['Water Programs']

['Water Quality']

05/05/2022

...

Authority:Secs. 301, 304, 306, 307, and 501, Pub. L. 92-500, 86 Stat. 816, Pub. L. 95-217, 91 Stat. 156, Pub. L. 100-4, 101 Stat. 7 (33 U.S.C. 1311, 1314, 1316, 1317, and 1361).

Subpart A - General

§414.10 General definitions.

As used in this part:

(a) Except as provided in this regulation, the general definitions, abbreviations and methods of analysis set forth in part 401 of this chapter shall apply to this part.

(b) Pretreatment control authority means:

(1) The POTW if the POTW's submission for its pretreatment program has been approved in accordance with the requirements of 40 CFR 403.11, or

(2) The Approval Authority if the submission has not been approved.

(c) Priority pollutants means the toxic pollutants listed in 40 CFR 401.15.

§414.11 Applicability.

(a) The provisions of this part are applicable to process wastewater discharges from all establishments or portions of establishments that manufacture the organic chemicals, plastics, and synthetic fibers (OCPSF) products or product groups covered by subparts B through H of this regulation and are included within the following U.S. Department of Commerce Bureau of the Census Standard Industrial Classification (SIC) major groups:

(1) SIC 2821 - Plastic Materials, Synthetic Resins, and Nonvulcanizable Elastomers,

(2) SIC 2823 - Cellulosic Man-Made Fibers,

(3) SIC 2824 - Synthetic Organic Fibers, Except Cellulosic,

(4) SIC 2865 - Cyclic Crudes and Intermediates, Dyes, and Organic Pigments,

(5) SIC 2869 - Industrial Organic Chemicals, Not Elsewhere Classified.

(b) The provisions of this part are applicable to wastewater discharges from OCPSF research and development, pilot plant, technical service and laboratory bench scale operations if such operations are conducted in conjunction with and related to existing OCPSF manufacturing activities at the plant site.

(c) Notwithstanding paragraph (a) of this section, the provisions of this part are not applicable to discharges resulting from the manufacture of OCPSF products if the products are included in the following SIC subgroups and have in the past been reported by the establishment under these subgroups and not under the SIC groups listed in paragraph (a) of this section:

(1) SIC 2843085 - bulk surface active agents;

(2) SIC 28914 - synthetic resin and rubber adhesives;

(3) Chemicals and Chemical Preparations, not Elsewhere Classified:

(i) SIC 2899568 - sizes, all types

(ii) SIC 2899597 - other industrial chemical specialties, including fluxes, plastic wood preparations, and embalming fluids;

(4) SIC 2911058 - aromatic hydrocarbons manufactured from purchased refinery products; and

(5) SIC 2911632 - aliphatic hydrocarbons manufactured from purchased refinery products.

(d) Notwithstanding paragraph (a) of this section, the provisions of this part are not applicable to any discharges for which a different set of previously promulgated effluent limitations guidelines and standards in this subchapter apply, unless the facility reports OCPSF products under SIC codes 2865, 2869, or 2821, and the facility's OCPSF wastewaters are treated in a separate treatment system or discharged separately to a publicly owned treatment works.

(e) The provisions of this part do not apply to any process wastewater discharges from the manufacture of organic chemical compounds solely by extraction from plant and animal raw materials or by fermentation processes.

(f) Discharges of chromium, copper, lead, nickel, and zinc in “complexed metal-bearing waste streams,” listed in appendix B of this part, are not subject to the requirements of this part.

(g) Non-amenable cyanide. Discharges of cyanide in “cyanide-bearing waste streams” (listed in appendix A to this part) are not subject to the cyanide limitations and standards of this part if the permit writer or control authority determines that the cyanide limitations and standards are not achievable due to elevated levels of non-amenable cyanide (i.e., cyanide that is not oxidized by chlorine treatment) that result from the unavoidable complexing of cyanide at the process source of the cyanide-bearing waste stream and establishes an alternative total cyanide or amenable cyanide limitation that reflects the best available technology economically achievable. The determination must be based upon a review of relevant engineering, production, and sampling and analysis information, including measurements of both total and amenable cyanide in the waste stream. An analysis of the extent of complexing in the waste stream, based on the foregoing information, and its impact on cyanide treatability shall be set forth in writing and, for direct dischargers, be contained in the fact sheet required by 40 CFR 124.8.

(h) Allowances for non-metal-bearing waste streams. Discharge limitations for chromium, copper, lead, nickel, and zinc or discharge standards for lead and zinc may be established for waste streams not listed in appendix A of this part and not otherwise determined to be “metal-bearing waste streams” if the permit writer or control authority determines that the wastewater metals contamination is due to background levels that are not reasonably avoidable from sources such as intake water, corrosion of construction materials or contamination of raw materials. The determination must be based upon a review of relevant plant operating conditions, process chemistry, engineering, and sampling and analysis information. An analysis of the sources and levels of the metals, based on the foregoing information, shall be set forth in writing; for direct dischargers, the analysis shall be contained in the fact sheet required by 40 CFR 124.8. For direct dischargers, the permit writer may establish limitations for chromium, copper, lead, nickel, and zinc for non-“metal-bearing waste streams” between the lowest level which the permit writer determines based on best professional judgment can be reliably measured and the concentrations of such metals present in the wastestreams, but not to exceed the applicable limitations contained in §§414.91 and 414.101. (For zinc, the applicable limitations which may not be exceeded are those appearing in the tables in §§414.91 and 414.101, not the alternative limitations for rayon fiber manufacture by the viscose process and the acrylic fiber manufacture by the zinc chloride/solvent process set forth in footnote 2 to each of these tables.) For indirect dischargers, the control authority may establish standards for lead and zinc for non-“metal-bearing waste streams” between the lowest level which the control authority determines based on best professional judgment can be reliably measured and the concentration of such metals present in the wastestreams, but not to exceed the applicable standards contained in §§414.25, 414.35, 414.45, 414.55, 414.65, 414.75, and 414.85. (For zinc, the applicable standards which may not be exceeded are those appearing in the tables in the above referenced sections, not the alternative standards for rayon filber manufacture by the viscose process set forth in footnote 2 to the table in §414.25, or the alternative standards for acrylic fiber manufacture by the zinc chloride/solvent process set forth in footnote 2 to the table in §414.35.) The limitations and standards for individual dischargers shall be set on a mass basis by multiplying the concentration allowance established by the permit writer or control authority by the process wastewater flow from the individual wastestreams for which incidental metals have been found to be present.

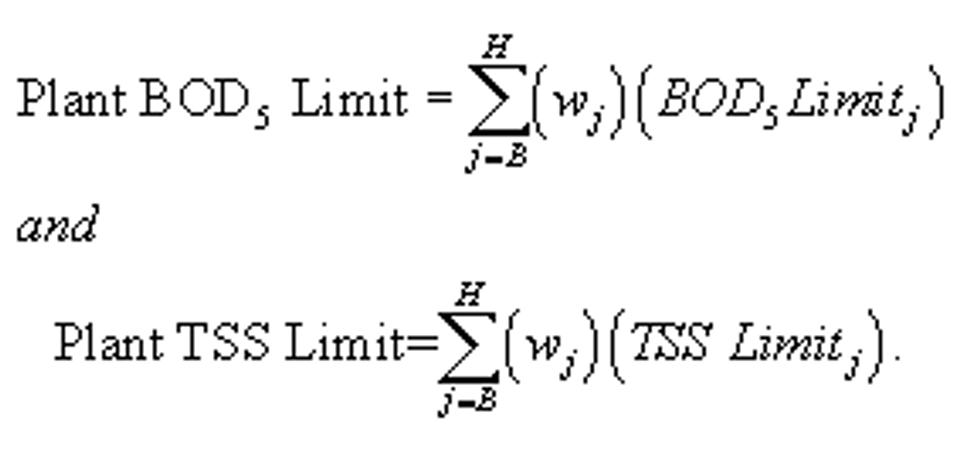

(i) BOD5 and TSS limitations for plants with production in two or more subcategories. Any existing or new source direct discharge point source subject to two or more of subparts B through H must achieve BOD5 and TSS discharges not exceeding the quantity (mass) determined by multiplying the total OCPSF process wastewater flow subject to subparts B through H times the following “OCPSF production-proportioned concentration”: For a specific plant, let wj be the proportion of the plant's total OCPSF production in subcategory j. Then the plant-specific production-proportioned concentration limitations are given by:

The “BOD5 Limitj” and “TSS Limitj” are the respective subcategorical BOD5 and TSS Maximum for Any One Day or Maximum for Monthly Average limitations.

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41843, Sept. 11, 1992]

§414.12 Compliance date for pretreatment standards for existing sources (PSES).

All dischargers subject to PSES in this part must comply with the standards by no later than three years after date of promulgation in the Federal Register.

Subpart B - Rayon Fibers

§414.20 Applicability; description of the rayon fibers subcategory.

The provisions of this subpart are applicable to process wastewater discharges resulting from the manufacture of rayon fiber by the viscose process only.

§414.21 Effluent limitations representing the degree of effluent reduction attainable by the application of the best practicable control technology currently available (BPT).

Except as provided in 40 CFR 125.30 through 125.32, and in 40 CFR 414.11(i) for point sources with production in two or more subcategories, any existing point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentration listed in the following table.

| Effluent characteristics | BPT effluent limitations 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 64 | 24 |

| TSS | 130 | 40 |

| pH | ( 2) | ( 2) |

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.22 Effluent limitations representing the degree of effluent reduction attainable by the application of the best conventional pollutant control technology (BCT). [Reserved]

§414.23 Effluent limitations representing the degree of effluent reduction attainable by the application of the best available technology economically achievable (BAT).

(a) The Agency has determined that for existing point sources whose total OCPSF production defined by §414.11 is less than or equal to five (5) million pounds of OCPSF products per year, the BPT level of treatment is the best available technology economically achievable. Accordingly, the Agency is not promulgating more stringent BAT limitations for these point sources.

(b) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part.

(c) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part.

§414.24 New source performance standards (NSPS).

(a) Any new source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

(b) Any new source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

| Effluent characteristics | NSPS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 64 | 24 |

| TSS | 130 | 40 |

| pH | ( 2) | ( 2) |

§414.25 Pretreatment standards for existing sources (PSES).

Except as provided in 40 CFR 403.7 and 403.13, any existing source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

§414.26 Pretreatment standards for new sources (PSNS).

Except as provided in 40 CFR 403.7 any new source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §411.111.

[58 FR 36892, July 9, 1993]

Subpart C - Other Fibers

§414.30 Applicability; description of the other fibers subcategory.

The provisions of this subpart are applicable to the process wastewater discharges resulting from the manufacture of products classified under SIC 2823 cellulosic man-made fibers, except Rayon, and SIC 2824 synthetic organic fibers including those fibers and fiber groups listed below. Product groups are indicated with an asterisk (*).

*Acrylic Fibers (85% Polyacrylonitrile)

*Cellulose Acetate Fibers

*Fluorocarbon (Teflon) Fibers

*Modacrylic Fibers

*Nylon 6 Fibers

Nylon 6 Monofilament

*Nylon 66 Fibers

Nylon 66 Monofilament

*Polyamide Fibers (Quiana)

*Polyaramid (Kevlar) Resin-Fibers

*Polyaramid (Nomex) Resin-Fibers

*Polyester Fibers

*Polyethylene Fibers

*Polypropylene Fibers

*Polyurethane Fibers (Spandex)

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.31 Effluent limitations representing the degree of effluent reduction attainable by the application of the best practicable control technology currently available (BPT).

Except as provided in 40 CFR 125.30 through 125.32, and in 40 CFR 414.11(i) for point sources with production in two or more subcategories, any existing point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentration listed in the following table.

| Effluent characteristics | BPT effluent limitations 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 48 | 18 |

| TSS | 115 | 36 |

| pH | ( 2) | ( 2) |

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.32 Effluent limitations representing the degree of effluent reduction attainable by the application of the best conventional pollutant control technology (BCT). [Reserved]

§414.33 Effluent limitations representing the degree of effluent reduction attainable by the application of the best available technology economically achievable (BAT).

(a) The Agency has determined that for existing point sources whose total OCPSF production defined by §414.11 is less than or equal to five (5) million pounds of OCPSF products per year, the BPT level of treatment is the best available technology economically achievable. Accordingly, the Agency is not promulgating more stringent BAT limitations for these point sources.

(b) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part.

(c) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part.

§414.34 New source performance standards (NSPS).

(a) Any new source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

(b) Any new source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

| Effluent characteristics | NSPS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 48 | 18 |

| TSS | 115 | 36 |

| pH | ( 2) | ( 2) |

§414.35 Pretreatment standards for existing sources (PSES).

Except as provided in 40 CFR 403.7 and 403.13, any existing source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

§414.36 Pretreatment standards for new sources (PSNS).

Except as provided in 40 CFR 403.7 any new source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

Subpart D - Thermoplastic Resins

§414.40 Applicability; description of the thermoplastic resins subcategory.

The provisions of this subpart are applicable to the process wastewater discharges resulting from the manufacture of the products classified under SIC 28213 thermoplastic resins including those resins and resin groups listed below. Product groups are indicated with an asterisk (*).

*Abietic Acid - Derivatives

*ABS Resins

*ABS-SAN Resins

*Acrylate-Methacrylate Latexes

*Acrylic Latex

*Acrylic Resins

*Cellulose Acetate Butyrates

Cellulose Acetate Resin

*Cellulose Acetates

*Cellulose Acetates Propionates

Cellulose Nitrate

*Ethylene-Methacrylic Acid Copolymers

*Ethylene-Vinyl Acetate Copolymers

*Fatty Acid Resins

*Fluorocarbon Polymers

Nylon 11 Resin

*Nylon 6-66 Copolymers

*Nylon 6 - Nylon 11 Blends

Nylon 6 Resin

Nylon 612 Resin

Nylon 66 Resin

*Nylons

*Petroleum Hydrocarbon Resins

*Polyvinyl Pyrrolidone - Copolymers

*Poly(Alpha)Olefins

Polyacrylic Acid

*Polyamides

*Polyarylamides

Polybutadiene

*Polybutenes

Polybutenyl Succinic Anhydride

*Polycarbonates

*Polyester Resins

*Polyester Resins, Polybutylene Terephthalate

*Polyester Resins, Polyoxybenzoate

Polyethylene

*Polyethylene - Ethyl Acrylate Resins

*Polyethylene - Polyvinyl Acetate Copolymers

Polyethylene Resin (HDPE)

Polyethylene Resin (LPDE)

Polyethylene Resin, Scrap

Polyethylene Resin, Wax (Low M.W.)

Polyethylene Resin, Latex

Polyethylene Resins

*Polyethylene Resins, Compounded

*Polyethylene, Chlorinated

*Polyimides

*Polypropylene Resins

Polystyrene (Crystal)

Polystyrene (Crystal) Modified

*Polystyrene - Copolymers

*Polystyrene - Acrylic Latexes

Polystyrene Impact Resins

Polystyrene Latex

Polystyrene, Expandable

Polystyrene, Expanded

*Polysulfone Resins

Polyvinyl Acetate

*Polyvinyl Acetate - PVC Copolymers

*Polyvinyl Acetate Copolymers

*Polyvinyl Acetate Resins

Polyvinyl Alcohol Resin

Polyvinyl Chloride

Polyvinyl Chloride, Chlorinated

*Polyvinyl Ether-Maleic Anhydride

*Polyvinyl Formal Resins

*Polyvinylacetate - Methacrylic Copolymers

*Polyvinylacetate Acrylic Copolymers

*Polyvinylacetate-2-Ethylhexylacrylate Copolymers

Polyvinylidene Chloride

*Polyvinylidene Chloride Copolymers

*Polyvinylidene-Vinyl Chloride Resins

*PVC Copolymers, Acrylates (Latex)

*PVC Copolymers, Ethylene-Vinyl Chloride

*Rosin Derivative Resins

*Rosin Modified Resins

*Rosin Resins

*SAN Resins

*Silicones: Silicone Resins

*Silicones: Silicone Rubbers

*Styrene Maleic Anhydride Resins

Styrene Polymeric Residue

*Styrene-Acrylic Copolymer Resins

*Styrene-Acrylonitrile-Acrylates Copolymers

*Styrene-Butadiene Resins

*Styrene-Butadiene Resins (<50% Butadiene)

*Styrene-Butadiene Resins (latex)

*Styrene-Divinyl Benzene Resins (Ion Exchange)

*Styrene-Methacrylate Terpolymer Resins

*Styrene-Methyl Methacrylate Copolymers

*Styrene, Butadiene, Vinyl Toluene Terpolymers

*Sulfonated Styrene-Maleic Anhydride Resins

*Unsaturated Polyester Resins

*Vinyl Toluene Resins

*Vinyl Toluene-Acrylate Resins

*Vinyl Toluene-Butadiene Resins

*Vinyl Toluene-Methacrylate Resins

*Vinylacetate-N-Butylacrylate Copolymers

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.41 Effluent limitations representing the degree of effluent reduction attainable by the application of the best practicable control technology currently available (BPT).

Except as provided in 40 CFR 125.30 through 125.32, and in 40 CFR 414.11(i) for point sources with production in two or more subcategories, any existing point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentration listed in the following table.

| Effluent characteristics | BPT Effluent Limitations 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 64 | 24 |

| TSS | 130 | 40 |

| pH | ( 2) | ( 2) |

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.42 Effluent limitations representing the degree of effluent reduction attainable by the application of the best conventional pollutant control technology (BCT). [Reserved]

§414.43 Effluent limitations representing the degree of effluent reduction attainable by the application of the best available technology economically achievable (BAT).

(a) The Agency has determined that for existing point sources whose total OCPSF production defined by §414.11 is less than or equal to five (5) million pounds of OCPSF products per year, the BPT level of treatment is the best available technology economically achievable. Accordingly, the Agency is not promulgating more stringent BAT limitations for these point sources.

(b) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part.

(c) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part.

§414.44 New source performance standards (NSPS).

(a) Any new source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

(b) Any new source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

| Effluent characteristics | NSPS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 64 | 24 |

| TSS | 130 | 40 |

| pH | ( 2) | ( 2) |

§414.45 Pretreatment standards for existing sources (PSES).

Except as provided in 40 CFR 403.7 and 403.13, any existing source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

§414.46 Pretreatment standards for new sources (PSNS).

Except as provided in 40 CFR 403.7 any new source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

Subpart E - Thermosetting Resins

§414.50 Applicability; description of the thermosetting resins subcategory.

The provisions of this subpart are applicable to the process wastewater discharges resulting from the manufacture of the products classified under SIC 28214 thermosetting resins including those resins and resin groups listed below. Product groups are indicated with an asterisk (*).

*Alkyd Resins

Dicyanodiamide Resin

*Epoxy Resins

*Fumaric Acid Polyesters

*Furan Resins

Glyoxal-Urea Formaldehyde Textile Resin

*Ketone-Formaldehyde Resins

*Melamine Resins

*Phenolic Resins

*Polyacetal Resins

Polyacrylamide

*Polyurethane Prepolymers

*Polyurethane Resins

*Urea Formaldehyde Resins

*Urea Resins

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.51 Effluent limitations representing the degree of effluent reduction attainable by the application of the best practicable control technology currently available (BPT).

Except as provided in 40 CFR 125.30 through 125.32, and in 40 CFR 414.11(i) for point sources with production in two or more subcategories, any existing point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentration listed in the following table.

| Effluent characteristics | BPT effluent limitations 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 163 | 61 |

| TSS | 216 | 67 |

| pH | ( 2) | ( 2) |

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.52 Effluent limitations representing the degree of effluent reduction attainable by the application of the best conventional pollutant control technology (BCT). [Reserved]

§414.53 Effluent limitations representing the degree of effluent reduction attainable by the application of the best available technology economically achievable (BAT).

(a) The Agency has determined that for existing point sources whose total OCPSF production defined by §414.11 is less than or equal to five (5) million pounds of OCPSF products per year, the BPT level of treatment is the best available technology economically achievable. Accordingly, the Agency is not promulgating more stringent BAT limitations for these point sources.

(b) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part.

(c) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part.

§414.54 New source performance standards (NSPS).

(a) Any new source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

(b) Any new source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

| Effluent characteristics | NSPS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 163 | 61 |

| TSS | 216 | 67 |

| pH | ( 2) | ( 2) |

§414.55 Pretreatment standards for existing sources (PSES).

Except as provided in 40 CFR 403.7 and 403.13, any existing source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

§414.56 Pretreatment standards for new sources (PSNS).

Except as provided in 40 CFR 403.7 any new source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

Subpart F - Commodity Organic Chemicals

§414.60 Applicability; description of the commodity organic chemicals subcategory.

The provisions of this subpart are applicable to the process wastewater discharges resulting from the manufacture of the following SIC 2865 and 2869 commodity organic chemicals and commodity organic chemical groups. Product groups are indicated with an asterisk (*).

(a) Aliphatic Organic Chemicals

Acetaldehyde

Acetic Acid

Acetic Anhydride

Acetone

Acrylonitrile

Adipic Acid

*Butylenes (Butenes)

Cyclohexane

Ethanol

Ethylene

Ethylene Glycol

Ethylene Oxide

Formaldehyde

Isopropanol

Methanol

Polyoxypropylene Glycol

Propylene

Propylene Oxide

Vinyl Acetate

1,2-Dichloroethane

1,3-Butadiene

(b) Aromatic Organic Chemicals

Benzene

Cumene

Dimethyl Terephthalate

Ethylbenzene

m-Xylene (impure)

p-Xylene

Phenol

*Pitch Tar Residues

*Pyrolysis Gasolines

Styrene

Terephthalic Acid

Toluene

*Xylenes, Mixed

o-Xylene

(c) Halogenated Organic Chemicals

Vinyl Chloride

§414.61 Effluent limitations representing the degree of effluent reduction attainable by the application of the best practicable control technology currently available (BPT).

Except as provided in 40 CFR 125.30 through 125.32, and in 40 CFR 414.11(i) for point sources with production in two or more subcategories, any existing point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentration listed in the following table.

| Effluent characteristics | BPT Effluent limitations 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 80 | 30 |

| TSS | 149 | 46 |

| pH | ( 2) | ( 2) |

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.62 Effluent limitations representing the degree of effluent reduction attainable by the application of the best conventional pollutant control technology (BCT). [Reserved]

§414.63 Effluent limitations representing the degree of effluent reduction attainable by the application of the best available technology economically achievable (BAT).

(a) The Agency has determined that for existing point sources whose total OCPSF production defined by §414.11 is less than or equal to five (5) million pounds of OCPSF products per year, the BPT level of treatment is the best available technology economically achievable. Accordingly, the Agency is not promulgating more stringent BAT limitations for these point sources.

(b) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part.

(c) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part.

§414.64 New source performance standards (NSPS).

(a) Any new source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

(b) Any new source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

| Effluent characteristics | NSPS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 80 | 30 |

| TSS | 149 | 46 |

| pH | ( 2) | ( 2) |

§414.65 Pretreatment standards for existing sources (PSES).

Except as provided in 40 CFR 403.7 and 403.13, any existing source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

§414.66 Pretreatment standards for new sources (PSNS).

Except as provided in 40 CFR 403.7 any new source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

Subpart G - Bulk Organic Chemicals

§414.70 Applicability; description of the bulk organic chemicals subcategory.

The provisions of this subpart are applicable to the process wastewater discharges resulting from the manufacture of the following SIC 2865 and 2869 bulk organic chemicals and bulk organic chemical groups. Product groups are indicated with an asterisk (*).

(a) Aliphatic Organic Chemicals

*Acetic Acid Esters

*Acetic Acid Salts

Acetone Cyanohydrin

Acetylene

Acrylic Acid

*Acrylic Acid Esters

*Alkoxy Alkanols

*Alkylates

*Alpha-Olefins

Butane (all forms)

*C-4 Hydrocarbons (Unsaturated)

Calcium Stearate

Caprolactam

Carboxymethyl Cellulose

Cellulose Acetate Butyrates

*Cellulose Ethers

Cumene Hydroperoxide

Cyclohexanol

Cyclohexanol, Cyclohexanone (Mixed)

Cyclohexanone

Cyclohexene

*C12-C18 Primary Alcohols

*C5 Concentrates

*C9 Concentrates

Decanol

Diacetone Alcohol

*Dicarboxylic Acids - Salts

Diethyl Ether

Diethylene Glycol

Diethylene Glycol Diethyl Ether

Diethylene Glycol Dimethyl Ether

Diethylene Glycol Monoethyl Ether

Diethylene Glycol Monomethyl Ether

*Dimer Acids

Dioxane

Ethane

Ethylene Glycol Monophenyl Ether

*Ethoxylates, Misc.

Ethylene Glycol Dimethyl Ether

Ethylene Glycol Monobutyl Ether

Ethylene Glycol Monoethyl Ether

Ethylene Glycol Monomethyl Ether

Glycerine (Synthetic)

Glyoxal

Hexane

*Hexanes and Other C6 Hydrocarbons

Isobutanol

Isobutylene

Isobutyraldehyde

Isophorone

Isophthalic Acid

Isoprene

Isopropyl Acetate

Ligninsulfonic Acid, Calcium Salt

Maleic Anhydride

Methacrylic Acid

*Methacrylic Acid Esters

Methane

Methyl Ethyl Ketone

Methyl Methacrylate

Methyl Tert-Butyl Ether

Methylisobutyl Ketone

*n-Alkanes

n-Butyl Alcohol

n-Butylacetate

n-Butyraldehyde

n-Butyric Acid

n-Butyric Anhydride

*n-Paraffins

n-Propyl Acetate

n-Propyl Alcohol

Nitrilotriacetic Acid

Nylon Salt

Oxalic Acid

*Oxo Aldehydes - Alcohols

Pentaerythritol

Pentane

*Pentenes

*Petroleum Sulfonates

Pine Oil

Polyoxybutylene Glycol

Polyoxyethylene Glycol

Propane

Propionaldehyde

Propionic Acid

Propylene Glycol

Sec-Butyl Alcohol

Sodium Formate

Sorbitol

Stearic Acid, Calcium Salt (Wax)

Tert-Butyl Alcohol

1-Butene

1-Pentene

1,4-Butanediol

Isobutyl Acetate

2-Butene (Cis and Trans)

2-Ethyl Hexanol

2-Ethylbutyraldehyde

2,2,4-Trimethyl-1,3-Pentanediol

(b) Amine and Amide Organic Chemicals

2,4-Diaminotoluene

*Alkyl Amines

Aniline

Caprolactam, Aqueous Concentrate

Diethanolamine

Diphenylamine

*Ethanolamines

Ethylamine

Ethylenediamine

Ethylenediaminetetracetic Acid

*Fatty Amines

Hexamethylene Diamine

Isopropylamine

m-Toluidine

Melamine

Melamine Crystal

*Methylamines

Methylene Dianiline

n-Butylamine

N,N-Diethylaniline

N,N-Dimethylformamide

*Nitroanilines

Polymeric Methylene Dianiline

Sec-Butylamine

Tert-Butylamine

Toluenediamine (Mixture)

*Toluidines

o-Phenylenediamine

2,6-Dimethylaniline

4-(N-Hydroxyethylethylamino)-2-Hydroxyethyl Analine

4,4?-Methylenebis (N,N?-dimethyl)-aniline

4,4?Methylenedianiline

(c) Aromatic Organic Chemicals

Alpha-Methylstyrene

*Alkyl Benzenes

*Alkyl Phenols

*Alkylbenzene Sulfonic Acids, Salts

Aminobenzoic Acid (Meta and Para)

Beta-Naphthalene Sulfonic Acid

Benzenedisulfonic Acid

Benzoic Acid

Bis(2-Ethylhexyl)Phthalate

Bisphenol A

BTX-Benzene, Toluene, Xylene (Mixed)

Butyl Octyl Phthalate

Coal Tar

*Coal Tar Products (Misc.)

Creosote

*Cresols, Mixed

Cyanuric Acid

*Cyclic Aromatic Sulfonates

Dibutyl Phthalate

Diisobutyl Phthalate

Diisodecyl Phthalate

Diisooctyl Phthalate

Dimethyl Phthalate

Dinitrotoluene (Mixed)

Ditridecyl Phthalate

m-Cresol

Metanilic Acid

Methylenediphenyldiisocyanate

Naphthalene

*Naphthas, Solvent

Nitrobenzene

Nitrotoluene

Nonylphenol

p-Cresol

Phthalic Acid

Phthalic Anhydride

*Tars - Pitches

Tert-Butylphenol

*Toluene Diisocyanates (Mixture)

Trimellitic Acid

o-Cresol

1-Tetralol, 1-Tetralone Mix

2,4-Dinitrotoluene

2,6-Dinitrotoluene

(d) Halogenated Organic Chemicals

1,4-Phenylenediamine Dihydrochloride

Allyl Chloride

Benzyl Chloride

Carbon Tetrachloride

*Chlorinated Paraffins, 35-64 PCT, Chlorine

Chlorobenzene

*Chlorobenzenes (Mixed)

Chlorodifluoroethane

Chloroform

*Chloromethanes

2-Chloro-5-Methylphenol (6-chloro-m-cresol)

*Chlorophenols

Chloroprene

Cyanogen Chloride

Cyanuric Chloride

Dichloropropane

Epichlorohydrin

Ethyl Chloride

*Fluorocarbons (Freons)

Methyl Chloride

Methylene Chloride

Pentachlorophenol

Phosgene

Tetrachloroethylene

Trichloroethylene

Trichlorofluoromethane

Vinylidene Chloride

1,1-Dichloroethane

1,1,1-Trichloroethane

2,4-Dichlorophenol

(e) Other Organic Chemicals

Adiponitrile

Carbon Disulfide

Fatty Nitriles

*Organo-Tin Compounds

*Phosphate Esters

Tetraethyl Lead

Tetramethyl Lead

*Urethane Prepolymers

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.71 Effluent limitations representing the degree of effluent reduction attainable by the application of the best practicable control technology currently available (BPT).

Except as provided in 40 CFR 125.30 through 125.32, and in 40 CFR 414.11(i) for point sources with production in two or more subcategories, any existing point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentration listed in the following table.

| Effluent characteristics | BPT Effluent limitations 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 92 | 34 |

| TSS | 159 | 49 |

| pH | ( 2) | ( 2) |

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.72 Effluent limitations representing the degree of effluent reduction attainable by the application of the best conventional pollutant control technology (BCT). [Reserved]

§414.73 Effluent limitations representing the degree of effluent reduction attainable by the application of the best available technology economically achievable (BAT).

(a) The Agency has determined that for existing point sources whose total OCPSF production defined by §414.11 is less than or equal to five (5) million pounds of OCPSF products per year, the BPT level of treatment is the best available technology economically achievable. Accordingly, the Agency is not promulgating more stringent BAT limitations for these point sources.

(b) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part.

(c) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part.

§414.74 New source performance standards (NSPS).

(a) Any new source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

(b) Any new source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

| Effluent characteristics | NSPS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 92 | 34 |

| TSS | 159 | 49 |

| pH | ( 2) | ( 2) |

§414.75 Pretreatment standards for existing sources (PSES).

Except as provided in 40 CFR 403.7 and 403.13, any existing source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

§414.76 Pretreatment standards for new sources (PSNS).

Except as provided in 40 CFR 403.7 any new source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

Subpart H - Specialty Organic Chemicals

§414.80 Applicability; description of the specialty organic chemicals subcategory.

The provisions of this subpart are applicable to the process wastewater discharges resulting from the manufacture of all SIC 2865 and 2869 organic chemicals and organic chemical groups which are not defined as commodity or bulk organic chemicals in §§414.60 and 414.70, respectively.

§414.81 Effluent limitations representing the degree of effluent reduction attainable by the application of the best practicable control technology currently available (BPT).

Except as provided in 40 CFR 125.30 through 125.32, and in 40 CFR 414.11(i) for point sources with production in two or more subcategories, any existing point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentration listed in the following table.

| Effluent characteristics | BPT effluent limitations 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 120 | 45 |

| TSS | 183 | 57 |

| pH | ( 2) | ( 2) |

[52 FR 42568, Nov. 5, 1987, as amended at 57 FR 41844, Sept. 11, 1992]

§414.82 Effluent limitations representing the degree of effluent reduction attainable by the application of the best conventional pollutant control technology (BCT). [Reserved]

§414.83 Effluent limitations representing the degree of effluent reduction attainable by the application of the best available technology economically achievable (BAT).

(a) The Agency has determined that for existing point sources whose total OCPSF production defined by §414.11 is less than or equal to five (5) million pounds of OCPSF products per year, the BPT level of treatment is the best available technology economically achievable. Accordingly, the Agency is not promulgating more stringent BAT limitations for these point sources.

(b) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.91 of this part.

(c) Except as provided in paragraph (a) of this section and in 40 CFR 125.30 through 125.32, any existing point source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part.

§414.84 New source performance standards (NSPS).

(a) Any new source that uses end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.9 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

(b) Any new source that does not use end-of-pipe biological treatment and is subject to this subpart must achieve discharges in accordance with §414.101 of this part, and also must not exceed the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

| Effluent characteristics | NSPS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units except pH are milligrams per liter. 2 Within the range of 6.0 to 9.0 at all times. | ||

| BOD5 | 120 | 45 |

| TSS | 183 | 57 |

| pH | ( 2) | ( 2) |

§414.85 Pretreatment standards for existing sources (PSES).

Except as provided in 40 CFR 403.7 and 403.13, any existing source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

§414.86 Pretreatment standards for new sources (PSNS).

Except as provided in 40 CFR 403.7 any new source subject to this subpart which introduces pollutants into a publicly owned treatment works must comply with 40 CFR part 403 and achieve discharges in accordance with §414.111.

[58 FR 36892, July 9, 1993]

Subpart I - Direct Discharge Point Sources That Use End-of-Pipe Biological Treatment

§414.90 Applicability; description of the subcategory of direct discharge point sources that use end-of-pipe biological treatment.

The provisions of this subpart are applicable to the process wastewater discharges resulting from the manufacture of the OCPSF products and product groups defined by §414.11 from any point source that uses end-of-pipe biological treatment or installs end-of-pipe biological treatment to comply with BPT effluent limitations.

§414.91 Toxic pollutant effluent limitations and standards for direct discharge point sources that use end-of-pipe biological treatment.

(a) Any point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentrations in the following table.

(b) In the case of chromium, copper, lead, nickel, zinc, and total cyanide, the discharge quantity (mass) shall be determined by multiplying the concentrations listed in the following table for these pollutants times the flow from metal-bearing waste streams for the metals and times the flow from cyanide bearing waste streams for total cyanide. The metal-bearing waste streams and cyanide-bearing waste streams are defined as those waste streams listed in appendix A of this part, plus any additional OCPSF process wastewater streams identified by the permitting authority on a case-by-case basis as metal or cyanide bearing based upon a determination that such streams contain significant amounts of the pollutants identified above. Any such streams designated as metal or cyanide bearing must be treated independently of other metal or cyanide bearing waste streams unless the permitting authority determines that the combination of such streams, prior to treatment, with the appendix A waste streams will result in substantial reduction of these pollutants. This determination must be based upon a review of relevant engineering, production, and sampling and analysis information.

| Effluent characteristics | Effluent limitations BAT and NSPS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for any monthly average | |

| 1 All units are micrograms per liter. 2 Total Zinc for Rayon Fiber Manufacture that uses the viscose process and Acrylic Fiber Manufacture that uses the zinc chloride/solvent process is 6,796 µg/l and 3,325 µg/l for maximum for any one day and maximum for monthly average, respectively. | ||

| Acenaphthene | 59 | 22 |

| Acenaphthylene | 59 | 22 |

| Acrylonitrile | 242 | 96 |

| Anthracene | 59 | 22 |

| Benzene | 136 | 37 |

| Benzo(a)anthracene | 59 | 22 |

| 3,4-Benzofluoranthene | 61 | 23 |

| Benzo(k)fluoranthene | 59 | 22 |

| Benzo(a)pyrene | 61 | 23 |

| Bis(2-ethylhexyl) phthalate | 279 | 103 |

| Carbon Tetrachloride | 38 | 18 |

| Chlorobenzene | 28 | 15 |

| Chloroethane | 268 | 104 |

| Chloroform | 46 | 21 |

| 2-Chlorophenol | 98 | 31 |

| Chrysene | 59 | 22 |

| Di-n-butyl phthalate | 57 | 27 |

| 1,2-Dichlorobenzene | 163 | 77 |

| 1,3-Dichlorobenzene | 44 | 31 |

| 1,4-Dichlorobenzene | 28 | 15 |

| 1,1-Dichloroethane | 59 | 22 |

| 1,2-Dichloroethane | 211 | 68 |

| 1,1-Dichloroethylene | 25 | 16 |

| 1,2-trans-Dichloroethylene | 54 | 21 |

| 2,4-Dichlorophenol | 112 | 39 |

| 1,2-Dichloropropane | 230 | 153 |

| 1,3-Dichloropropylene | 44 | 29 |

| Diethyl phthalate | 203 | 81 |

| 2,4-Dimethylphenol | 36 | 18 |

| Dimethyl phthalate | 47 | 19 |

| 4,6-Dinitro-o-cresol | 277 | 78 |

| 2,4-Dinitrophenol | 123 | 71 |

| 2,4-Dinitrotoluene | 285 | 113 |

| 2,6-Dinitrotoluene | 641 | 255 |

| Ethylbenzene | 108 | 32 |

| Fluoranthene | 68 | 25 |

| Fluorene | 59 | 22 |

| Hexachlorobenzene | 28 | 15 |

| Hexachlorobutadiene | 49 | 20 |

| Hexachloroethane | 54 | 21 |

| Methyl Chloride | 190 | 86 |

| Methylene Chloride | 89 | 40 |

| Naphthalene | 59 | 22 |

| Nitrobenzene | 68 | 27 |

| 2-Nitrophenol | 69 | 41 |

| 4-Nitrophenol | 124 | 72 |

| Phenanthrene | 59 | 22 |

| Phenol | 26 | 15 |

| Pyrene | 67 | 25 |

| Tetrachloroethylene | 56 | 22 |

| Toluene | 80 | 26 |

| Total Chromium | 2,770 | 1,110 |

| Total Copper | 3,380 | 1,450 |

| Total Cyanide | 1,200 | 420 |

| Total Lead | 690 | 320 |

| Total Nickel | 3,980 | 1,690 |

| Total Zinc 2 | 2,610 | 1,050 |

| 1,2,4-Trichlorobenzene | 140 | 68 |

| 1,1,1-Trichloroethane | 54 | 21 |

| 1,1,2-Trichloroethane | 54 | 21 |

| Trichloroethylene | 54 | 21 |

| Vinyl Chloride | 268 | 104 |

[52 FR 42568, Nov. 5, 1987, as amended at 58 FR 36892, July 9, 1993]

Subpart J - Direct Discharge Point Sources That Do Not Use End-of-Pipe Biological Treatment

§414.100 Applicability; description of the subcategory of direct discharge point sources that do not use end-of-pipe biological treatment.

The provisions of this subpart are applicable to the process wastewater discharges resulting from the manufacture of the OCPSF products and product groups defined by §414.11 from any point source that does not use end-of-pipe biological treatment and does not install end-of-pipe biological treatment to comply with BPT effluent limitations.

§414.101 Toxic pollutant effluent limitations and standards for direct discharge point sources that do not use end-of-pipe biological treatment.

(a) Any point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentartions in the following table.

(b) In the case of chromium, copper, lead, nickel, zinc, and total cyanide, the discharge quantity (mass) shall be determined by multiplying the concentrations listed in the following table for these pollutants times the flow from metal bearing waste streams for the metals and times the cyanide-bearing waste streams for total cyanide. The metal-bearing waste streams and cyanide-bearing waste streams are defined as those waste streams listed in appendix A of this part, plus any additional OCPSF process wastewater streams identified by the permitting authority on a case-by-case basis as metal or cyanide bearing based upon a determination that such streams contain significant amounts of the pollutants identified above. Any such streams designated as metal or cyanide bearing must be treated independently of other metal or cyanide bearing waste streams unless the permitting authority determines that the combination of such streams, prior to treatment, with the Appendix A waste streams will result in substantial reduction of these pollutants. This determination must be based upon a review of relevant engineering, production, and sampling and analysis information.

| Effluent characteristics | BAT effluent limitations and NSPS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for monthly average | |

| 1 All units are micrograms per liter. 2 Total Zinc for Rayon Fiber Manufacture that uses the viscose process and Acrylic Fibers Manufacture that uses the zinc chloride/solvent process is 6,796 µg/l and 3,325 µg/l for maximum for any one day and maximum for monthly average, respectively. | ||

| Acenaphthene | 47 | 19 |

| Acenaphthylene | 47 | 19 |

| Acrylonitrile | 232 | 94 |

| Anthracene | 47 | 19 |

| Benzene | 134 | 57 |

| Benzo(a)anthracene | 47 | 19 |

| 3,4-Benzofluoranthene | 48 | 20 |

| Benzo(k)fluoranthene | 47 | 19 |

| Benzo(a)pyrene | 48 | 20 |

| Bis(2-ethylhexyl) phthalate | 258 | 95 |

| Carbon Tetrachloride | 380 | 142 |

| Chlorobenzene | 380 | 142 |

| Chloroethane | 295 | 110 |

| Chloroform | 325 | 111 |

| Chrysene | 47 | 19 |

| Di-n-butyl phthalate | 43 | 20 |

| 1,2-Dichlorobenzene | 794 | 196 |

| 1,3-Dichlorobenzene | 380 | 142 |

| 1,4-Dichlorobenzene | 380 | 142 |

| 1,1-Dichloroethane | 59 | 22 |

| 1,2-Dichloroethane | 574 | 180 |

| 1,1-Dichloroethylene | 60 | 22 |

| 1,2-trans-Dichloroethylene | 66 | 25 |

| 1,2-Dichloropropane | 794 | 196 |

| 1,3-Dichloropropylene | 794 | 196 |

| Diethyl phthalate | 113 | 46 |

| 2,4-Dimethylphenol | 47 | 19 |

| Dimethyl phthalate | 47 | 19 |

| 4,6-Dinitro-o-cresol | 277 | 78 |

| 2,4-Dinitrophenol | 4,291 | 1,207 |

| Ethylbenzene | 380 | 142 |

| Fluoranthene | 54 | 22 |

| Fluorene | 47 | 19 |

| Hexachlorobenzene | 794 | 196 |

| Hexachlorobutadiene | 380 | 142 |

| Hexachloroethane | 794 | 196 |

| Methyl Chloride | 295 | 110 |

| Methylene Chloride | 170 | 36 |

| Naphthalene | 47 | 19 |

| Nitrobenzene | 6,402 | 2,237 |

| 2-Nitrophenol | 231 | 65 |

| 4-Nitrophenol | 576 | 162 |

| Phenanthrene | 47 | 19 |

| Phenol | 47 | 19 |

| Pyrene | 48 | 20 |

| Tetrachloroethylene | 164 | 52 |

| Toluene | 74 | 28 |

| Total Chromium | 2,770 | 1,110 |

| Total Copper | 3,380 | 1,450 |

| Total Cyanide | 1,200 | 420 |

| Total Lead | 690 | 320 |

| Total Nickel | 3,980 | 1,690 |

| Total Zinc 2 | 2,610 | 1,050 |

| 1,2,4-Trichlorobenzene | 794 | 196 |

| 1,1,1-Trichloroethane | 59 | 22 |

| 1,1,2-Trichloroethane | 127 | 32 |

| Trichloroethylene | 69 | 26 |

| Vinyl Chloride | 172 | 97 |

[52 FR 42568, Nov. 5, 1987, as amended at 58 FR 36893, July 9, 1993]

Subpart K - Indirect Discharge Point Sources

§414.110 Applicability; description of the subcategory of indirect discharge point sources.

The provisions of this subpart are applicable to the process wastewater discharges resulting from the manufacture of the OCPSF products and product groups defined by §414.11 from any indirect discharge point source.

§414.111 Toxic pollutant standards for indirect discharge point sources.

(a) Any point source subject to this subpart must achieve discharges not exceeding the quantity (mass) determined by multiplying the process wastewater flow subject to this subpart times the concentration listed in the following table.

(b) In the case of lead, zinc, and total cyanide the discharge quantity (mass) shall be determined by multiplying the concentrations listed in the following table for these pollutants times the flow from metal-bearing waste streams for metals and times the flow from the cyanide-bearing waste streams for total cyanide. The metal-bearing waste streams and cyanide-bearing waste streams are defined as those waste streams listed in appendix A of this part, plus any additional OCPSF process wastewater streams identified by the control authority on a case-by-case basis as metal or cyanide bearing based upon a determination that such streams contain significant amounts of the pollutants identified above. Any such streams designated as metal or cyanide bearing must be treated independently of other metal or cyanide bearing waste streams unless the control authority determines that the combination of such streams, prior to treatment, with the appendix A waste streams will result in substantial reduction of these pollutants. This determination must be based upon a review of relevant engineering, production, and sampling and analysis information.

| Effluent characteristics | PSES and PSNS 1 | |

|---|---|---|

| Maximum for any one day | Maximum for any monthly average | |

| 1 All units are micrograms per liter. 2 Total Zinc for Rayon Fiber Manufacture that uses the viscose process and Acrylic Fiber Manufacture that uses the zinc chloride/solvent process is 6,796 µg/l and 3,325 µg/l for maximum for any one day and maximum for monthly average, respectively. | ||

| Acenaphthene | 47 | 19 |

| Anthracene | 47 | 19 |

| Benzene | 134 | 57 |

| Bis(2-ethylhexyl) phthalate | 258 | 95 |

| Carbon Tetrachloride | 380 | 142 |

| Chlorobenzene | 380 | 142 |

| Chloroethane | 295 | 110 |

| Chloroform | 325 | 111 |

| Di-n-butyl phthalate | 43 | 20 |

| 1,2-Dichlorobenzene | 794 | 196 |

| 1,3-Dichlorobenzene | 380 | 142 |

| 1,4-Dichlorobenzene | 380 | 142 |

| 1,1-Dichloroethane | 59 | 22 |

| 1,2-Dichloroethane | 574 | 180 |

| 1,1-Dichloroethylene | 60 | 22 |

| 1,2-trans-Dichloroethylene | 66 | 25 |

| 1,2-Dichloropropane | 794 | 196 |

| 1,3-Dichloropropylene | 794 | 196 |

| Diethyl phthalate | 113 | 46 |

| Dimethyl phthalate | 47 | 19 |

| 4,6-Dinitro-o-cresol | 277 | 78 |

| Ethylbenzene | 380 | 142 |

| Fluoranthene | 54 | 22 |

| Fluorene | 47 | 19 |

| Hexachlorobenzene | 794 | 196 |

| Hexachlorobutadiene | 380 | 142 |

| Hexachloroethane | 794 | 196 |

| Methyl Chloride | 295 | 110 |

| Methylene Chloride | 170 | 36 |

| Naphthalene | 47 | 19 |

| Nitrobenzene | 6,402 | 2,237 |

| 2-Nitrophenol | 231 | 65 |

| 4-Nitrophenol | 576 | 162 |

| Phenanthrene | 47 | 19 |

| Pyrene | 48 | 20 |

| Tetrachloroethylene | 164 | 52 |

| Toluene | 74 | 28 |

| Total Cyanide | 1,200 | 420 |

| Total Lead | 690 | 320 |

| Total Zinc 2 | 2,610 | 1,050 |

| 1,2,4-Trichlorobenzene | 794 | 196 |

| 1,1,1-Trichloroethane | 59 | 22 |

| 1,1,2-Trichloroethane | 127 | 32 |

| Trichloroethylene | 69 | 26 |

| Vinyl Chloride | 172 | 97 |

Appendix A to Part 414 - Non-Complexed Metal-Bearing Waste Streams and Cyanide-Bearing Waste Streams

Chromium

Methylhydroabietate/Esterification of hydroabietic acid (rosin) with methanol

Acrylic acid/Oxidation of propylene via acrolein

N-butyl alcohol/Hydrogenation of n-Butyraldehyde, Oxo process

Cyclohexanone/From phenol via cyclohexanol by hydrogenation-dehydrogenation

Fatty amines/Hydrogenation of fatty nitriles (batch)

Helioptropin/Oxidation of isosafrole, chromium catalyst

Isobutanol/Hydrogenation of isobutyraldehyde, Oxo process

Cyclohexyl Mercaptan/Cyclohexanol Hydrogen sulfide

Ethyl Mercaptan/Ethanol Hydrogen sulfide

Methanol/H.P. Synthesis from natural gas via synthetic gas

Oxo Alcohols, C7-C11/Carbonation & hydrogenation of C6-C10 Olefins

Polyoxypropylene diamine/Polypropylene glycol Ammonia

n-Propyl alcohol/Hydrogenation of propionaldehyde, Oxo process

SAN resin/Suspension polymerization

Styrene/Dehydrogenation of ethylbenzene

Styrene/Dehydration of methyl benzyl alcohol (coproduct of propylene oxide)

1-Tetralol, 1-Tetralone mix/Oxidation of tetralin (1,2,3,4-Tetrahydronaphthalene)

3,3,3-Trifluoropropene/Catalyzed hydrogen fluoride exchange with chlorinated propane

Vinyl toluene/Dehydrogenation (thermal) of ethyltoluene

Copper

Methylhydroabietate/Esterification of hydroabietic acid (rosin) with methanol

Acetaldehyde/Oxidation of ethylene with cupric chloride catalyst

Acetic acid/Catalytic oxidation of butane

Acetone/Dehydrogenation of isopropanol

Acrylamide/Catalytic hydration of acrylonitrile

Acrylic acid/Oxidation of propylene via acrolein

Acrylonitrile/Propylene ammoxidation

Adipic acid/Oxidation of cyclohexanol-cyclohexanone mixture

Adipic acid/Oxidation of cyclohexane via cyclohexanol-cyclohexanone mixture

Allynitrile/Allychloride sodium cyanide

Aniline/Hydrogenation of nitrobenzene

Benzofurans, 2,3-Dihydro-2,2-dimethyl-7-benzofuranol/ from o-Nitrophenol Methallyl chloride

n-Butyl alcohol/Hydrogenation of n-Butyraldehyde, Oxo process

1,4-Butanediol/Hydrogenation of 1,4-butynediol

Butryolactone/Dehydrogenation of 1,4-butanediol

Caprolactam/From cyclohexane via cyclohexanone and its oxime

Lilian (hydroxydihydrocitronellal)/Hydration and oxidation of citronellol

1,2-Dichloroethane/Oxyhydrochlorination of ethylene

Dialkyldithiocarbamates, metal salts/Dialkylamines carbon disulfide

2-Ethylhexanol/from n-Butyraldehyde by Aldo condensation and hydrogenation

Fatty amines/Hydrogenation of fatty nitriles (batch)

Geraniol/B-Myrcene Hydrogen chloride, esterification of geranyl chloride, hydrolysis of geranyl acetate

Furfuryl alcohol/Hydrogenation of furfural

Geranial (Citral)/Oxidation of geraniol (copper catalyst)

Glyoxal/Oxidation of ethylene glycol

Isobutanol/Hydrogenation of isobutyraldehyde, Oxo process

Isopropanol/Catalytic hydrogenation of acetone

2-Mercaptobenzothiazoles, copper salt/2-Mercaptobenzothiazole copper salt

Methanol/High pressure synthesis from natural gas via synthetic gas

Methanol/Low pressure synthesis from natural gas via synthetic gas

Methyl ethyl ketone/Dehydrogenation of sec-Butanol

Oxo alcohols, C7-C11/Carbonation & hydrogenation of C6-C10 olefins

Phenol/Liquid phase oxidation of benzoic acid

Polyoxyalkylene amines/Polyoxyalkylene glycol ammonia

Polyphenylene oxide/Solution polymerization of 2,6-xylenol by oxidative coupling (cuprous salt catalyst)

Polyoxypropylene diamine/Polypropylene glycol Ammonia

Quinaldine (dye intermediate)/Skraup reaction of aniline crotonaldehyde

Silicones, silicone fluids/Hydrolysis and condensation of chlorosilanes

Silicones, silicone rubbers/Hydrolysis and condensation of chlorosilanes

Silicones, silicone specialties (grease, dispersion agents, defoamers & other products)

Silicones: Silicone resins/Hydrolysis & condensation of methyl, phenyl & vinyl chlorosilanes

Silicones: Silicone fluids/Hydrolysis of chlorosilanes to acyclic & cyclic organosiloxanes

Styrene/Dehydration of a-Methylbenzyl alcohol (coproduct of propylene oxide)

Tetrachloroethylene (perchloroethylene)/Oxyhydrochlorination of tetrachloroethane

Tris(anilino)s-triazine/Cyanuric chloride aniline cogeners

Trichloroethylene/Oxyhydrochlorination of tetrachloroethane

Unsaturated polyester resin/Reaction of maleic anhydride phthalic anhydride propylene glycol polyester with styrene or methyl methacrylate

Lead

Alkyd resin/Condensation polymerization

Alkyd resins/Condensation polymerization of phthalic anhydride glycerin vegetable oil esters

Dialkydithiocarbamates, metal salts/Dialkylamines carbon disulfide

Thiuram (dimethyldithiocarbamate) hexasulfide/Dimethyldithiocarbamate sulfur

Triphenylmethane dyes (methyl violet)/Condensation of Formaldehyde N-Methylaniline N,N-dimethylaniline, oxidation of reaction product

4,4?-Bis-(N,N-dimethylaniline) carbinol, Michler's hydrol/Oxidation of 4,4?-Methylene-bis(N,N-dimethylaniline) with lead oxide

Naphthenic acid salts

Stearic acid, metal salts/Neutralization with a metallic base

Nickel

Acetates, 7,11-Hexadecadien-1-ol (gossyplure)/Coupling reactions, low pressure hydrogenation, esterification

Acetates, 9-dodecen-1-ol (pheromone)/Coupling reactions, low pressure hydrogenation, esterification

Acrylic acid/oxidation of propylene via acrolein

Acrylonitrile/Propylene ammoxidation

n-Alkanes/Hydrogenation of C6-C22 alpha olefins (ethylene oligomers)

Adiponitrile/Direct cyanation of butadiene

Alkyl amines/Amination of alcohols

4-Aminoacetanilide/Hydrogenation of 4-Nitroacetanilide

BTX/Hydrogenation of olefins (cyclohexenes)

Terphenyls, hydrogenated/Nickel catalyst, hydrogenation of terphenyl

Bisphenol-A, hydrogenated (Biscyclohexanol-A)/Hydrogenation of Bisphenol-A

Butadiene (1,3)/Extractive distillation of C-4 pyrolyzates

n-Butanol/Hydrogenation of n-Butyraldehyde, Oxo process

1,3-Butylene glycol/Hydrogenation of acetaldol

1,4-Butanediol/Hydrogenation of 1,4-butynediol

Butylenes (mixed)/Distillation pf C4 pyrolyzates

4-Chloro-2-aminophenol/Hydrogenation of 4-Chloro-2-nitrophenol

Lilial (hydroxydihydrocitronellal)/Hydration and oxidation of citronellol

Cycloparaffins/Catalytic hydrogenation of aromatics in kerosene solvent

Cyclohexanol/Hydrogenation of phenol, distillation

Cyclohexanone/From phenol via cyclohexanol by hydrogenation-dehydrogenation

Dialkyldithiocarbamates, metal salts/Dialkylamines carbon disulfide

Ethylamine/Reductive amination of ethanol

Ethylamines (mono, di, tri)/Reductive ammination (ammonia hydrogen) of ethanol

Isoeugenol, high % trans/Separation of mixed cis & trans isoeugenols

2-Ethylhexanol/from n-Butyraldehyde by Aldol condensation and hydrogenation

Fatty acids, hydrogenated/tallow & coco acids Hydrogen

Fatty amines/Hydrogenation of fatty nitriles (batch)

Fatty amines/Hydrogenation of tallow & coco nitriles

Glyoxal-urea formaldehyde textile resin/condensation to N-bis(hydroxymethyl) ureas & N,N?-(dihydroxyethyl) ureas

11-hexadecenal/Coupling rxns, low pressure hydrogenation

Hexahydrophthalic anhydride/Condensation of butadiene & maleic anhydride (Diels-Alder reaction) hydrogenation

Isobutanol/Hydrogenation of isobutyraldehyde, Oxo process

Diisobutyl amine/Ammonolysis of isobutanol

Isopropyl amines (mono, di)/Reductive ammination (Ammonia Hydrogen) of isopropanol

Linalool/Pyrolysis of 2-Pinanol

Methanol/High pressure synthesis from natural gas via synthetic gas

Methanol/Low pressure sythesis fron natural gas via synthetic gas

Methanol/Butane oxidation

Tris-(hydroxymethyl) methyl amine/Hydrogenation of tris(hydroxymethyl) nitromethane

N-Methyl morpholine/Morpholine Methanol

N-Ethyl morpholine/Morpholine Ethanol

2-Methyl-7,8-epoxy octadecane/Coupling reactions, low pressure hydrogenation, epoxidation

Alpha-Olefins/Ethylene oligomer, & Zeigler Cat.

Petroleum hydrocarbon resins, hydrogenated/Hydrogenation of petroleum hydrocarbon resin products

Pinane/Hydrogenation of A-Pinene

2-Pinanol/Reduction of pinane hydroperoxide

Bis-(p-Octylphenol) sulfide, Nickel salt/p-Octylphenol sulfur chloride (S2C12), neutralize with Nickel base

Piperazine/Reductive amination of ethanol amine (ammonia & hydrogenation, metal catalyst)

N,N-Dimethylpiperazine/Condensation piperazine formaldehyde, hydrogenation

Polyoxylalkylene amines/Polyoxyalkylene glycol Ammonia

Polyoxypropylene diamine/Polypropylene glycol Ammonia

2-Amino-2-methyl-1-propanol/Hydrogenation of 2-Nitro 2-methyl-1-propanol

3-Methoxypropyl amine/Reductive amination of acrylamide with methanol & hydrogen

N-Propylamine/Reductive ammination (ammonia hydrogen) of n-propanol

Sorbitol/Hydrogenation of sugars

Sulfolane/Condensation butadiene sulfur dioxide, Hydrogenation

Thionocarbamates, N-Ethyl-o-isopropyl/Isopropyl xanthate Ethylamine

Toluene diamine (mixture)/Catalytic hydrogenation of dinitrotoluene

Methylated urea-formaldehyde resins (textile)/Methylation of urea-formaldehyde adduct

Methylated urea-formaldehyde glyoxol (textile resin)/Reaction of methylated urea-formaldehyde glyoxal

Zinc

Methylhydroabietate, diels-alder adducts/Derivatives of abietic esters from rosin

Acrylic resins/Emulsion or solution polymerization to coatings

Acrylic resins (latex)/Emulsion polymerization of acrylonitrile with polybutadiene

Acrylic fibers (85% polyacrylonitrile) by solution polymerization/Wet spinning

Alkyd Resins/Condensation polymerization of phthalic anhydride glycerin vegetable oil esters

Benzene/By-product of styrene by ethylbenzene dehydrogenation

Benzene/By-product of vinyl toluene (from ethyltoluene)

n-butyl alcohol/Hydrogenation of n-Butyraldehyde, Oxo process

Coumarin (benz-a-pyrone)/Salicylaldehyde, Oxo process

Cycloparaffins/Catalytic hydrogenation of aromatics in kerosene solvent

Dithiocarbamates, zinc salt/Reaction of zinc oxide Sodium dithiocarbamates

Dialkyldithiocarbamates, metal salts/Diakylamines Carbon disulfide

Dithiocarbamates, metal salts/Dithiocarbamic acid metal oxide

Thiuram (dimethyldithiocarbamate) hexasulfide/Dimethyldithiocarbamate sulfur

Fluorescent brighteners/Coumarin based

Ethyl acetate/Redox reaction (Tschenko) of acetaldehyde

Ethylbenzene/Benzene alkylation in liquid phase

Ethylbenzyl chloride/Chloromethylation (Hydrogen chloride formaldehyde, zinc chloride) of ethylbenzene

2-Ethyl hexanol/Aldol condensation-hydrogenation of n-Butyraldehyde

Glyoxal-urea formaldehyde textile resin/Condensation to N-bis (hydroxymethyl) ureas N,N?-(Dihydroxyethyl) ureas

Isobutanol/Hydrogenation of isobutyraldehyde, Oxo process

Isopropanol/Catalytic hydrogenation of acetone

Methallylidene diacetate/Condensation of 2-Methypropenal acetic anhydride

Methanol/Low pressure sythesis from natural gas via synthetic gas

Methyl chloride/Hydrochlorination of methanol

Methylethyl ketone/Dehydrogenation of sec-Butanol

Naphthenic acid salts

Nylon

Nylon 6 & 66 copolymers/Polycondensation of Nylon salt Caprolatam

Nylon 6 fiber/Extrusion (melt spinning)

Oxo alcohols, C12-C15/Hydroformylation & hydrogenation of C11-C14 olefins

Phenolic urethan resins/Phenol excess formaldehyde Methylene aniline diisocyanate

Polystyrene (crystal) modified/Polystyrene sulfonation, chloromethylation and/or amination

Rayon/Viscose process

SAN resin/Emulsion polymerization

Silicones: Silicone rubbers/Hydrolysis and condensation of chlorosilanes

Silicones: Silicone specialties (grease, dispersion agents, defoamers & other products)

Silicones: Silicone resins/Hydrolysis & condensation of methyl, phenyl & vinyl chlorosilanes

Silicones: Silicone fluids/Hydrolysis of chlorosilanes to acyclic & cyclic organosiloxanes

Stearic acid, metal salts/Neutralization with a metallic base

Styrene/Dehydrogenation of ethylbenzene

Styrene-butadiene resin/Emulsion polymerization

Vinyl acetate/Reduction of acetylene acetic acid

Vinyl toluene/Dehydrogenation (thermal) of ethyltoluene

Xylenes, mixed/By-product vinyl toluene (from ethyltoluene)

Cyanide

Acetone cyanohydrin/Acetone Hydrogen cyanide

Acetonitrile/By-product of acrylonitrile from propylene by ammoxidation

Acrylic resins/Solution polymerization

Acrylic fiber (85% acrylonitrile)/Suspension polymerization, and wet spinning

Acrylic fiber (85% acrylonitrile)/Solution polymerization, and wet spinning

Acrylonitrile/Ammoxidation of propylene

Adiponitrile/Butadiene Hydrogen cyanide (direct cyanation)

Allylnitrile/Allyl chloride Sodium cyanide

Dimethoxybenzaldehyde/Hydroquinone dimethyl ether Hydrogen cyanide, hydrolysis

Benzyl cyanide/Benzyl chloride Sodium cyanide

Coal tar products/Distillation of coal tar condensate

Cyanoacetic acid/Chloracetic acid sodium cyanide

Cyanuric chloride/Catalyzed trimerization of cyanogen chloride

Vat dyes, Indigo paste as Vat Blue 1/Sodamide potassium N-Phenylglycine, fused with caustic/N-phenylglycine Aniline Formaldehyde Sodium bisulfite, sodium cyanide, hydrolysis with potassium hydroxide

Disperse dyes, Azo and Vat

Ethylenediamine tetraacetic acid/Ethylenediamine Formaldehyde Sodium cyanide

Diethylenetriamine pentaacetic acid/Diethylenetriamine Formaldehyde Sodium cyanide

N,N?-bis(o-Acetamidophenol)ethylenediamine, ferric complex/ Salicyladehyde Ethylenediamine Hydrogen cyanide, hydrolysis to amide

Diethylenetriamine pentaacetic acid, pentasodium salt/Diethylenetriamine pentaacetic acide caustic

Ethylenediamine tetraacetic acid, metal salts/Ethylenediamine tetraacetic acid metal bases

Hydroxyethyl ethylenediamine triacetic acid, trisodium salt/ Ethylenediamine Ethylene oxide Formaldehyde Sodium cyanide, hydrolysis

5,5-Dimethyl hyantoin/Acetone ammonia carbon dioxide hydrogen cyanide

Hydrogen cyanide/By-product of acrylonitrile by ammoxidation of propylene

Iminodiacetic acid/Hexamethylene tetraamine Hydrogen cyanide, hydrolysis of iminoacetonitrile salt

Methionine/Acrolein Methyl mercaptan, with hydrogen cyanide and ammonium carbonate

Nitrilotriacetic acid/Hexamethylene tetraamine Hydrogen cyanide, hydrolysis of nitrilotriacetonitrile salt

Picolines, mixed/Condensation of acetaldehyde formaldehyde ammonia

Organic pigments, Azo/Diazotization of aniline cogener, coupling to B-Napthol

Pyrimidines, 2-Isopropyl-4-methoxy-/Isobutyronitrile methanol, ammonia and methylacetoacetate (ring closure)

Pyridine (synthetic)/Condensation of acetaldehyde ammonia formaldehyde

Cyanopyridine/Ammoxidation of picoline

Sarcosine (N-Methyl glycine), sodium salt/Hexamethylene tetraamine Sodium cyanide, hydrolysis

Thiophene acetic acid/Chloromethylation (Hydrogen chloride Formaldehyde) Sodium cyanide, hydrolysis

Tris(anilino)S-triazine/Cyanuric chloride Aniline and its cogeners

Triethylorthoformate/Ethanol Hydrogen cyanide

Trimethylorthoformate/Methanol Hydrogen cyanide