['Air Programs']

['Hazardous Air Pollutants']

05/05/2022

...

(a) If you wish to claim that your LMP is an area source, you must measure the emissions of hydrogen chloride from all lime kilns, except as provided in paragraph (c) of this section, at your plant using either:

(1) EPA Method 320 of appendix A to this part, or

(2) As an alternative to Method 320 of appendix A, ASTM D6348-03 (Reapproved 2010) including Annexes A1 through A8 (incorporated by reference—see §63.14). ASTM D6348-12e1 (incorporated by reference—see §63.14) is an acceptable alternative to EPA Method 320 of appendix A, provided that the provisions of paragraphs (a)(2)(i) and (ii) of this section are followed:

(i) The test plan preparation and implementation in the Annexes to ASTM D6348-03 (Reapproved 2010), Sections A1 through A8 are mandatory.

(ii) In ASTM D6348-03 (Reapproved 2010) Annex A5 (Analyte Spiking Technique), the percent recovery (%R) must be determined for each target analyte (Equation A5.5). In order for the test data to be acceptable for a compound, %R must be greater than or equal to 70 percent and less than or equal to 130 percent. If the %R value does not meet this criterion for a target compound, the test data are not acceptable for that compound and the test must be repeated for that analyte (i.e., the sampling and/or analytical procedure should be adjusted before a retest). The %R value for each compound must be reported in the test report, and all field measurements must be corrected with the calculated %R value for that compound by using the following equation: Reported Results = ((Measured Concentration in the Stack))/(%R) × 100; or

(3) EPA Method 321 of appendix A to this part, or

(4) As an alternative to EPA Method 321, ASTM Method D6735-01 (Reapproved 2009), (incorporated by reference—see §63.14), provided that the provisions in paragraphs (a)(3)(i) through (vi) of this section are followed.

(i) A test must include three or more runs in which a pair of samples is obtained simultaneously for each run according to section 11.2.6 of ASTM Method D6735-01 (Reapproved 2009).

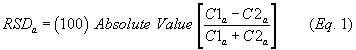

(ii) You must calculate the test run standard deviation of each set of paired samples to quantify data precision, according to Equation 1 of this section:

Where:

RSDa = The test run relative standard deviation of sample pair a, percent.

C1a and C2a = The HCl concentrations, milligram/dry standard cubic meter(mg/dscm), from the paired samples.

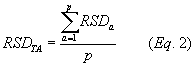

(iii) You must calculate the test average relative standard deviation according to Equation 2 of this section:

Where:

RSDTA = The test average relative standard deviation, percent.

RSDa = The test run relative standard deviation for sample pair a.

p = The number of test runs, ≥3.

(iv) If RSD TA is greater than 20 percent, the data are invalid and the test must be repeated.

(v) The post-test analyte spike procedure of section 11.2.7 of ASTM Method D6735-01 (Reapproved 2009) is conducted, and the percent recovery is calculated according to section 12.6 of ASTM Method D6735-01 (Reapproved 2009).

(vi) If the percent recovery is between 70 percent and 130 percent, inclusive, the test is valid. If the percent recovery is outside of this range, the data are considered invalid, and the test must be repeated.

(b) If you conduct tests to determine the rates of emission of specific organic HAP from lime kilns at LMP for use in applicability determinations under §63.7081, you may use either:

(1) Method 320 of appendix A to this part, or

(2) As an alternative to Method 320 of Appendix A, ASTM D6348-03 (Reapproved 2010) including Annexes A1 through A8 (incorporated by reference—see §63.14). ASTM D6348-12e1 (incorporated by reference—see §63.14) is an acceptable alternative to EPA Method 320 of appendix A, provided that the provisions of paragraphs (b)(2)(i) and (ii) of this section are followed:

(i) The test plan preparation and implementation in the Annexes to ASTM D6348-03 (Reapproved 2010), Sections A1 through A8 are mandatory.

(ii) In ASTM D6348-03 (Reapproved 2010) Annex A5 (Analyte Spiking Technique), the percent recovery (%R) must be determined for each target analyte (Equation A5.5). In order for the test data to be acceptable for a compound, %R must be greater than or equal to 70 percent and less than or equal to 130 percent. If the %R value does not meet this criterion for a target compound, the test data are not acceptable for that compound and the test must be repeated for that analyte (i.e., the sampling and/or analytical procedure should be adjusted before a retest). The %R value for each compound must be reported in the test report, and all field measurements must be corrected with the calculated %R value for that compound by using the following equation: Reported Results = ((Measured Concentration in the Stack))/(%R) × 100; or

(3) Method 18 of appendix A-6 to part 60 of this chapter; or

(4) As an alternative to Method 18, ASTM D6420-99 (Reapproved 2010), (incorporated by reference—see §63.14), provided that the provisions of paragraphs (b)(3)(i) through (iv) of this section are followed:

(i) The target compound(s) are those listed in section 1.1 of ASTM D6420-99 (Reapproved 2010) as measurable;

(ii) This ASTM should not be used for methane and ethane because their atomic mass is less than 35 and

(iii) ASTM D6420-99 (Reapproved 2010) should never be specified as a total VOC method.

(c) It is left to the discretion of the permitting authority whether or not idled kilns must be tested for (HCl) to claim area source status. If the facility has kilns that use common feed materials and fuel, are essentially identical in design, and use essentially identical emission controls, the permitting authority may also determine if one kiln can be tested, and the HCl emissions for the other essentially identical kilns be estimated from that test.

[85 FR 44981, July 24, 2020]

READ MORESHOW LESS

['Air Programs']

['Hazardous Air Pollutants']

Load More

J. J. Keller is the trusted source for DOT / Transportation, OSHA / Workplace Safety, Human Resources, Construction Safety and Hazmat / Hazardous Materials regulation compliance products and services. J. J. Keller helps you increase safety awareness, reduce risk, follow best practices, improve safety training, and stay current with changing regulations.

Copyright 2024 J. J. Keller & Associate, Inc. For re-use options please contact copyright@jjkeller.com or call 800-558-5011.