['Air Programs']

['Hazardous Air Pollutants']

02/27/2022

...

§63.1019 Applicability.

(a) The provisions of this subpart apply to the control of air emissions from equipment leaks for which another subpart references the use of this subpart for such air emission control. These air emission standards for equipment leaks are placed here for administrative convenience and only apply to those owners and operators of facilities subject to a referencing subpart. The provisions of 40 CFR part 63, subpart A (General Provisions) do not apply to this subpart except as noted in the referencing subpart.

(b) Equipment subject to this subpart. The provisions of this subpart and the referencing subpart apply to equipment that contains or contacts regulated material. This subpart applies to pumps, compressors, agitators, pressure relief devices, sampling connection systems, open-ended valves or lines, valves, connectors, instrumentation systems, and closed vent systems and control devices used to meet the requirements of this subpart.

(c) Equipment in vacuum service. Equipment in vacuum service is excluded from the requirements of this subpart.

(d) Equipment in service less than 300 hours per calendar year. Equipment intended to be in regulated material service less than 300 hours per calendar year is excluded from the requirements of §§63.1025 through 63.1034 and §63.1036 if it is identified as required in §63.1022(b)(5).

(e) Lines and equipment not containing process fluids. Lines and equipment not containing process fluids are not subject to the provisions of this subpart. Utilities, and other non-process lines, such as heating and cooling systems that do not combine their materials with those in the processes they serve, are not considered to be part of a process unit or affected facility.

(f) Implementation and enforcement. This subpart can be implemented and enforced by the U.S. Environmental Protection Agency (EPA), or a delegated authority such as the applicable State, local, or tribal agency. If the EPA Administrator has delegated authority to a State, local, or tribal agency, then that agency has the authority to implement and enforce this subpart. Contact the applicable EPA Regional Office to find out if this subpart is delegated to a State, local, or tribal agency.

(1) In delegating implementation and enforcement authority of this subpart to a State, local, or tribal agency under section 40 CFR part 63, subpart E, the authorities contained in paragraphs (f)(i) through (v) of this section are retained by the EPA Administrator and are not transferred to the State, local, or tribal agency.

(i) Approval of alternatives to the nonopacity emissions standards in §§63.1022 through 62.1034, under §63.6(g), and the standards for quality improvement programs in §63.1035. Where these standards reference another subpart, the cited provisions will be delegated according to the delegation provisions of the referenced subpart.

(ii) [Reserved]

(iii) Approval of major changes to test methods under §63.7(e)(2)(ii) and (f) and as defined in §63.90.

(iv) Approval of major changes to monitoring under §63.8(f) and as defined in §63.90.

(v) Approval of major changes to recordkeeping and reporting under §63.10(f) and as defined in §63.90.

[64 FR 34899, June 29, 1999, as amended at 67 FR 46279, July 12, 2002]

§63.1020 Definitions.

All terms used in this part shall have the meaning given them in the Act and in this section.

Batch process means a process in which the equipment is fed intermittently or discontinuously. Processing then occurs in this equipment after which the equipment is generally emptied. Examples of industries that use batch processes include pharmaceutical production and pesticide production.

Batch product-process equipment train means the collection of equipment (e.g., connectors, reactors, valves, pumps, etc.) configured to produce a specific product or intermediate by a batch process.

Car-seal means a seal that is placed on a device that is used to change the position of a valve (e.g., from opened to closed) in such a way that the position of the valve cannot be changed without breaking the seal.

Closed-loop system means an enclosed system that returns process fluid to the process and is not vented directly to the atmosphere.

Closed-purge system means a system or combination of systems and portable containers to capture purged liquids. Containers must be covered or closed when not being filled or emptied.

Closed-vent system means a system that is not open to the atmosphere and is composed of piping, ductwork, connections, and, if necessary, flow inducing devices that transport gas or vapor from an emission point to a control device.

Combustion device means an individual unit of equipment, such as a flare, incinerator, process heater, or boiler, used for the combustion of organic emissions.

Connector means flanged, screwed, or other joined fittings used to connect two pipelines or a pipeline and a piece of equipment. A common connector is a flange. Joined fittings welded completely around the circumference of the interface are not considered connectors for the purpose of this regulation. For the purpose of reporting and recordkeeping, connector means joined fittings that are not inaccessible, ceramic, or ceramic-lined (e.g., porcelain, glass, or glass-lined) as described in §63.1027(e)(2).

Continuous parameter monitoring system (CPMS) means the total equipment that may be required to meet the data acquisition and availability requirements of this part, used to sample, condition (if applicable), analyze, and provide a record of process or control system parameters.

Control device means any combustion device, recovery device, recapture device, or any combination of these devices used to comply with this part. Such equipment or devices include, but are not limited to, absorbers, carbon adsorbers, condensers, incinerators, flares, boilers, and process heaters. Primary condensers on steam strippers or fuel gas systems are not considered control devices.

Distance piece means an open or enclosed casing through which the piston rod travels, separating the compressor cylinder from the crankcase.

Double block and bleed system means two block valves connected in series with a bleed valve or line that can vent the line between the two block valves.

Equipment means each pump, compressor, agitator, pressure relief device, sampling connection system, open-ended valve or line, valve, connector, and instrumentation system in regulated material service; and any control devices or systems used to comply with this subpart.

First attempt at repair, for the purposes of this subpart, means to take action for the purpose of stopping or reducing leakage of organic material to the atmosphere, followed by monitoring as specified in §§63.1023(b) and (c) of this subpart in to verify whether the leak is repaired, unless the owner or operator determines by other means that the leak is not repaired.

Fuel gas means gases that are combusted to derive useful work or heat.

Fuel gas system means the offsite and onsite piping and flow and pressure control system that gathers gaseous stream(s) generated by onsite operations, may blend them with other sources of gas, and transports the gaseous stream for use a fuel gas in combustion equipment, such as furnaces and gas turbines, either singly or in combination.

In food and medical service means that a piece of equipment in regulated material service contacts a process stream used to manufacture a Food and Drug Administration regulated product where leakage of a barrier fluid into the process stream would cause any of the following:

(1) A dilution of product quality so that the product would not meet written specifications,

(2) An exothermic reaction which is a safety hazard,

(3) The intended reaction to be slowed down or stopped, or

(4) An undesired side reaction to occur.

In gas and vapor service means that a piece of equipment in regulated material service contains a gas or vapor at operating conditions.

In heavy liquid service means that a piece of equipment in regulated material service is not in gas and vapor service or in light liquid service.

In light liquid service means that a piece of equipment in regulated material service contains a liquid that meets the following conditions:

(1) The vapor pressure of one or more of the organic compounds is greater than 0.3 kilopascals at 20°C,

(2) The total concentration of the pure organic compounds constituents having a vapor pressure greater than 0.3 kilopascals at 20°C is equal to or greater than 20 percent by weight of the total process stream, and

(3) The fluid is a liquid at operating conditions.

(Note to definition of “in light liquid service”:

Vapor pressures may be determined by standard reference texts or ASTM D-2879.)

In liquid service means that a piece of equipment in regulated material service is not in gas and vapor service.

In organic hazardous air pollutant or in organic HAP service means that piece of equipment either contains or contracts a fluid (liquid or gas) that is at least 5 percent by weight of total organic HAP's as determined according to the provisions of §63.180(d) of subpart H. The provisions of §63.180(d) of subpart H also specify how to determine that a piece of equipment is not in organic HAP service.

In regulated material service means, for the purposes of this subpart, equipment which meets the definition of “in VOC service,” “in VHAP service,” “in organic hazardous air pollutant service,” or “in” other chemicals or groups of chemicals “service” as defined in the referencing subpart.

In-situ sampling systems means nonextractive samplers or in-line samplers.

In vacuum service means that equipment is operating at an internal pressure which is at least 5 kilopascals below ambient pressure.

Initial startup means for new sources, the first time the source begins production. For additions or changes not defined as a new source by this subpart, initial startup means the first time additional or changed equipment is put into operation. Initial startup does not include operation solely for testing of equipment. Initial startup does not include subsequent startup of process units following malfunction or process unit shutdowns. Except for equipment leaks, initial startup also does not include subsequent startups (of process units following changes in product for flexible operation units or following recharging of equipment in batch unit operations).

Instrumentation system means a group of equipment components used to condition and convey a sample of the process fluid to analyzers and instruments for the purpose of determining process operating conditions (e.g., composition, pressure, flow, etc.). Valves and connectors are the predominant type of equipment used in instrumentation systems; however, other types of equipment may also be included in these systems. Only valves nominally 1.27 centimeters (0.5 inches) and smaller, and connectors nominally 1.91 centimeters (0.75 inches) and smaller in diameter are considered instrumentation systems for the purposes of this subpart. Valves greater than nominally 1.27 centimeters (0.5 inches) and connectors greater than nominally 1.91 centimeters (0.75 inches) associated with instrumentation systems are not considered part of instrumentation systems and must be monitored individually.

Liquids dripping means any visible leakage from the seal including dripping, spraying, misting, clouding, and ice formation. Indications of liquids dripping include puddling or new stains that are indicative of an existing evaporated drip.

Nonrepairable means that it is technically infeasible to repair a piece of equipment from which a leak has been detected without a process unit or affected facility shutdown.

Open-ended valve or line means any valve, except relief valves, having one side of the valve seat in contact with process fluid and one side open to atmosphere, either directly or through open piping.

Organic monitoring device means a unit of equipment used to indicate the concentration level of organic compounds based on a detection principle such as infra-red, photoionization, or thermal conductivity.

Polymerizing monomer means a compound which may form polymer buildup in pump mechanical seals resulting in rapid mechanical seal failure.

Pressure release means the emission of materials resulting from the system pressure being greater than the set pressure of the relief device. This release can be one release or a series of releases over a short time period due to a malfunction in the process.

Pressure relief device or valve means a safety device used to prevent operating pressures from exceeding the maximum allowable working pressure of the process equipment. A common pressure relief device is a spring-loaded pressure relief valve. Devices that are actuated either by a pressure of less than or equal to 2.5 pounds per square inch gauge or by a vacuum are not pressure relief devices.

Process unit means the equipment specified in the definitions of process unit in the applicable referencing subpart. If the referencing subpart does not define process unit, then for the purposes of this part, process unit means the equipment assembled and connected by pipes or ducts to process raw materials and to manufacture an intended product.

Process unit shutdown means a work practice or operational procedure that stops production from a process unit, or part of a process unit during which it is technically feasible to clear process material from a process unit, or part of a process unit, consistent with safety constraints and during which repairs can be affected. The following are not considered process unit shutdowns:

(1) An unscheduled work practice or operations procedure that stops production from a process unit, or part of a process unit, for less than 24 hours.

(2) An unscheduled work practice or operations procedure that would stop production from a process unit, or part of a process unit, for a shorter period of time than would be required to clear the process unit, or part of the process unit, of materials and start up the unit, and would result in greater emissions than delay of repair of leaking components until the next scheduled process unit shutdown.

(3) The use of spare equipment and technically feasible bypassing of equipment without stopping production.

Referencing subpart means the subpart that refers an owner or operator to this subpart.

Regulated material, for purposes of this part, refers to gas from volatile organic liquids (VOL), volatile organic compounds (VOC), hazardous air pollutants (HAP), or other chemicals or groups of chemicals that are regulated by the referencing subpart.

Regulated source for the purposes of this part, means the stationary source, the group of stationary sources, or the portion of a stationary source that is regulated by a referencing subpart.

Relief device or valve means a valve used only to release an unplanned, nonroutine discharge. A relief valve discharge can result from an operator error, a malfunction such as a power failure or equipment failure, or other unexpected cause that requires immediate venting of gas from process equipment in order to avoid safety hazards or equipment damage.

Repaired, for the purposes of this subpart, means that equipment is adjusted, or otherwise altered, to eliminate a leak as defined in the applicable sections of this subpart and unless otherwise specified in applicable provisions of this subpart, is monitored as specified in §§63.1023(b) and (c) to verify that emissions from the equipment are below the applicable leak definition.

Routed to a process or route to a process means the emissions are conveyed to any enclosed portion of a process unit where the emissions are predominantly recycled and/or consumed in the same manner as a material that fulfills the same function in the process and/or transformed by chemical reaction into materials that are not regulated materials and/or incorporated into a product; and/or recovered.

Sampling connection system means an assembly of equipment within a process unit or affected facility used during periods of representative operation to take samples of the process fluid. Equipment used to take nonroutine grab samples is not considered a sampling connection system.

Screwed (threaded) connector means a threaded pipe fitting where the threads are cut on the pipe wall and the fitting requires only two pieces to make the connection (i.e., the pipe and the fitting).

Sensor means a device that measures a physical quantity or the change in a physical quantity, such as temperature, pressure, flow rate, pH, or liquid level.

Set pressure means for the purposes of this subpart, the pressure at which a properly operating pressure relief device begins to open to relieve atypical process system operating pressure.

Start-up means the setting into operation of a piece of equipment or a control device that is subject to this subpart.

§63.1021 Alternative means of emission limitation.

(a) Performance standard exemption. The provisions of paragraph (b) of this section do not apply to the performance standards of §63.1030(b) for pressure relief devices or §63.1031(f) for compressors operating under the alternative compressor standard.

(b) Requests by owners or operators. An owner or operator may request a determination of alternative means of emission limitation to the requirements of §§63.1025 through 63.1034 as provided in paragraph (d) of this section. If the Administrator makes a determination that a means of emission limitation is a permissible alternative, the owner or operator shall either comply with the alternative or comply with the requirements of §§63.1025 through 63.1034.

(c) Requests by manufacturers of equipment. (1) Manufacturers of equipment used to control equipment leaks of the regulated material may apply to the Administrator for permission for an alternative means of emission limitation that achieves a reduction in emissions of the regulated material achieved by the equipment, design, and operational requirements of this subpart.

(2) The Administrator will grant permission according to the provisions of paragraph (d) of this section.

(d) Permission to use an alternative means of emission limitation. Permission to use an alternative means of emission limitation shall be governed by the procedures in paragraphs (d)(1) through (d)(4) of this section.

(1) Where the standard is an equipment, design, or operational requirement, the requirements of paragraphs (d)(1)(i) through (d)(1)(iii) of this section apply.

(i) Each owner or operator applying for permission to use an alternative means of emission limitation shall be responsible for collecting and verifying emission performance test data for an alternative means of emission limitation.

(ii) The Administrator will compare test data for the means of emission limitation to test data for the equipment, design, and operational requirements.

(iii) The Administrator may condition the permission on requirements that may be necessary to ensure operation and maintenance to achieve at least the same emission reduction as the equipment, design, and operational requirements of this subpart.

(2) Where the standard is a work practice, the requirements of paragraphs (d)(2)(i) through (d)(2)(vi) of this section apply.

(i) Each owner or operator applying for permission to use an alternative means of emission limitation shall be responsible for collecting and verifying test data for the alternative.

(ii) For each kind of equipment for which permission is requested, the emission reduction achieved by the required work practices shall be demonstrated for a minimum period of 12 months.

(iii) For each kind of equipment for which permission is requested, the emission reduction achieved by the alternative means of emission limitation shall be demonstrated.

(iv) Each owner or operator applying for such permission shall commit, in writing, for each kind of equipment to work practices that provide for emission reductions equal to or greater than the emission reductions achieved by the required work practices.

(v) The Administrator will compare the demonstrated emission reduction for the alternative means of emission limitation to the demonstrated emission reduction for the required work practices and will consider the commitment in paragraph (d)(2)(iv) of this section.

(vi) The Administrator may condition the permission on requirements that may be necessary to ensure operation and maintenance to achieve the same or greater emission reduction as the required work practices of this subpart.

(3) An owner or operator may offer a unique approach to demonstrate the alternative means of emission limitation.

(4) If, in the judgement of the Administrator, an alternative means of emission limitation will be approved, the Administrator will publish a notice of the determination in the Federal Register using the procedures specified in the referencing subpart.

§63.1022 Equipment identification.

(a) General equipment identification. Equipment subject to this subpart shall be identified. Identification of the equipment does not require physical tagging of the equipment. For example, the equipment may be identified on a plant site plan, in log entries, by designation of process unit or affected facility boundaries by some form of weatherproof identification, or by other appropriate methods.

(b) Additional equipment identification. In addition to the general identification required by paragraph (a) of this section, equipment subject to any of the provisions in §§63.1023 through 63.1034 shall be specifically identified as required in paragraphs (b)(1) through (b)(5) of this section, as applicable. This paragraph does not apply to an owner or operator of a batch product process who elects to pressure test the batch product process equipment train pursuant to §63.1036.

(1) Connectors. Except for inaccessible, ceramic, or ceramic-lined connectors meeting the provision of §63.1027(e)(2) and instrumentation systems identified pursuant to paragraph (b)(4) of this section, identify the connectors subject to the requirements of this subpart. Connectors need not be individually identified if all connectors in a designated area or length of pipe subject to the provisions of this subpart are identified as a group, and the number of connectors subject is indicated. With respect to connectors, the identification shall be complete no later than the completion of the initial survey required by paragraph (a) of this section.

(2) Routed to a process or fuel gas system or equipped with a closed vent system and control device. Identify the equipment that the owner or operator elects to route to a process or fuel gas system or equip with a closed vent system and control device, under the provisions of §63.1026(e)(3) (pumps in light liquid service), §63.1028(e)(3) (agitators), §63.1030(d) (pressure relief devices in gas and vapor service), §63.1031(e) (compressors), or §63.1037(a) (alternative means of emission limitation for enclosed-vented process units).

(3) Pressure relief devices. Identify the pressure relief devices equipped with rupture disks, under the provisions of §63.1030(e).

(4) Instrumentation systems. Identify instrumentation systems subject to the provisions of §63.1029 of this subpart. Individual components in an instrumentation system need not be identified.

(5) Equipment in service less than 300 hours per calendar year. The identity, either by list, location (area or group), or other method, of equipment in regulated material service less than 300 hours per calendar year within a process unit or affected facilities subject to the provisions of this subpart shall be recorded.

(c) Special equipment designations: Equipment that is unsafe or difficult-to-monitor - (1) Designation and criteria for unsafe-to-monitor. Valves meeting the provisions of §63.1025(e)(1), pumps meeting the provisions of §63.1026(e)(6), connectors meeting the provisions of §63.1027(e)(1), and agitators meeting the provisions of §63.1028(e)(7) may be designated unsafe-to-monitor if the owner or operator determines that monitoring personnel would be exposed to an immediate danger as a consequence of complying with the monitoring requirements of this subpart. Examples of unsafe-to-monitor equipment include, but is not limited to, equipment under extreme pressure or heat.

(2) Designation and criteria for difficult-to-monitor. Valves meeting the provisions of §63.1025(e)(2) may be designated difficult-to-monitor if the provisions of paragraph (c)(2)(i) apply. Agitators meeting the provisions of §63.1028(e)(5) may be designated difficult-to-monitor if the provisions of paragraph (c)(2)(ii) apply.

(i) Valves. (A) The owner or operator of the valve determines that the valve cannot be monitored without elevating the monitoring personnel more than 2 meters (7 feet) above a support surface or it is not accessible in a safe manner when it is in regulated material service; and

(B) The process unit or affected facility within which the valve is located is an existing source, or the owner or operator designates less than 3 percent of the total number of valves in a new source as difficult-to-monitor.

(ii) Agitators. The owner or operator determines that the agitator cannot be monitored without elevating the monitoring personnel more than 2 meters (7 feet) above a support surface or it is not accessible in a safe manner when it is in regulated material service.

(3) Identification of unsafe or difficult-to-monitor equipment. The owner or operator shall record the identity of equipment designated as unsafe-to-monitor according to the provisions of paragraph (c)(1) of this section and the planned schedule for monitoring this equipment. The owner or operator shall record the identity of equipment designated as difficult-to-monitor according to the provisions of paragraph (c)(2) of this section, the planned schedule for monitoring this equipment, and an explanation why the equipment is unsafe or difficult-to-monitor. This record must be kept at the plant and be available for review by an inspector.

(4) Written plan requirements. (i) The owner or operator of equipment designated as unsafe-to-monitor according to the provisions of paragraph (c)(1) of this section shall have a written plan that requires monitoring of the equipment as frequently as practical during safe-to-monitor times, but not more frequently than the periodic monitoring schedule otherwise applicable, and repair of the equipment according to the procedures in §63.1024 if a leak is detected.

(ii) The owner or operator of equipment designated as difficult-to-monitor according to the provisions of paragraph (c)(2) of this section shall have a written plan that requires monitoring of the equipment at least once per calendar year and repair of the equipment according to the procedures in §63.1024 if a leak is detected.

(d) Special equipment designations: Equipment that is unsafe-to-repair - (1) Designation and criteria. Connectors subject to the provisions of §63.1024(e) may be designated unsafe-to-repair if the owner or operator determines that repair personnel would be exposed to an immediate danger as a consequence of complying with the repair requirements of this subpart, and if the connector will be repaired before the end of the next process unit or affected facility shutdown as specified in §63.1024(e)(2).

(2) Identification of equipment. The identity of connectors designated as unsafe-to-repair and an explanation why the connector is unsafe-to-repair shall be recorded.

(e) Special equipment designations: Compressors operating with an instrument reading of less than 500 parts per million above background. Identify the compressors that the owner or operator elects to designate as operating with an instrument reading of less than 500 parts per million above background, under the provisions of §63.1031(f).

(f) Special equipment designations: Equipment in heavy liquid service. The owner or operator of equipment in heavy liquid service shall comply with the requirements of either paragraph (f)(1) or (f)(2) of this section, as provided in paragraph (f)(3) of this section.

(1) Retain information, data, and analyses used to determine that a piece of equipment is in heavy liquid service.

(2) When requested by the Administrator, demonstrate that the piece of equipment or process is in heavy liquid service.

(3) A determination or demonstration that a piece of equipment or process is in heavy liquid service shall include an analysis or demonstration that the process fluids do not meet the definition of “in light liquid service.” Examples of information that could document this include, but are not limited to, records of chemicals purchased for the process, analyses of process stream composition, engineering calculations, or process knowledge.

§63.1023 Instrument and sensory monitoring for leaks.

(a) Monitoring for leaks. The owner or operator of a regulated source subject to this subpart shall monitor regulated equipment as specified in paragraph (a)(1) of this section for instrument monitoring and paragraph (a)(2) of this section for sensory monitoring.

(1) Instrument monitoring for leaks. (i) Valves in gas and vapor service and in light liquid service shall be monitored pursuant to §63.1025(b).

(ii) Pumps in light liquid service shall be monitored pursuant to §63.1026(b).

(iii) Connectors in gas and vapor service and in light liquid service shall be monitored pursuant to §63.1027(b).

(iv) Agitators in gas and vapor service and in light liquid service shall be monitored pursuant to §63.1028(c).

(v) Pressure relief devices in gas and vapor service shall be monitored pursuant to §63.1030(c).

(vi) Compressors designated to operate with an instrument reading less than 500 parts per million above background, as described in §63.1022(e), shall be monitored pursuant to §63.1031(f).

(2) Sensory monitoring for leaks. (i) Pumps in light liquid service shall be observed pursuant to §§63.1026(b)(4) and (e)(1)(v).

(ii) [Reserved]

(iii) Agitators in gas and vapor service and in light liquid service shall be observed pursuant to §63.1028(c)(3) or (e)(1)(iv).

(iv) [Reserved]

(b) Instrument monitoring methods. Instrument monitoring, as required under this subpart, shall comply with the requirements specified in paragraphs (b)(1) through (b)(6) of this section.

(1) Monitoring method. Monitoring shall comply with Method 21 of 40 CFR part 60, appendix A, except as otherwise provided in this section.

(2) Detection instrument performance criteria. (i) Except as provided for in paragraph (b)(2)(ii) of this section, the detection instrument shall meet the performance criteria of Method 21 of 40 CFR part 60, appendix A, except the instrument response factor criteria in section 3.1.2, paragraph (a) of Method 21 shall be for the representative composition of the process fluid not each individual VOC in the stream. For process streams that contain nitrogen, air, water or other inerts that are not HAP or VOC, the representative stream response factor shall be determined on an inert-free basis. The response factor may be determined at any concentration for which monitoring for leaks will be conducted.

(ii) If there is no instrument commercially available that will meet the performance criteria specified in paragraph (b)(2)(i) of this section, the instrument readings may be adjusted by multiplying by the representative response factor of the process fluid, calculated on an inert-free basis as described in paragraph (b)(2)(i) of this section.

(3) Detection instrument calibration procedure. The detection instrument shall be calibrated before use on each day of its use by the procedures specified in Method 21 of 40 CFR part 60, appendix A.

(4) Detection instrument calibration gas. Calibration gases shall be zero air (less than 10 parts per million of hydrocarbon in air); and the gases specified in paragraph (b)(4)(i) of this section except as provided in paragraph (b)(4)(ii) of this section.

(i) Mixtures of methane in air at a concentration no more than 2,000 parts per million greater than the leak definition concentration of the equipment monitored. If the monitoring instrument's design allows for multiple calibration scales, then the lower scale shall be calibrated with a calibration gas that is no higher than 2,000 parts per million above the concentration specified as a leak, and the highest scale shall be calibrated with a calibration gas that is approximately equal to 10,000 parts per million. If only one scale on an instrument will be used during monitoring, the owner or operator need not calibrate the scales that will not be used during that day's monitoring.

(ii) A calibration gas other than methane in air may be used if the instrument does not respond to methane or if the instrument does not meet the performance criteria specified in paragraph (b)(2)(i) of this section. In such cases, the calibration gas may be a mixture of one or more of the compounds to be measured in air.

(5) Monitoring performance. Monitoring shall be performed when the equipment is in regulated material service or is in use with any other detectable material.

(6) Monitoring data. Monitoring data obtained prior to the regulated source becoming subject to the referencing subpart that do not meet the criteria specified in paragraphs (b)(1) through (b)(5) of this section may still be used to qualify initially for less frequent monitoring under the provisions in §63.1025(a)(2), (b)(3) or (b)(4) for valves or §63.1027(b)(3) for connectors provided the departures from the criteria or from the specified monitoring frequency of §63.1025(b)(3) or (b)(4) or §63.1027(b)(3) are minor and do not significantly affect the quality of the data. Examples of minor departures are monitoring at a slightly different frequency (such as every 6 weeks instead of monthly or quarterly), following the performance criteria of section 3.1.2, paragraph (a) of Method 21 of appendix A of 40 CFR part 60 instead of paragraph (b)(2) of this section, or monitoring using a different leak definition if the data would indicate the presence or absence of a leak at the concentration specified in this subpart. Failure to use a calibrated instrument is not considered a minor departure.

(c) Instrument monitoring using background adjustments. The owner or operator may elect to adjust or not to adjust the instrument readings for background. If an owner or operator elects not to adjust instrument readings for background, the owner or operator shall monitor the equipment according to the procedures specified in paragraphs (b)(1) through (b)(5) of this section. In such cases, all instrument readings shall be compared directly to the applicable leak definition for the monitored equipment to determine whether there is a leak or to determine compliance with §63.1030(b) (pressure relief devices) or §63.1031(f) (alternative compressor standard). If an owner or operator elects to adjust instrument readings for background, the owner or operator shall monitor the equipment according to the procedures specified in paragraphs (c)(1) through (c)(4) of this section.

(1) The requirements of paragraphs (b)(1) through (b)(5) of this section shall apply.

(2) The background level shall be determined, using the procedures in Method 21 of 40 CFR part 60, appendix A.

(3) The instrument probe shall be traversed around all potential leak interfaces as close to the interface as possible as described in Method 21 of 40 CFR part 60, r40CFR63.1022.

(4) The arithmetic difference between the maximum concentration indicated by the instrument and the background level shall be compared to the applicable leak definition for the monitored equipment to determine whether there is a leak or to determine compliance with §63.1030(b) (pressure relief devices) or §63.1031(f) (alternative compressor standard).

(d) Sensory monitoring methods. Sensory monitoring consists of visual, audible, olfactory, or any other detection method used to determine a potential leak to the atmosphere.

(e) Leaking equipment identification and records. (1) When each leak is detected pursuant to the monitoring specified in paragraph (a) of this section, a weatherproof and readily visible identification, shall be attached to the leaking equipment.

(2) When each leak is detected, the information specified in §63.1024(f) shall be recorded and kept pursuant to the referencing subpart, except for the information for connectors complying with the 8 year monitoring period allowed under §63.1027(b)(3)(iii) shall be kept 5 years beyond the date of its last use.

§63.1024 Leak repair.

(a) Leak repair schedule. The owner or operator shall repair each leak detected as soon as practical, but not later than 15 calendar days after it is detected, except as provided in paragraphs (d) and (e) of this section. A first attempt at repair as defined in this subpart shall be made no later than 5 calendar days after the leak is detected. First attempt at repair for pumps includes, but is not limited to, tightening the packing gland nuts and/or ensuring that the seal flush is operating at design pressure and temperature. First attempt at repair for valves includes, but is not limited to, tightening the bonnet bolts, and/or replacing the bonnet bolts, and/or tightening the packing gland nuts, and/or injecting lubricant into the lubricated packing.

(b) [Reserved]

(c) Leak identification removal - (1) Valves and connectors in gas/vapor and light liquid service. The leak identification on a valve in gas/vapor or light liquid service may be removed after it has been monitored as specified in §63.1025(d)(2), and no leak has been detected during that monitoring. The leak identification on a connector in gas/vapor or light liquid service may be removed after it has been monitored as specified in §63.1027(b)(3)(iv) and no leak has been detected during that monitoring.

(2) Other equipment. The identification that has been placed, pursuant to §63.1023(e)(1), on equipment determined to have a leak, except for a valve or for a connector in gas/vapor or light liquid service that is subject to the provisions of §63.1027(b)(3)(iv), may be removed after it is repaired.

(d) Delay of repair. Delay of repair is allowed for any of the conditions specified in paragraphs (d)(1) through (d)(5) of this section. The owner or operator shall maintain a record of the facts that explain any delay of repairs and, where appropriate, why the repair was technically infeasible without a process unit shutdown.

(1) Delay of repair of equipment for which leaks have been detected is allowed if repair within 15 days after a leak is detected is technically infeasible without a process unit or affected facility shutdown. Repair of this equipment shall occur as soon as practical, but no later than the end of the next process unit or affected facility shutdown, except as provided in paragraph (d)(5) of this section.

(2) Delay of repair of equipment for which leaks have been detected is allowed for equipment that is isolated from the process and that does not remain in regulated material service.

(3) Delay of repair for valves, connectors, and agitators is also allowed if the provisions of paragraphs (d)(3)(i) and (d)(3)(ii) of this section are met.

(i) The owner or operator determines that emissions of purged material resulting from immediate repair would be greater than the fugitive emissions likely to result from delay of repair, and

(ii) When repair procedures are effected, the purged material is collected and destroyed, collected and routed to a fuel gas system or process, or recovered in a control device complying with either §63.1034 or §63.1021(b) of this part.

(4) Delay of repair for pumps is also allowed if the provisions of paragraphs (d)(4)(i) and (d)(4)(ii) of this section are met.

(i) Repair requires replacing the existing seal design with a new system that the owner or operator has determined under the provisions of §63.1035(d) will provide better performance or one of the specifications of paragraphs (d)(4)(i)(A) through (d)(4)(i)(C) of this section are met.

(A) A dual mechanical seal system that meets the requirements of §63.1026(e)(1) will be installed;

(B) A pump that meets the requirements of §63.1026(e)(2) will be installed; or

(C) A system that routes emissions to a process or a fuel gas system or a closed vent system and control device that meets the requirements of §63.1026(e)(3) will be installed; and

(ii) Repair is completed as soon as practical, but not later than 6 months after the leak was detected.

(5) Delay of repair beyond a process unit or affected facility shutdown will be allowed for a valve if valve assembly replacement is necessary during the process unit or affected facility shutdown, and valve assembly supplies have been depleted, and valve assembly supplies had been sufficiently stocked before the supplies were depleted. Delay of repair beyond the second process unit or affected facility shutdown will not be allowed unless the third process unit or affected facility shutdown occurs sooner than 6 months after the first process unit or affected facility shutdown.

(e) Unsafe-to-repair - connectors. Any connector that is designated, as described in §63.1022(d), as an unsafe-to-repair connector is exempt from the requirements of §63.1027(d), and paragraph (a) of this section.

(f) Leak repair records. For each leak detected, the information specified in paragraphs (f)(1) through (f)(5) of this section shall be recorded and maintained pursuant to the referencing subpart.

(1) The date of first attempt to repair the leak.

(2) The date of successful repair of the leak.

(3) Maximum instrument reading measured by Method 21 of 40 CFR part 60, appendix A at the time the leak is successfully repaired or determined to be nonrepairable.

(4) “Repair delayed” and the reason for the delay if a leak is not repaired within 15 calendar days after discovery of the leak as specified in paragraphs (f)(4)(i) and (f)(4)(ii) of this section.

(i) The owner or operator may develop a written procedure that identifies the conditions that justify a delay of repair. The written procedures may be included as part of the startup, shutdown, and malfunction plan, as required by the referencing subpart for the source, or may be part of a separate document that is maintained at the plant site. In such cases, reasons for delay of repair may be documented by citing the relevant sections of the written procedure.

(ii) If delay of repair was caused by depletion of stocked parts, there must be documentation that the spare parts were sufficiently stocked on-site before depletion and the reason for depletion.

(5) Dates of process unit or affected facility shutdowns that occur while the equipment is unrepaired.

§63.1025 Valves in gas and vapor service and in light liquid service standards.

(a) Compliance schedule. (1) The owner or operator shall comply with this section no later than the compliance dates specified in the referencing subpart.

(2) The use of monitoring data generated before the regulated source became subject to the referencing subpart to qualify initially for less frequent monitoring is governed by the provisions of §63.1023(b)(6).

(b) Leak detection. Unless otherwise specified in §63.1021(b) or paragraph (e) of this section, or the referencing subpart, the owner or operator shall monitor all valves at the intervals specified in paragraphs (b)(3) and/or (b)(4) of this section and shall comply with all other provisions of this section.

(1) Monitoring method. The valves shall be monitored to detect leaks by the method specified in §63.1023(b) and, as applicable, §63.1023(c).

(2) Instrument reading that defines a leak. The instrument reading that defines a leak is 500 parts per million or greater.

(3) Monitoring frequency. The owner or operator shall monitor valves for leaks at the intervals specified in paragraphs (b)(3)(i) through (b)(3)(v) of this section and shall keep the record specified in paragraph (b)(3)(vi) of this section.

(i) If at least the greater of 2 valves or 2 percent of the valves in a process unit leak, as calculated according to paragraph (c) of this section, the owner or operator shall monitor each valve once per month.

(ii) At process units with less than the greater of 2 leaking valves or 2 percent leaking valves, the owner or operator shall monitor each valve once each quarter, except as provided in paragraphs (b)(3)(iii) through (b)(3)(v) of this section. Monitoring data generated before the regulated source became subject to the referencing subpart and meeting the criteria of either §63.1023(b)(1) through (b)(5), or §63.1023(b)(6), may be used to qualify initially for less frequent monitoring under paragraphs (b)(3)(iii) through (b)(3)(v) of this section.

(iii) At process units with less than 1 percent leaking valves, the owner or operator may elect to monitor each valve once every two quarters

(iv) At process units with less than 0.5 percent leaking valves, the owner or operator may elect to monitor each valve once every four quarters.

(v) At process units with less than 0.25 percent leaking valves, the owner or operator may elect to monitor each valve once every 2 years.

(vi) The owner or operator shall keep a record of the monitoring schedule for each process unit.

(4) Valve subgrouping. For a process unit or a group of process units to which this subpart applies, an owner or operator may choose to subdivide the valves in the applicable process unit or group of process units and apply the provisions of paragraph (b)(3) of this section to each subgroup. If the owner or operator elects to subdivide the valves in the applicable process unit or group of process units, then the provisions of paragraphs (b)(4)(i) through (b)(4)(viii) of this section apply.

(i) The overall performance of total valves in the applicable process unit or group of process units to be subdivided shall be less than 2 percent leaking valves, as detected according to paragraphs (b)(1) and (b)(2) of this section and as calculated according to paragraphs (c)(1)(ii) and (c)(2) of this section.

(ii) The initial assignment or subsequent reassignment of valves to subgroups shall be governed by the provisions of paragraphs (b)(4)(ii)(A) through (b)(4)(ii)(C) of this section.

(A) The owner or operator shall determine which valves are assigned to each subgroup. Valves with less than one year of monitoring data or valves not monitored within the last twelve months must be placed initially into the most frequently monitored subgroup until at least one year of monitoring data have been obtained.

(B) Any valve or group of valves can be reassigned from a less frequently monitored subgroup to a more frequently monitored subgroup provided that the valves to be reassigned were monitored during the most recent monitoring period for the less frequently monitored subgroup. The monitoring results must be included with that less frequently monitored subgroup's associated percent leaking valves calculation for that monitoring event.

(C) Any valve or group of valves can be reassigned from a more frequently monitored subgroup to a less frequently monitored subgroup provided that the valves to be reassigned have not leaked for the period of the less frequently monitored subgroup (e.g., for the last 12 months, if the valve or group of valves is to be reassigned to a subgroup being monitored annually). Nonrepairable valves may not be reassigned to a less frequently monitored subgroup.

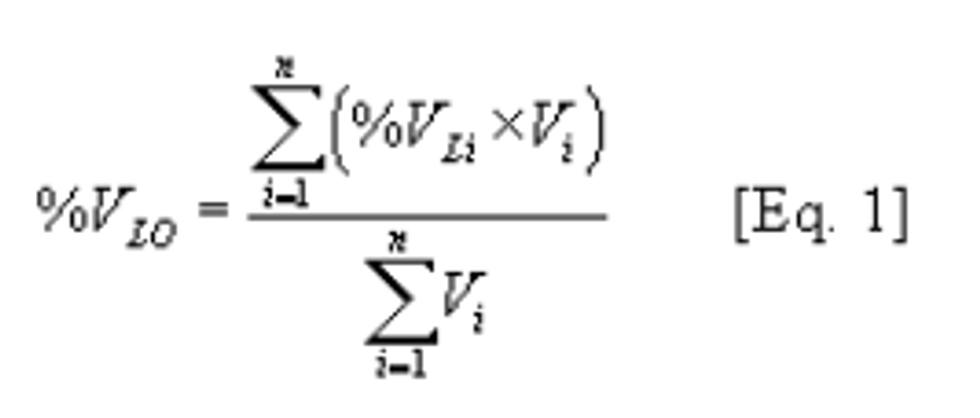

(iii) The owner or operator shall determine every 6 months if the overall performance of total valves in the applicable process unit or group of process units is less than 2 percent leaking valves and so indicate the performance in the next Periodic Report. If the overall performance of total valves in the applicable process unit or group of process units is 2 percent leaking valves or greater, the owner or operator shall no longer subgroup and shall revert to the program required in paragraphs (b)(1) through (b)(3) of this section for that applicable process unit or group of process units. An owner or operator can again elect to comply with the valve subgrouping procedures of paragraph (b)(4) of this section if future overall performance of total valves in the process unit or group of process units is again less than 2 percent. The overall performance of total valves in the applicable process unit or group of process units shall be calculated as a weighted average of the percent leaking valves of each subgroup according to Equation number 1:

where:

%VLO = Overall performance of total valves in the applicable process unit or group of process units

%VLi = Percent leaking valves in subgroup i, most recent value calculated according to the procedures in paragraphs (c)(1)(ii) and (c)(2) of this section.

Vi = Number of valves in subgroup i.

n = Number of subgroups.

(iv) The owner or operator shall maintain records specified in paragraphs (b)(4)(iv)(A) through (b)(4)(iv)(D) of this section.

(A) Which valves are assigned to each subgroup,

(B) Monitoring results and calculations made for each subgroup for each monitoring period,

(C) Which valves are reassigned, the last monitoring result prior to reassignment, and when they were reassigned, and

(D) The results of the semiannual overall performance calculation required in paragraph (b)(4)(iii) of this section.

(v) The owner or operator shall notify the Administrator no later than 30 days prior to the beginning of the next monitoring period of the decision to subgroup valves. The notification shall identify the participating process units and the number of valves assigned to each subgroup, if applicable, and may be included in the next Periodic Report.

(vi) The owner or operator shall submit in the periodic reports the information specified in paragraphs (b)(4)(vi)(A) and (b)(4)(vi)(B).

(A) Total number of valves in each subgroup, and

(B) Results of the semiannual overall performance calculation required by paragraph (b)(4)(iii) of this section.

(vii) To determine the monitoring frequency for each subgroup, the calculation procedures of paragraph (c)(2) of this section shall be used.

(viii) Except for the overall performance calculations required by paragraphs (b)(4)(i) and (iii) of this section, each subgroup shall be treated as if it were a process unit for the purposes of applying the provisions of this section.

(c) Percent leaking valves calculation - (1) Calculation basis and procedures. (i) The owner or operator shall decide no later than the compliance date of this part or upon revision of an operating permit whether to calculate percent leaking valves on a process unit or group of process units basis. Once the owner or operator has decided, all subsequent percentage calculations shall be made on the same basis and this shall be the basis used for comparison with the subgrouping criteria specified in paragraph (b)(4)(i) of this section.

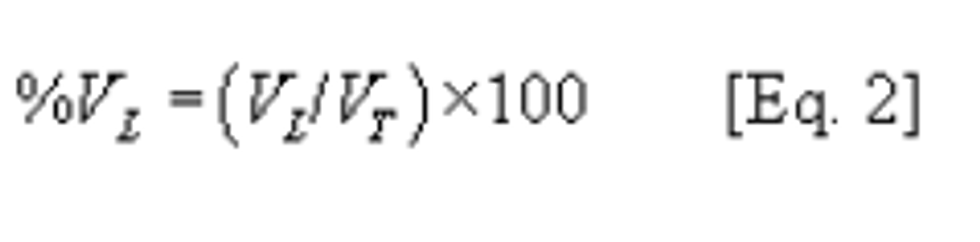

(ii) The percent leaking valves for each monitoring period for each process unit or valve subgroup, as provided in paragraph (b)(4) of this section, shall be calculated using the following equation:

where:

%VL = Percent leaking valves.

VL = Number of valves found leaking, excluding nonrepairable valves, as provided in paragraph (c)(3) of this section, and including those valves found leaking pursuant to paragraphs (d)(2)(iii)(A) and (d)(2)(iii)(B) of this section.

VT = The sum of the total number of valves monitored.

(2) Calculation for monitoring frequency. When determining monitoring frequency for each process unit or valve subgroup subject to monthly, quarterly, or semiannual monitoring frequencies, the percent leaking valves shall be the arithmetic average of the percent leaking valves from the last two monitoring periods. When determining monitoring frequency for each process unit or valve subgroup subject to annual or biennial (once every 2 years) monitoring frequencies, the percent leaking valves shall be the arithmetic average of the percent leaking valves from the last three monitoring periods.

(3) Nonrepairable valves. (i) Nonrepairable valves shall be included in the calculation of percent leaking valves the first time the valve is identified as leaking and nonrepairable and as required to comply with paragraph (c)(3)(ii) of this section. Otherwise, a number of nonrepairable valves (identified and included in the percent leaking valves calculation in a previous period) up to a maximum of 1 percent of the total number of valves in regulated material service at a process unit or affected facility may be excluded from calculation of percent leaking valves for subsequent monitoring periods.

(ii) If the number of nonrepairable valves exceeds 1 percent of the total number of valves in regulated material service at a process unit or affected facility, the number of nonrepairable valves exceeding 1 percent of the total number of valves in regulated material service shall be included in the calculation of percent leaking valves.

(d) Leak repair. (1) If a leak is determined pursuant to paragraph (b), (e)(1), or (e)(2) of this section, then the leak shall be repaired using the procedures in §63.1024, as applicable.

(2) After a leak has been repaired, the valve shall be monitored at least once within the first 3 months after its repair. The monitoring required by this paragraph is in addition to the monitoring required to satisfy the definition of repaired and first attempt at repair.

(i) The monitoring shall be conducted as specified in §63.1023(b) and (c) of this section, as appropriate, to determine whether the valve has resumed leaking.

(ii) Periodic monitoring required by paragraph (b) of this section may be used to satisfy the requirements of this paragraph, if the timing of the monitoring period coincides with the time specified in this paragraph. Alternatively, other monitoring may be performed to satisfy the requirements of this paragraph, regardless of whether the timing of the monitoring period for periodic monitoring coincides with the time specified in this paragraph.

(iii) If a leak is detected by monitoring that is conducted pursuant to paragraph (d)(2) of this section, the owner or operator shall follow the provisions of paragraphs (d)(2)(iii)(A) and (d)(2)(iii)(B) of this section, to determine whether that valve must be counted as a leaking valve for purposes of paragraph (c)(1)(ii) of this section.

(A) If the owner or operator elected to use periodic monitoring required by paragraph (b) of this section to satisfy the requirements of paragraph (d)(2) of this section, then the valve shall be counted as a leaking valve.

(B) If the owner or operator elected to use other monitoring, prior to the periodic monitoring required by paragraph (b) of this section, to satisfy the requirements of paragraph (d)(2) of this section, then the valve shall be counted as a leaking valve unless it is repaired and shown by periodic monitoring not to be leaking.

(e) Special provisions for valves - (1) Unsafe-to-monitor valves. Any valve that is designated, as described in §63.1022(c)(1), as an unsafe-to-monitor valve is exempt from the requirements of paragraphs (b) and (d)(2) of this section and the owner or operator shall monitor the valve according to the written plan specified in §63.1022(c)(4).

(2) Difficult-to-monitor valves. Any valve that is designated, as described in §63.1022(c)(2), as a difficult-to-monitor valve is exempt from the requirements of paragraph (b) of this section and the owner or operator shall monitor the valve according to the written plan specified in §63.1022(c)(4).

(3) Fewer than 250 valves. Any equipment located at a plant site with fewer than 250 valves in regulated material service is exempt from the requirements for monthly monitoring specified in paragraph (b)(3)(i) of this section. Instead, the owner or operator shall monitor each valve in regulated material service for leaks once each quarter, as provided in paragraphs (e)(1) and (e)(2) of this section.

§63.1026 Pumps in light liquid service standards.

(a) Compliance schedule. The owner or operator shall comply with this section no later than the compliance dates specified in the referencing subpart.

(b) Leak detection. Unless otherwise specified in §63.1021(b), §63.1036, §63.1037, or paragraph (e) of this section, the owner or operator shall monitor each pump to detect leaks and shall comply with all other provisions of this section.

(1) Monitoring method and frequency. The pumps shall be monitored monthly to detect leaks by the method specified in §63.1023(b) and, as applicable, §63.1023(c).

(2) Instrument reading that defines a leak. The instrument reading that defines a leak is specified in paragraphs (b)(2)(i) through (b)(2)(iii) of this section.

(i) 5,000 parts per million or greater for pumps handling polymerizing monomers;

(ii) 2,000 parts per million or greater for pumps in food/medical service; and

(iii) 1,000 parts per million or greater for all other pumps.

(3) Leak repair exception. For pumps to which a 1,000 parts per million leak definition applies, repair is not required unless an instrument reading of 2,000 parts per million or greater is detected.

(4) Visual inspection. Each pump shall be checked by visual inspection each calendar week for indications of liquids dripping from the pump seal. The owner or operator shall document that the inspection was conducted and the date of the inspection. If there are indications of liquids dripping from the pump seal at the time of the weekly inspection, the owner or operator shall follow the procedure specified in either paragraph (b)(4)(i) or (b)(4)(ii) of this section.

(i) The owner or operator shall monitor the pump as specified in §63.1023(b) and, as applicable, §63.1023(c). If the instrument reading indicates a leak as specified in paragraph (b)(2) of this section, a leak is detected and it shall be repaired using the procedures in §63.1024, except as specified in paragraph (b)(3) of this section; or

(ii) The owner or operator shall eliminate the visual indications of liquids dripping.

(c) Percent leaking pumps calculation. (1) The owner or operator shall decide no later than the compliance date of this part or upon revision of an operating permit whether to calculate percent leaking pumps on a process unit basis or group of process units basis. Once the owner or operator has decided, all subsequent percentage calculations shall be made on the same basis.

(2) If, when calculated on a 6-month rolling average, at least the greater of either 10 percent of the pumps in a process unit or three pumps in a process unit leak, the owner or operator shall implement a quality improvement program for pumps that complies with the requirements of §63.1035.

(3) The number of pumps at a process unit or affected facility shall be the sum of all the pumps in regulated material service, except that pumps found leaking in a continuous process unit or affected facility within 1 month after start-up of the pump shall not count in the percent leaking pumps calculation for that one monitoring period only.

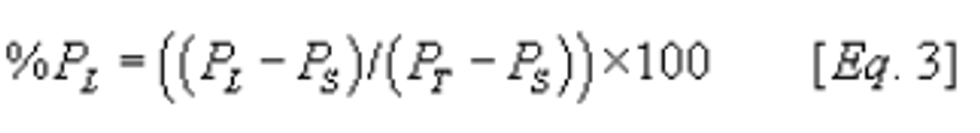

(4) Percent leaking pumps shall be determined by the following equation:

Where:

%PL = Percent leaking pumps

PL = Number of pumps found leaking as determined through monthly monitoring as required in paragraph (b)(1) of this section. Do not include results from inspection of unsafe-to-monitor pumps pursuant to paragraph (e)(6) of this section.

PS = Number of pumps leaking within 1 month of start-up during the current monitoring period.

PT = Total pumps in regulated material service, including those meeting the criteria in paragraphs (e)(1), (e)(2), (e)(3), and (e)(6) of this section.

(d) Leak repair. If a leak is detected pursuant to paragraph (b) of this section, then the leak shall be repaired using the procedures in §63.1024, as applicable, unless otherwise specified in paragraph (b)(5) of this section for leaks identified by visual indications of liquids dripping.

(e) Special provisions for pumps - (1) Dual mechanical seal pumps. Each pump equipped with a dual mechanical seal system that includes a barrier fluid system is exempt from the requirements of paragraph (b) of this section, provided the requirements specified in paragraphs (e)(1)(i) through (e)(1)(viii) of this section are met.

(i) The owner or operator determines, based on design considerations and operating experience, criteria applicable to the presence and frequency of drips and to the sensor that indicates failure of the seal system, the barrier fluid system, or both. The owner or operator shall keep records at the plant of the design criteria and an explanation of the design criteria; and any changes to these criteria and the reasons for the changes. This record must be available for review by an inspector.

(ii) Each dual mechanical seal system shall meet the requirements specified in paragraph (e)(1)(ii)(A), (e)(1)(ii)(B), or (e)(1)(ii)(C) of this section.

(A) Each dual mechanical seal system is operated with the barrier fluid at a pressure that is at all times (except periods of startup, shutdown, or malfunction) greater than the pump stuffing box pressure; or

(B) Equipped with a barrier fluid degassing reservoir that is routed to a process or fuel gas system or connected by a closed-vent system to a control device that complies with the requirements of either §63.1034 or §63.1021(b) of this part; or

(C) Equipped with a closed-loop system that purges the barrier fluid into a process stream.

(iii) The barrier fluid is not in light liquid service.

(iv) Each barrier fluid system is equipped with a sensor that will detect failure of the seal system, the barrier fluid system, or both.

(v) Each pump is checked by visual inspection each calendar week for indications of liquids dripping from the pump seal. The owner or operator shall document that the inspection was conducted and the date of the inspection. If there are indications of liquids dripping from the pump seal at the time of the weekly inspection, the owner or operator shall follow the procedure specified in paragraphs (e)(1)(v)(A) or (e)(1)(v)(B) of this section prior to the next required inspection.

(A) The owner or operator shall monitor the pump as specified in §63.1023(b) and, as applicable, §63.1023 (c), to determine if there is a leak of regulated material in the barrier fluid. If an instrument reading of 1,000 parts per million or greater is measured, a leak is detected and it shall be repaired using the procedures in §63.1024; or

(B) The owner or operator shall eliminate the visual indications of liquids dripping.

(vi) If indications of liquids dripping from the pump seal exceed the criteria established in paragraph (e)(1)(i) of this section, or if based on the criteria established in paragraph (e)(1)(i) of this section the sensor indicates failure of the seal system, the barrier fluid system, or both, a leak is detected.

(vii) Each sensor as described in paragraph (e)(1)(iv) of this section is observed daily or is equipped with an alarm unless the pump is located within the boundary of an unmanned plant site.

(viii) When a leak is detected pursuant to paragraph (e)(1)(vi) of this section, it shall be repaired as specified in §63.1024.

(2) No external shaft. Any pump that is designed with no externally actuated shaft penetrating the pump housing is exempt from the requirements of paragraph (b) of this section.

(3) Routed to a process or fuel gas system or equipped with a closed vent system. Any pump that is routed to a process or fuel gas system or equipped with a closed vent system capable of capturing and transporting leakage from the pump to a control device meeting the requirements of §63.1034 of this part or §63.1021(b) is exempt from the requirements of paragraph (b) of this section.

(4) Unmanned plant site. Any pump that is located within the boundary of an unmanned plant site is exempt from the weekly visual inspection requirement of paragraphs (b)(4) and (e)(1)(v) of this section, and the daily requirements of paragraph (e)(1)(vii) of this section, provided that each pump is visually inspected as often as practical and at least monthly.

(5) 90 percent exemption. If more than 90 percent of the pumps at a process unit or affected facility meet the criteria in either paragraph (e)(1) or (e)(2) of this section, the process unit or affected facility is exempt from the percent leaking calculation in paragraph (c) of this section.

(6) Unsafe-to-monitor pumps. Any pump that is designated, as described in §63.1022(c)(1), as an unsafe-to-monitor pump is exempt from the requirements of paragraph (b) of this section, the monitoring and inspection requirements of paragraphs (e)(1)(v) through (viii) of this section, and the owner or operator shall monitor and inspect the pump according to the written plan specified in §63.1022(c)(4).

[64 FR 34899, June 29, 1999, as amended at 64 FR 63706, Nov. 22, 1999]

§63.1027 Connectors in gas and vapor service and in light liquid service standards.

(a) Compliance schedule. The owner or operator shall monitor all connectors in each process unit initially for leaks by the later of either 12 months after the compliance date as specified in a referencing subpart or 12 months after initial startup. If all connectors in each process unit have been monitored for leaks prior to the compliance date specified in the referencing subpart, no initial monitoring is required provided either no process changes have been made since the monitoring or the owner or operator can determine that the results of the monitoring, with or without adjustments, reliably demonstrate compliance despite process changes. If required to monitor because of a process change, the owner or operator is required to monitor only those connectors involved in the process change.

(b) Leak detection. Except as allowed in §63.1021(b), §63.1036, §63.1037, or as specified in paragraph (e) of this section, the owner or operator shall monitor all connectors in gas and vapor and light liquid service as specified in paragraphs (a) and (b)(3) of this section.

(1) Monitoring method. The connectors shall be monitored to detect leaks by the method specified in §63.1023(b) and, as applicable, §63.1023(c).

(2) Instrument reading that defines a leak. If an instrument reading greater than or equal to 500 parts per million is measured, a leak is detected.

(3) Monitoring periods. The owner or operator shall perform monitoring, subsequent to the initial monitoring required in paragraph (a) of this section, as specified in paragraphs (b)(3)(i) through (b)(3)(iii) of this section, and shall comply with the requirements of paragraphs (b)(3)(iv) and (b)(3)(v) of this section. The required period in which monitoring must be conducted shall be determined from paragraphs (b)(3)(i) through (b)(3)(iii) of this section using the monitoring results from the preceding monitoring period. The percent leaking connectors shall be calculated as specified in paragraph (c) of this section.

(i) If the percent leaking connectors in the process unit was greater than or equal to 0.5 percent, then monitor within 12 months (1 year).

(ii) If the percent leaking connectors in the process unit was greater than or equal to 0.25 percent but less than 0.5 percent, then monitor within 4 years. An owner or operator may comply with the requirements of this paragraph by monitoring at least 40 percent of the connectors within 2 years of the start of the monitoring period, provided all connectors have been monitored by the end of the 4 year monitoring period.

(iii) If the percent leaking connectors in the process unit was less than 0.25 percent, then monitor as provided in paragraph (b)(3)(iii)(A) of this section and either paragraph (b)(3)(iii)(B) or (b)(3)(iii)(C) of this section, as appropriate.

(A) An owner or operator shall monitor at least 50 percent of the connectors within 4 years of the start of the monitoring period.

(B) If the percent leaking connectors calculated from the monitoring results in paragraph (b)(3)(iii)(A) of this section is greater than or equal to 0.35 percent of the monitored connectors, the owner or operator shall monitor as soon as practical, but within the next 6 months, all connectors that have not yet been monitored during the monitoring period. At the conclusion of monitoring, a new monitoring period shall be started pursuant to paragraph (b)(3) of this section, based on the percent leaking connectors of the total monitored connectors.

(C) If the percent leaking connectors calculated from the monitoring results in paragraph (b)(3)(iii)(A) of this section is less than 0.35 percent of the monitored connectors, the owner or operator shall monitor all connectors that have not yet been monitored within 8 years of the start of the monitoring period.

(iv) If, during the monitoring conducted pursuant to paragraph (b)(3)(i) through (b)(3)(iii) of this section, a connector is found to be leaking, it shall be re-monitored once within 90 days after repair to confirm that it is not leaking.

(v) The owner or operator shall keep a record of the start date and end date of each monitoring period under this section for each process unit.

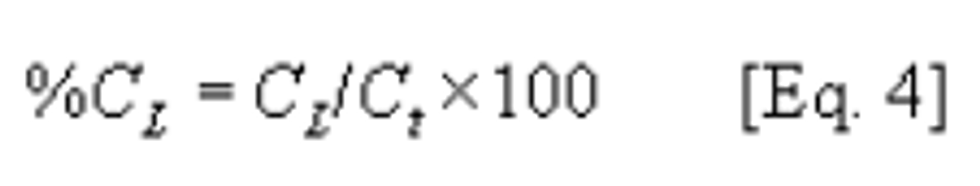

(c) Percent leaking connectors calculation. For use in determining the monitoring frequency, as specified in paragraphs (a) and (b)(3) of this section, the percent leaking connectors as used in paragraphs (a) and (b)(3) of this section shall be calculated by using equation number 4.

Where:

%CL = Percent leaking connectors as determined through periodic monitoring required in paragraphs (a) and (b)(3)(i) through (b)(3)(iii) of this section.

CL = Number of connectors measured at 500 parts per million or greater, by the method specified in §63.1023(b).

Ct = Total number of monitored connectors in the process unit or affected facility.

(d) Leak repair. If a leak is detected pursuant to paragraphs (a) and (b) of this section, then the leak shall be repaired using the procedures in §63.1024, as applicable.

(e) Special provisions for connectors - (1) Unsafe-to-monitor connectors. Any connector that is designated, as described in §63.1022(c)(1), as an unsafe-to-monitor connector is exempt from the requirements of paragraphs (a) and (b) of this section and the owner or operator shall monitor according to the written plan specified in §63.1022(c)(4).

(2) Inaccessible, ceramic, or ceramic-lined connectors. (i) Any connector that is inaccessible or that is ceramic or ceramic-lined (e.g., porcelain, glass, or glass-lined), is exempt from the monitoring requirements of paragraphs (a) and (b) of this section, from the leak repair requirements of paragraph (d) of this section, and from the recordkeeping and reporting requirements of §§63.1038 and 63.1039. An inaccessible connector is one that meets any of the provisions specified in paragraphs (e)(2)(i)(A) through (e)(2)(i)(F) of this section, as applicable.

(A) Buried;

(B) Insulated in a manner that prevents access to the connector by a monitor probe;

(C) Obstructed by equipment or piping that prevents access to the connector by a monitor probe;

(D) Unable to be reached from a wheeled scissor-lift or hydraulic-type scaffold that would allow access to connectors up to 7.6 meters (25 feet) above the ground.

(E) Inaccessible because it would require elevating the monitoring personnel more than 2 meters (7 feet) above a permanent support surface or would require the erection of scaffold;

(F) Not able to be accessed at any time in a safe manner to perform monitoring. Unsafe access includes, but is not limited to, the use of a wheeled scissor-lift on unstable or uneven terrain, the use of a motorized man-lift basket in areas where an ignition potential exists, or access would require near proximity to hazards such as electrical lines, or would risk damage to equipment.

(ii) If any inaccessible, ceramic or ceramic-lined connector is observed by visual, audible, olfactory, or other means to be leaking, the visual, audible, olfactory, or other indications of a leak to the atmosphere shall be eliminated as soon as practical.

§63.1028 Agitators in gas and vapor service and in light liquid service standards.

(a) Compliance schedule. The owner or operator shall comply with this section no later than the compliance dates specified in the referencing subpart.

(b) [Reserved]

(c) Leak detection - (1) Monitoring method. Each agitator seal shall be monitored monthly to detect leaks by the methods specified in §63.1023(b) and, as applicable, §63.1023(c), except as provided in §63.1021(b), §63.1036, §63.1037, or paragraph (e) of this section.

(2) Instrument reading that defines a leak. If an instrument reading equivalent of 10,000 parts per million or greater is measured, a leak is detected.

(3) Visual inspection. (i) Each agitator seal shall be checked by visual inspection each calendar week for indications of liquids dripping from the agitator seal. The owner or operator shall document that the inspection was conducted and the date of the inspection.

(ii) If there are indications of liquids dripping from the agitator seal, the owner or operator shall follow the procedures specified in paragraphs (c)(3)(ii)(A) or (c)(3)(ii)(B) of this section prior to the next required inspection.

(A) The owner or operator shall monitor the agitator seal as specified in §63.1023(b) and, as applicable, §63.1023(c), to determine if there is a leak of regulated material. If an instrument reading of 10,000 parts per million or greater is measured, a leak is detected, and it shall be repaired according to paragraph (d) of this section; or

(B) The owner or operator shall eliminate the indications of liquids dripping from the agitator seal.

(d) Leak repair. If a leak is detected, then the leak shall be repaired using the procedures in §63.1024.

(e) Special provisions for agitators - (1) Dual mechanical seal. Each agitator equipped with a dual mechanical seal system that includes a barrier fluid system is exempt from the requirements of paragraph (c) of this section, provided the requirements specified in paragraphs (e)(1)(i) through (e)(1)(vi) of this section are met.

(i) Each dual mechanical seal system shall meet the applicable requirements specified in paragraphs (e)(1)(i)(A), (e)(1)(i)(B), or (e)(1)(i)(C) of this section.

(A) Operated with the barrier fluid at a pressure that is at all times (except during periods of startup, shutdown, or malfunction) greater than the agitator stuffing box pressure; or

(B) Equipped with a barrier fluid degassing reservoir that is routed to a process or fuel gas system or connected by a closed-vent system to a control device that meets the requirements of either §63.1034 or §63.1021(b); or

(C) Equipped with a closed-loop system that purges the barrier fluid into a process stream.

(ii) The barrier fluid is not in light liquid service.

(iii) Each barrier fluid system is equipped with a sensor that will detect failure of the seal system, the barrier fluid system, or both.

(iv) Each agitator seal is checked by visual inspection each calendar week for indications of liquids dripping from the agitator seal. If there are indications of liquids dripping from the agitator seal at the time of the weekly inspection, the owner or operator shall follow the procedure specified in paragraphs (e)(1)(iv)(A) or (e)(1)(iv)(B) of this section prior to the next required inspection.

(A) The owner or operator shall monitor the agitator seal as specified in §63.1023(b) and, as applicable, §63.1023(c), to determine the presence of regulated material in the barrier fluid. If an instrument reading equivalent to or greater than 10,000 ppm is measured, a leak is detected and it shall be repaired using the procedures in §63.1024, or

(B) The owner or operator shall eliminate the visual indications of liquids dripping.

(v) Each sensor as described in paragraph (e)(1)(iii) of this section is observed daily or is equipped with an alarm unless the agitator seal is located within the boundary of an unmanned plant site.

(vi) The owner or operator of each dual mechanical seal system shall meet the requirements specified in paragraphs (e)(1)(vi)(A) and (e)(1)(vi)(B).

(A) The owner or operator shall determine, based on design considerations and operating experience, criteria that indicates failure of the seal system, the barrier fluid system, or both and applicable to the presence and frequency of drips. If indications of liquids dripping from the agitator seal exceed the criteria, or if, based on the criteria the sensor indicates failure of the seal system, the barrier fluid system, or both, a leak is detected and shall be repaired pursuant to §63.1024, as applicable.

(B) The owner or operator shall keep records of the design criteria and an explanation of the design criteria; and any changes to these criteria and the reasons for the changes.

(2) No external shaft. Any agitator that is designed with no externally actuated shaft penetrating the agitator housing is exempt from paragraph (c) of this section.

(3) Routed to a process or fuel gas system or equipped with a closed vent system. Any agitator that is routed to a process or fuel gas system that captures and transports leakage from the agitator to a control device meeting the requirements of either §63.1034 or §63.1021(b) is exempt from the requirements of paragraph (c) of this section.

(4) Unmanned plant site. Any agitator that is located within the boundary of an unmanned plant site is exempt from the weekly visual inspection requirement of paragraphs (c)(3) and (e)(1)(iv) of this section, and the daily requirements of paragraph (e)(1)(v) of this section, provided that each agitator is visually inspected as often as practical and at least monthly.