (%CO2).

Qh = Hourly average stack gas volumetric flow rate, measured by the stack gas volumetric flow rate monitor (scfh).

th = Source operating time (decimal fraction of the hour during which the source combusts fuel, i.e., 1.0 for a full operating hour, 0.5 for 30 minutes of operation, etc.).

100 = Conversion factor from percent to a decimal fraction.

(ii) Sum all of the hourly VCO2h values for the reporting year, to obtain Vtotal, the total annual volume of CO2 emitted.

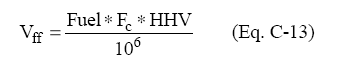

(iii) Calculate the annual volume of CO2 emitted from fossil fuel combustion using Equation C–13 of this section. If two or more types of fossil fuel are combusted during the year, perform a separate calculation with Equation C–13 of this section for each fuel and sum the results.

Where:

Vff = Annual volume of CO2 emitted from combustion of a particular fossil fuel (scf).

Fuel = Total quantity of the fossil fuel combusted in the reporting year, from company records, as defined in §98.6 (lb for solid fuel, gallons for liquid fuel, and scf for gaseous fuel).

Fc = Fuel-specific carbon based F-factor, either a default value from Table 1 in section 3.3.5 of appendix F to part 75 of this chapter, or a site-specific value determined under section 3.3.6 of appendix F to part 75 (scf CO2/mmBtu).

HHV = High heat value of the fossil fuel, from fuel sampling and analysis (annual average value in Btu/lb for solid fuel, Btu/gal for liquid fuel and Btu/scf for gaseous fuel, sampled as specified (e.g., monthly, quarterly, semi-annually, or by lot) in §98.34(a)(2)). The average HHV shall be calculated according to the requirements of paragraph (a)(2)(ii) of this section.

106 = Conversion factor, Btu per mmBtu.

(iv) Subtract Vff from Vtotal to obtain Vbio, the annual volume of CO2 from the combustion of biomass.

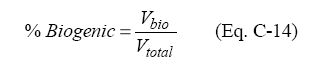

(v) Calculate the biogenic percentage of the annual CO2 emissions, expressed as a decimal fraction, using Equation C–14 of this section:

(vi) Calculate the annual biogenic CO2 mass emissions, in metric tons, by multiplying the results obtained from Equation C–14 of this section by the annual CO2 mass emissions in metric tons, as determined:

(A) Under paragraph (a)(4)(vi) of this section, for units using the Tier 4 Calculation Methodology.

(B) Under paragraph (a)(5)(iii)(B) of this section, for units using the alternative calculation methodology specified in paragraph (a)(5)(iii).

(C) From the electronic data report required under §75.64 of this chapter, for units in the Acid Rain Program and other units using CEMS to monitor and report CO2 mass emissions according to part 75 of this chapter. However, before calculating the annual biogenic CO2 mass emissions, multiply the cumulative annual CO2 mass emissions by 0.91 to convert from short tons to metric tons.

(3) You must use the procedures in paragraphs (e)(3)(i) through (e)(3)(iii) of this section to determine the annual biogenic CO2 emissions from the combustion of MSW, except as otherwise provided in paragraph (e)(3)(iv) of this section. These procedures also may be used for any unit that co-fires biomass and fossil fuels, including units equipped with a CO2 CEMS, and units for which optional separate reporting of biogenic CO2 emissions from the combustion of tires is selected.

(i) Use an applicable CO2 emissions calculation method in this section to quantify the total annual CO2 mass emissions from the unit.

(ii) Determine the relative proportions of biogenic and non-biogenic CO2 emissions in the flue gas on a quarterly basis using the method specified in §98.34(d) (for units that combust MSW as the primary fuel or as the only fuel with a biogenic component) or in §98.34(e) (for other units, including units that combust tires).

(iii) Determine the annual biogenic CO2 mass emissions from the unit by multiplying the total annual CO2 mass emissions by the annual average biogenic decimal fraction obtained from §98.34(d) or §98.34(e), as applicable.

(iv) If the combustion of MSW and/or tires provides no more than 10 percent of the annual heat input to a unit, or if a small, batch incinerator combusts no more than 1,000 tons per year of MSW, you may estimate the annual biogenic CO2 emissions as follows, in lieu of following the procedures in paragraphs (e)(3)(i) through (e)(3)(iii) of this section:

(A) Calculate the total annual CO2 emissions from combustion of MSW and/or tires in the unit, using the Tier 1 calculation methodology in paragraph (a)(1) of this section.

(B) Multiply the result from paragraph (e)(3)(iv)(A) of this section by the appropriate default factor to determine the annual biogenic CO2 emissions, in metric tons. For MSW, use a default factor of 0.60 and for tires, use a default factor of 0.20.

(4) As an alternative to the procedures in paragraph (e)(2) of this section, use ASTM Methods D7459–08 and D6866– 08 to determine the biogenic portion of the annual CO2 emissions, as described in §98.34(e). If this option is selected, the results of each determination shall be expressed as a decimal fraction (e.g., 0.30, if 30 percent of the CO2 is biogenic), and the values shall be averaged over the reporting year. The annual biogenic CO2 mass emissions shall be calculated by multiplying the the total annual CO2 mass emissions by the annual average biogenic fraction obtained from ASTM D6866–08 and ASTM D7459–08.

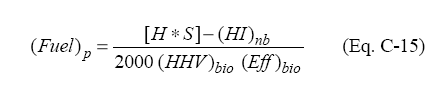

(4) If Equation C–1 of this section is selected to calculate the annual biogenic mass emissions for wood, wood waste, or other solid biomass-derived fuel, Equation C–15 of this section may be used to quantify biogenic fuel consumption, provided that all of the required input parameters are accurately quantified. Similar equations and calculation methodologies based on steam generation and boiler efficiency may be used, provided that they are documented in the GHG Monitoring Plan required by §98.3(g)(5).

Where:

(Fuel)p = Quantity of biomass consumed during the measurement period “p” (tons/ year or tons/month, as applicable).

H = Average enthalpy of the boiler steam for the measurement period (Btu/lb).

S = Total boiler steam production for the measurement period (lb/month or lb/year, as applicable).

(HI)nb = Heat input from co-fired fossil fuels and non-biomass-derived fuels for the measurement period, based on company records of fuel usage and default or measured HHV values (Btu/month or Btu/year, as applicable).

(HHV)bio = Default or measured high heat value of the biomass fuel (Btu/lb).

(Eff)bio = Percent efficiency of biomass-to-energy conversion, expressed as a decimal fraction.

2000 = Conversion factor (lb/ton).

(5) For units subject to subpart D of this part and for units that use the methods in part 75 of this chapter to quantify CO2 mass emissions in accordance with paragraph (a)(5) of this section, you may calculate biogenic CO2 emissions from the combustion of biomass fuels listed in Table C-1 of this subpart using Equation C-15a. This equation may not be used to calculate biogenic CO2 emissions from the combustion of tires or MSW; the methods described in paragraph (e)(3) of this section must be used for those fuels. Whenever (HI)A, the annual heat input from combustion of biomass fuel in Equation C-15a, cannot be determined solely from the information in the electronic emissions reports under §75.64 of this chapter (e.g., in cases where a unit uses CEMS in combination with multiple F-factors, a worst-case F-factor, or a prorated F-factor to report heat input rather than reporting heat input based on fuel type), use the best available information (as described in §§98.33(c)(4)(ii)(C) and (c)(4)(ii)(D)) to determine (HI)A.

CO2 = 0.001 * (HI)A * EF (Eq. C-15a)

Where:

CO2 = Annual CO2 mass emissions from the combustion of a particular type of biomass fuel listed in Table C-1 (metric tons)

(HI)A = Annual heat input from the biomass fuel, obtained, where feasible, from the electronic emissions reports required under §75.64 of this chapter. Where this is not feasible use best available information, as described in §§98.33(c)(4)(ii)(C) and (c)(4)(ii)(D) (mmBtu)

EF = CO2 emission factor for the biomass fuel, from Table C-1 (kg CO2/mmBtu)

0.001 = Conversion factor from kg to metric tons

[74 FR 56403, Oct. 30, 2009; 75 FR 79140, Dec. 17, 2010; 78 FR 71950, Nov. 29, 2013; 81 FR 89251, Dec. 9, 2016]