['Air Programs']

['Air Emissions', 'Air Programs']

06/13/2024

...

ENVIRONMENTAL PROTECTION AGENCY

40 CFR Part 63

[EPA-HQ-OAR-2002-0083; FRL-5919.1-02-OAR]

RIN 2060-AV82

National Emission Standards for Hazardous Air Pollutants: Integrated Iron and Steel Manufacturing Facilities Technology Review

AGENCY: Environmental Protection Agency (EPA).

ACTION: Final rule.

SUMMARY: The U.S. Environmental Protection Agency (EPA or the Agency) is finalizing amendments to the National Emission Standards for Hazardous Air Pollutants (NESHAP) for Integrated Iron and Steel Manufacturing Facilities to regulate hazardous air pollutant (HAP) emissions. The amendments include: HAP from unmeasured fugitive and intermittent particulate (UFIP) sources previously not regulated by the NESHAP; previously unregulated HAP for sinter plants:; previously unregulated pollutants for blast furnace (BF) stoves and basic oxygen process furnaces (BOPFs) primary control devices; and previously unregulated pollutants for BF primary control devices. We are also finalizing an update to the technology review for this source category.

DATES: This final rule is effective June 3, 2024. The incorporation by reference (IBR) of material publications listed in the rule is approved by the Director of the Federal Register (FR) beginning June 3, 2024. The incorporation by reference (IBR) of certain other material listed in the rule was approved by the Director of the Federal Register (FR) as of July 13, 2020.

ADDRESSES: The EPA established a docket for this action under Docket ID No. EPA-HQ-OAR-2002-0083. All documents in the docket are listed on the https://www.regulations.gov/ website. Although listed, some information is not publicly available, e.g., Confidential Business Information (CBI) or other information whose disclosure is restricted by statute. Certain other material, such as copyrighted material, is not placed on the internet and is publicly available only in hard copy. With the exception of such materials, publicly available docket materials are available electronically in https://www.regulations.gov/ or in hard copy at the EPA Docket Center, Room 3334, WJC West Building, 1301 Constitution Avenue NW, Washington, DC. The Public Reading Room is open from 8:30 a.m. to 4:30 p.m., Monday through Friday, excluding legal holidays. The telephone number for the Public Reading Room is (202) 566-1744, and the telephone number for the EPA Docket Center is (202) 566-1742.

FOR FURTHER INFORMATION CONTACT: For questions about this final action, contact Katie Boaggio, Sector Policies and Programs Division (D243-02), Office of Air Quality Planning and Standards, U.S. Environmental Protection Agency, 109 T.W. Alexander Drive, P.O. Box 12055, Research Triangle Park, North Carolina 27711; telephone number: (919) 541-2223; email address: boaggio.katie@epa.gov.

SUPPLEMENTARY INFORMATION:

Preamble acronyms and abbreviations. Throughout this document the use of “we,” “us,” or “our” is intended to refer to the EPA. We use multiple acronyms and terms in this preamble. While this list may not be exhaustive, to ease the reading of this preamble and for reference purposes, the EPA defines the following terms and acronyms here:

ACI activated carbon injection

BF blast furnace

BOPF basic oxygen process furnace

BTF Beyond-the-Floor

CAA Clean Air Act

CBI Confidential Business Information

COS Carbonyl Sulfide

CFR Code of Federal Regulations

D/F dioxins and furans

EAV equivalent annualized value

EJ environmental justice

EPA Environmental Protection Agency

HAP hazardous air pollutant(s)

HCl hydrochloric acid

HF hydrogen fluoride

HMTDS hot metal transfer, desulfurization, and skimming

ICR Information Collection Request

II&S Integrated Iron and Steel

km kilometer

MACT maximum achievable control technology

NESHAP national emission standards for hazardous air pollutants

NTTAA National Technology Transfer and Advancement Act

OAQPS Office of Air Quality Planning and Standards

OMB Office of Management and Budget

PAH polycyclic aromatic hydrocarbons

PM particulate matter

PBT persistent, bioaccumulative, and toxic

PRA Paperwork Reduction Act

PV present value

RFA Regulatory Flexibility Act

RTR residual risk and technology review

SSM startup, shutdown, and malfunction

THC total hydrocarbons

TEQ toxic equivalency

tpy tons per year

UFIP unmeasured fugitive and intermittent particulate

UMRA Unfunded Mandates Reform Act

UPL upper prediction limit

VCS voluntary consensus standards

VE visible emissions

VOC volatile organic compound

WP work practice

Organization of this document. The information in this preamble is organized as follows:

I. General Information

A. Executive Summary

B. Does this action apply to me?

C. Where can I get a copy of this document and other related information?

D. Judicial Review and Administrative Reconsideration

II. Background

A. What is the statutory authority for this action?

B. What is the source category and how does the current NESHAP regulate its HAP emissions?

C. What changes did we propose for the Integrated Iron and Steel Manufacturing Facilities source category?

III. What is the rationale for our final decisions and amendments for the Integrated Iron and Steel Manufacturing Facilities source category?

A. Standards To Address Five Unregulated UFIP Sources for Both New and Existing Sources

B. Reconsideration of BF Casthouse and BOPF Shop Standards for Currently Regulated Fugitive Sources Under CAA Section 112(d)(6) Technology Review

C. What are the decisions for fenceline monitoring?

D. Standards To Address Unregulated Point Sources for Both New and Existing Sources

E. Reconsideration of Standards for D/F and PAH for Sinter Plants Under CAA Section 112(d)(6) Technology Review, and Beyond-the-Floor Limit for Mercury

F. Other Major Comments and Issues

G. Severability of Standards

H. What are the effective and compliance dates?

IV. Summary of Cost, Environmental, and Economic Impacts

A. What are the affected sources?

B. What are the air quality impacts?

C. What are the cost impacts?

D. What are the economic impacts?

E. What are the benefits?

F. What analysis of environmental justice did we conduct?

V. Statutory and Executive Order Reviews

A. Executive Order 12866: Regulatory Planning and Review and Executive Order 13563: Improving Regulation and Regulatory Review

B. Paperwork Reduction Act (PRA)

C. Regulatory Flexibility Act (RFA)

D. Unfunded Mandates Reform Act (UMRA)

E. Executive Order 13132: Federalism

F. Executive Order 13175: Consultation and Coordination With Indian Tribal Governments

G. National Technology Transfer and Advancement Act (NTTAA) and 1 CFR Part 51

H. Executive Order 12898: Federal Actions To Address Environmental Justice in Minority Populations and Low-Income Populations and Executive Order 14096: Revitalizing Our Nation's Commitment to Environmental Justice for All

I. Executive Order 13045: Protection of Children From Environmental Health Risks and Safety Risks

J. Executive Order 13211: Actions Concerning Regulations That Significantly Affect Energy Supply, Distribution, or Use

K. Congressional Review Act (CRA)

I. General Information

A. Executive Summary

1. Purpose of the Regulatory Action

The EPA set maximum achievable control technology (MACT) standards for the Integrated Iron and Steel Manufacturing Facilities major source category in 2003 (68 FR 27645) under 40 CFR part 63, subpart FFFFF and completed a residual risk and technology review final rule in July 2020 (85 FR 42074). The purpose of this rule is to (1) fulfill the EPA's statutory obligations pursuant to CAA section 112(d)(6); see Louisiana Environmental Action Network v. EPA, 955 F.3d 1088 (D.C. Cir. 2020) (“ LEAN ”), and (2) improve the emissions standards for this source category based on new information regarding developments in practices, processes, and control technologies.

2. Summary of the Major Provisions of the Regulatory Action

To comply with CAA section 112, we are finalizing: (1) new emissions limits based on MACT for five currently unregulated HAP (COS, CS2 , Hg, HCl, and HF) from the sinter plants located at integrated iron and steel manufacturing facilities; and (2) new MACT standards, in the form of opacity limits and work practice (WP) standards, for five unregulated sources of UFIP emissions: Unplanned Bleeder Valve Openings, Planned Bleeder Valve Openings, Slag Pits, Beaching, and Bell Leaks. In this context, opacity is a measure of the amount of light that is blocked or absorbed by an air pollution plume. The components of air pollution that block or absorb light are primarily particulate matter (PM). An opacity level of 0 percent means that plumes of air pollution do not block or absorb light and are fully transparent (i.e., no visible emissions), while an opacity of 100 percent means that plumes are dense and block all light (i.e., the trained observer or special camera cannot see any background behind the plume). Observers are trained and certified using smoke generators which produce known opacity levels, and periodic recertification is required every six months. More details regarding the EPA approved method for opacity readings by a trained observer are available at the following website: https://www.epa.gov/emc/method-9-visual-opacity. Alternatively, opacity can be observed with special cameras following a specific method (known as the digital camera opacity technique (DCOT), 40 CFR 63.7823), and those images interpreted by trained individuals. For the Integrated Iron and Steel Manufacturing sector (and a number of other metals processing and production sectors), a significant portion of the emitted PM is composed of HAP metals (such as arsenic, lead, manganese, and chromium) that are primarily emitted in particulate form as demonstrated in the emissions tests available in the docket for this action. Therefore, for the Integrated Iron and Steel Manufacturing sector, as well as several other industry sectors, PM and opacity serve as surrogates for particulate HAP metals.

We are also finalizing new emissions limits for three unregulated pollutants for BF stoves and BOPFs: THC (as a surrogate for non-dioxin and non-furan organic HAP), HCl, and D/F; and for two unregulated pollutants for BFs: THC (as a surrogate for non-dioxin and non-furan organic HAP) and HCl. In this action, pursuant to CAA section 112(d)(6), we are also finalizing: (1) work practice standards for the basic oxygen process furnace (BOPF) shops; (2) a requirement that facilities conduct Method 9 readings two times per month at the BOPF Shop and BF casthouse; (3) a fenceline monitoring requirement for chromium to help ensure the work practices and opacity limits are achieving the anticipated reductions; and (4) revised standards for D/F and PAHs from sinter plants to reflect the installation and operation of activated carbon injection (ACI) technology. At this time, we are not finalizing the proposed revised opacity limits for the BOPF or the BF casthouse, as explained later in this preamble.

3. Costs and Benefits

To meet the requirements of E.O. 12866, the EPA projected the emissions reductions, costs, and benefits that may result from the final rule. These results are presented in detail in the regulatory impact analysis (RIA) accompanying this final rule developed in response to E.O. 12866. The final rule is significant under E.O. 12866 Section 3(f)(1), as amended by E.O. 14094, due to the monetized benefits of fine particulate matter (PM 2.5 ) reductions likely to result from the UFIP emissions standards included in the final rule. The RIA, which is available in the docket for this action, focuses on the elements of the final rule that are likely to result in quantifiable cost or emissions changes compared to a baseline without these regulatory requirements. We estimated the cost, emissions, and benefit impacts for the 2026 to 2035 period, discounted to 2024. We show the present value (PV) and equivalent annualized value (EAV) of costs, benefits, and net benefits of this action in 2022 dollars. The EAV represents a flow of constant annual values that would yield a sum equivalent to the PV. The EAV represents the value of a typical cost or benefit for each year of the analysis, consistent with the estimate of the PV, in contrast to year-specific estimates.

The initial analysis year in the RIA is 2026 because we assume that will be the first year of full implementation of the rule. We are finalizing that facilities will have 1 year to demonstrate compliance with the relevant standards following promulgation. This analysis assumes that full compliance with the standards will occur in early 2025. Therefore, the first full year of impacts will occur in 2026. The final analysis year is 2035, which allows us to provide ten years of projected impacts after the rule takes effect.

The cost analysis presented in the RIA reflects a nationwide engineering analysis of compliance cost and emissions reductions. Impacts are calculated by setting parameters on how and when affected facilities are assumed to respond to a particular regulatory regime, calculating estimated cost and emissions impact estimates for each facility, differencing from the baseline scenario, and then summing to the desired level of aggregation.

The EPA expects health benefits due to the emissions reductions projected from the rule. We expect that HAP emission reductions will improve health and welfare associated with reduced exposure for those affected by these emissions. In addition, the EPA expects that PM2.5 emission reductions that will occur concurrent with the reductions in HAP emissions will improve air quality and are likely to improve health and welfare associated with exposure to PM2.5 and HAP. For the RIA, the EPA monetized benefits associated with premature mortality and morbidity from reduced exposure to PM2.5 . Discussion of both the monetized and non-monetized benefits can be found in Chapter 4 of the RIA.

Table 1 presents the emission changes and the PV and EAV of the projected monetized benefits, compliance costs, and net benefits over the 2026 to 2035 period under the rule. All discounting of impacts presented uses social discount rates of 3 and 7 percent.

| 3 Percent discount rate | 7 Percent discount rate | |||

|---|---|---|---|---|

| PV | EAV | PV | EAV | |

| a Totals may not sum due to independent rounding. Numbers rounded to two significant digits unless otherwise noted. | ||||

| b Monetized benefits include health benefits associated with reductions in PM 2.5 emissions. The monetized health benefits are quantified using two alternative concentration-response relationships from the Di et al. (2016) and Turner et al. (2017) studies and presented at real discount rates of 3 and 7 percent. The two benefits estimates are separated by the word “and” to signify that they are two separate estimates. Benefits from HAP reductions remain unmonetized and are thus not reflected in the table. | ||||

| Benefits b | $1,800 and $3,700 | $200 and $420 | $1,200 and $2,600 | $170 and $340. |

| Compliance Costs | $45 | $5.3 | $36 | $5.1. |

| Net Benefits | $1,800 and $3,700 | $190 and $410 | $1,200 and $2,600 | $160 and $330. |

| Emissions Reductions (short tons) | 2026-2035 Total | |||

| HAP | 640 | |||

| PM | 18,000 | |||

| PM 2.5 | 4,700 | |||

| Non-monetized Benefits in this Table | HAP benefits from reducing 640 short tons of HAP from 2026-2035. | |||

| Non-health benefits from reducing 18,000 tons of PM, of which 4,700 tons is PM 2.5 , from 2026-2035. | ||||

| Benefits from reducing HCl, HF, Hg, D/F TEQ, COS, and CS2. | ||||

| Visibility benefits. | ||||

| Reduced vegetation effects. | ||||

B. Does this action apply to me?

Table 2 of this preamble lists the NESHAP and associated regulated industrial source category that is the subject of this final rule. Table 2 is not intended to be exhaustive, but rather provides a guide for readers regarding the entities that this final action is likely to affect. The final standards are directly applicable to the affected sources. Federal, state, local, and Tribal government entities are not affected by this final action. As defined in the Initial List of Categories of Sources Under Section 112(c)(1) of the Clean Air Act Amendments of 1990 (see 57 FR 31576; July 16, 1992) and Documentation for Developing the Initial Source Category List, Final Report (see EPA-450/3-91-030; July 1992), the Integrated Iron and Steel Manufacturing Facilities source category is any facility engaged in producing steel from iron ore. Integrated iron and steel manufacturing includes the following processes: sinter production, iron production, iron preparation (hot metal desulfurization), and steel production. The iron production process includes the production of iron in BFs by the reduction of iron-bearing materials with a hot gas. The steel production process occurs in the BOPFs where hot liquid iron from the BF is loaded (i.e., charged) into the BOPF along with coke, lime, alloys, and steel scrap, and includes blowing oxygen into the furnace through a lance resulting in oxidation reactions to produce steel.

| Source category | NESHAP | NAICS code1 |

|---|---|---|

| 1 North American Industry Classification System. | ||

| Integrated Iron and Steel Manufacturing Facilities | 40 CFR part 63, subpart FFFFF | 331110 |

C. Where can I get a copy of this document and other related information?

In addition to being available in the docket, an electronic copy of this action is available on the internet. Following signature by the EPA Administrator, the EPA will post a copy of this final action at https://www.epa.gov/stationary-sources-air-pollution/integrated-iron-and-steel-manufacturing-national-emission-standards. Following publication in the Federal Register , the EPA will post the Federal Register version of the final rule and key technical documents at this same website.

D. Judicial Review and Administrative Reconsideration

Under Clean Air Act (CAA) section 307(b)(1), judicial review of this final action is available only by filing a petition for review in the United States Court of Appeals for the District of Columbia Circuit (D.C. Circuit) by June 3, 2024. Under CAA section 307(b)(2), the requirements established by this final rule may not be challenged separately in any civil or criminal proceedings brought by the EPA to enforce the requirements.

Section 307(d)(7)(B) of the CAA further provides that only an objection to a rule or procedure which was raised with reasonable specificity during the period for public comment (including any public hearing) may be raised during judicial review. This section also provides a mechanism for the EPA to reconsider the rule if the person raising an objection can demonstrate to the Administrator that it was impracticable to raise such objection within the period for public comment or if the grounds for such objection arose after the period for public comment (but within the time specified for judicial review) and if such objection is of central relevance to the outcome of the rule. Any person seeking to make such a demonstration should submit a Petition for Reconsideration to the Office of the Administrator, U.S. EPA, Room 3000, WJC South Building, 1200 Pennsylvania Ave. NW, Washington, DC 20460, with a copy to both the person(s) listed in the preceding. FOR FURTHER INFORMATION CONTACT section, and the Associate General Counsel for the Air and Radiation Law Office, Office of General Counsel (Mail Code 2344A), U.S. EPA, 1200 Pennsylvania Ave. NW, Washington, DC 20460.

II. Background

A. What is the statutory authority for this action?

This action finalizes amendments to the National Emission Standards for Hazardous Air Pollutants (NESHAP) for the Integrated Iron and Steel Manufacturing Facilities source category. The statutory authority for this action is provided by section 112 of the CAA, as amended (42 U.S.C. 7401, et seq. ). In the first stage of the CAA section 112 standard-setting process, the EPA promulgates technology-based standards under CAA section 112(d) for categories of sources identified as emitting one or more of the HAP listed in CAA section 112(b). Sources of HAP emissions are either major sources or area sources, and CAA section 112 establishes different requirements for major source standards and area source standards. “Major sources” are those that emit or have the potential to emit 10 tons per year (tpy) or more of a single HAP or 25 tpy or more of any combination of HAP. All other sources are “area sources.”

For major sources, CAA section 112(d)(2) provides that the technology-based NESHAP must reflect the maximum degree of emission reductions of HAP achievable after considering cost, energy requirements, and non-air quality health and environmental impacts. These standards are commonly referred to as MACT standards. CAA section 112(d)(3) also establishes a minimum control level for MACT standards, known as the MACT “floor.” In certain instances, as provided in CAA section 112(h), if it is the judgment of the Administrator that it is not feasible to prescribe or enforce an emission standard, the EPA may set work practice standards in lieu of numerical emission standards. The EPA must also consider control options that are more stringent than the floor, commonly referred to as “beyond-the-floor” (BTF) standards.

CAA section 112(d)(6) requires the EPA to review standards promulgated under CAA section 112 and revise them “as necessary (taking into account developments in practices, processes, and control technologies)” no less often than every eight years. While conducting this review, which we call the “technology review,” the EPA is not required to recalculate the MACT floors that were established during earlier rulemakings. Nat. Resources Def. Council, et al. v. EPA, 529 F.3d 1077, 1084 (D.C. Cir. 2008); Ass'n of Battery Recyclers, Inc. v. EPA, 716 F.3d 667 (D.C. Cir. 2013). The EPA may consider cost in deciding whether to revise the standards pursuant to CAA section 112(d)(6). However, costs may not be considered when setting the MACT floor and may only be considered when determining whether beyond-the-floor standards are appropriate. See CAA section 112(d)(3).

CAA section 112(f) requires the EPA to determine whether promulgation of additional standards is needed to provide an ample margin of safety to protect public health or to prevent an adverse environmental effect. This review is known as the “residual risk review,” and it must occur within eight years after promulgation of the standards. When the EPA conducts the “technology review” together with the “residual risk review,” the combined review is known as a “risk and technology review” or “RTR.”

The EPA initially promulgated the Integrated Iron and Steel Manufacturing Facilities NESHAP on May 20, 2003 (68 FR 27645), codified at title 40, part 63, subpart FFFFF (the NESHAP). The rule was amended on July 13, 2006 (71 FR 39579). The amendments added a new compliance option, revised emission limitations, reduced the frequency of repeat performance tests for certain emission units, added corrective action requirements, and clarified monitoring, recordkeeping, and reporting requirements.

In 2015, a coalition of environmental advocacy groups filed a lawsuit to compel the EPA to fulfill its statutory duty to conduct the CAA sections 112(d) and 112(f)(2) reviews of 21 NESHAPs, including Integrated Iron and Steel Manufacturing Facilities. As a result of that litigation, the EPA was required by court order to complete the RTR for the Integrated Iron and Steel Manufacturing Facilities source category by May 5, 2020. California Communities Against Toxics v. Wheeler, No. 1:15-00512, Order (D.D.C. March 13, 2017, as modified Feb. 20, 2020). The resulting RTR conducted for the Integrated Iron and Steel Manufacturing Facilities NESHAP was signed on May 4, 2020. 85 FR 42074 (July 13, 2020).

In an April 2020 decision by the U.S. Court of Appeals for the District of Columbia Circuit, on a petition for review of the EPA's NESHAP rulemaking for a different source category (pulp mill combustion sources), the court held that the EPA has an obligation to address all unregulated HAP emissions from a source category when the Agency conducts the eight-year technology review required by CAA section 112(d)(6). Louisiana Environmental Action Network v. EPA, 955 F.3d 1088, 1098-99 (“LEAN” ). The parties in California Communities Against Toxics thereafter filed a joint motion to extend those deadlines to allow the EPA to revise the rules in accordance with the LEAN opinion. The court granted the motion, setting a new deadline for this rule of October 26, 2023. Order, California Communities Against Toxics, No. 15-512 (D.D.C. April 14, 2021). Based on further negotiation between the parties, the deadline for this final rule was changed to March 11, 2024. Minute Order, California Communities Against Toxics, No. 15-512 (D.D.C. Sept. 20, 2023).

In September 2021, industry and environmental advocacy groups filed petitions for review of the 2020 Integrated Iron and Steel Manufacturing Facilities final rule, and these petitions have been consolidated. American Iron and Steel Inst., et al. v. EPA, No. 20-1354 (D.C. Cir.); Clean Air Council, et al. v. EPA, No. 20-1355 (D.C. Cir.). The consolidated case is being held in abeyance pending the promulgation of this final rule. See EPA's Unopposed Mot. to Hold Cases in Abeyance, No. 20-1354 (consol.) (D.C. Cir.), Dkt. No. 2028131 (reporting to the D.C. Circuit the March 11, 2024 final rule deadline); Order, American Iron and Steel Inst., No. 20-1354 (consol.) (D.C. Cir. Dec. 7, 2022).

In light of this litigation history, this final rule addresses multiple issues, including: (1) new standards to address previously unregulated emissions of HAP from the Integrated Iron and Steel Manufacturing Facilities source category pursuant to the LEAN decision and CAA sections 112(d)(2) and (3) and 112(h) and, (2) revised standards for a few currently regulated HAP, as well as fenceline monitoring requirements, pursuant to the CAA section 112(d)(6) technology review.

B. What is the source category and how does the current NESHAP regulate its HAP emissions?

As described above, the Integrated Iron and Steel Manufacturing Facilities source category includes any facility engaged in producing steel from refined iron ore (also known as taconite pellets). These facilities first produce iron from iron ore taconite pellets, sinter, coke, and other raw materials using blast furnaces (BFs), then produce steel from the hot liquid iron produced from the blast furnaces, along with coke, lime, alloys, steel scrap, and other raw materials using basic oxygen process furnaces (BOPFs). Integrated iron and steel manufacturing includes the following processes: sinter production, iron production, iron preparation (hot metal desulfurization), and steel production. The iron production process includes the production of iron in BFs by the reduction of iron-bearing materials with a very hot gas. The steel production process includes BOPFs and ladle metallurgy operations. Currently there are eight operating facilities in this source category.

The main sources of HAP emissions from integrated iron and steel manufacturing are the BF; BF stove; BOPF; hot metal transfer, desulfurization, and skimming (HMTDS) operations; ladle metallurgy operations; sinter plant windbox; sinter plant discharge end; and sinter cooler. All eight facilities have BFs, BF stoves, BOPFs, HMTDS operations, and ladle metallurgy operations. However, only three facilities have sinter plants and only two facilities with currently operating sinter plants.

The following are descriptions of the BF, BOPF, and sinter plants:

- The BF is a key integrated iron and steel process unit where molten iron is produced from raw materials such as iron ore, lime, sinter, coal and coke.

- The BOPF is a key integrated iron and steel process unit where steel is made from molten iron, scrap steel, lime, dolomite, coal, coke, and alloys

- Sinter is derived from material formed in the bottom of the blast furnace, composed of oily scale, blast furnace sludge, and coke breeze, along with tarry material and oil absorbed from the sump in which the sinter is recovered. The sinter plant processes the waste that would otherwise be landfilled so that iron and other valuable materials can be re-used in the blast furnace. Only three sources covered by the Integrated Iron and Steel Manufacturing Facility category have sinter plants, down from nine facilities with sinter plants in 2003.

In addition to point sources, the EPA identified seven UFIP emission sources for this source category, including BF bleeder valve unplanned openings, BF bleeder valve planned openings, BF bell leaks, BF casthouse fugitives, BF iron beaching, BF and BOPF slag handling and storage operations, and BOPF shop fugitives. These UFIP emission sources were identified by observation of visible plumes by EPA regional staff during onsite source inspections and were subsequently investigated to determine the causes and any possible methods for reductions. These inspections are documented in numerous reports and photographs between 2008 and the present. 1 The NESHAP regulates two of these sources—BF casthouse fugitives and BOPF shop fugitives—with opacity limits. 1See, e.g., communications between B. Dickens and P. Miller, U.S. EPA Region V, Chicago, IL, with D.L. Jones, U.S. EPA, Office of Air Quality Planning and Standards, Office of Air and Radiation, 2015-2018. See also Ample Margin of Safety for Nonpoint Sources in the II&S Industry. Both documents are available in the docket to this rule.

The following are descriptions of the main process units and the seven UFIP sources:

- The BF is a key integrated iron and steel process unit where molten iron is produced from raw materials such as iron ore, lime, sinter, coal and coke.

- The BOPF is a key integrated iron and steel process unit where steel is made from molten iron, scrap steel, lime, dolomite, coal, coke, and alloys.

- Sinter is derived from material formed in the bottom of the blast furnace, composed of oily scale, blast furnace sludge, and coke breeze, along with tarry material and oil absorbed from the sump in which the sinter is recovered. The sinter plant processes the waste that would otherwise be landfilled so that iron and other valuable materials can be re-used in the blast furnace. Only three sources covered by the Integrated Iron and Steel Manufacturing Facility category have sinter plants, down from nine facilities with sinter plants in 2003.

- The BOPF shop is the structure that houses the entire BOPF and auxiliary activities, such as hot iron transfer, skimming, and desulfurization of the iron and ladle metallurgy operations, which generate fugitive emissions.

- The BF casthouse is the structure that houses the lower portion of the BF and encloses the tapping operation and the iron and slag transport operations, which generate fugitive emissions.

- The bleeder valve is a device at the top of the BF that, when open, relieves BF internal pressure to the ambient air. The valve can operate as both a self-actuating safety device to relieve excess pressure and as an operator-initiated instrument for process control. A bleeder valve opening means any opening of the BF bleeder valve, which allows gas and/or PM to flow past the sealing seat. Multiple openings and closings of a bleeder valve that occur within a 30-minute period could be considered a single bleeder valve opening. There are two types of openings, planned and unplanned.

- A planned bleeder valve opening means an opening that is initiated by an operator as part of a furnace startup, shutdown, or temporary idling for maintenance action. Operators can prepare the furnace for planned openings to minimize or eliminate emissions from the bleeder valves.

- An unplanned bleeder valve opening means an opening that is not planned and is caused by excess pressure within the furnace. The pressure buildup can occur when raw materials do not descend smoothly after being charged at the top of the BF and accumulate in large masses within the furnace. When the large masses finally dislodge (slip) due to their weight, a pressure surge results.

- Slag is a by-product containing impurities that is released from the BF or BOPF along with molten iron when the BF or BOPF is tapped from the bottom of the furnace. The slag is less dense than iron and, therefore, floats on top of the iron. Slag is removed by skimmers and then transported to open pits to cool to enable later removal. Usually there is one slag pit for every BF or BOPF.

- Iron beaching occurs when iron from a BF cannot be charged to the BOPF because of problems in steelmaking units; the hot molten iron from the BF is placed onto the ground, in some cases within a three-sided structure.

- The BF bells are part of the charging system on top of the furnace that allows for materials to be loaded into the furnace or next bell (as in the case of small bells) without letting BF gas escape. It is a two-bell system, where a smaller bell is above a larger bell. These bells must be tightly sealed to the blast furnace when not in use for charging, so that BF gas and uncontrolled emissions do not escape to the atmosphere. Over time, the surfaces that seal the bells wear down and need to be repaired or replaced. If these seals are not repaired or replaced in a timely manner, emissions of HAP and PM can increase significantly.

In the 2020 final rule, the Agency found that risks due to emissions of air toxics from this source category were acceptable and concluded that the NESHAP provided an ample margin of safety to protect public health. Although the 2020 NESHAP found the risks acceptable and no new requirements should be imposed, new data was collected via a CAA section 114 request to industry after re-opening the rule, due to the LEAN court decision. These new data necessitated technology review updates, in addition to establishing new MACT standards for unregulated HAPs pursuant to the LEAN court decision. Under the technology review in the 2020 RTR, the EPA found no developments in practices, processes, or control technologies that necessitated revision of the standards at that time. However, in response to a 2004 administrative petition for reconsideration of the 2003 NESHAP, the 2020 final rule promulgated a new MACT emissions limit for mercury (0.00026 lbs mercury/ton scrap metal) with two compliance options: (1) conduct annual compliance tests (to demonstrate compliance with the MACT limit); or (2) confirm that the facility obtains their auto scrap from suppliers that participate in the National Vehicle Mercury Switch Recovery Program (NVMRP) or another approved mercury switch removal program or that the facility only uses scrap that does not contain mercury switches. We also removed exemptions for periods of startup, shutdown, and malfunction (SSM) consistent with Sierra Club v. EPA, 551 F.3d 1019 (D.C. Cir. 2008); clarified that the emissions standards apply at all times; added electronic reporting of performance test results and compliance reports; and made minor corrections and clarifications for a few other rule provisions. All documents used to develop the previous 2003, 2006, and 2020 final rules can be found in either the legacy docket, A-2000-44, or the electronic docket, EPA-HQ-OAR-2002-0083.

The NESHAP includes emissions limits for PM and opacity standards—both of which are surrogates for non-mercury PM HAP metals—for furnaces and sinter plants. To support the continued use of PM as a surrogate for certain non-mercury HAP metals, we considered the holding in National Lime Ass'n v. EPA, 233 F.3d 625 (D.C. Cir. 2000). In considering whether the EPA may use PM, a criteria pollutant, as a surrogate for metal HAP, the D.C. Circuit stated that the EPA “may use a surrogate to regulate hazardous pollutants if it is `reasonable' to do so,” id. at 637, establishing criteria for determining whether the use of PM as a surrogate for non-mercury metal HAP was reasonable. The court found that PM is a reasonable surrogate for HAP if: (1) “HAP metals are invariably present” in the source's PM,” id. ; (2) the “source's PM control technology indiscriminately captures HAP metals along with other particulates,” id. at 639; and (3) “PM control is the only means by which facilities `achieve' reductions in HAP metal emissions,” id. If these criteria are satisfied and the PM emission standards reflect what the best sources achieve in compliance with CAA section 112(d)(3), then “EPA is under no obligation to achieve a particular numerical reduction in HAP metal emissions.” Id. The EPA has established and promulgated PM limits as a surrogate for particulate HAP metals successfully in several NESHAP regulations, including Ferroalloys Production (80 FR 37366, June 30, 2015), Taconite Iron Ore Processing (68 FR 61868), and Primary Copper Smelting (67 FR 40478, June 12, 2002).

The NESHAP also includes an operating limit for the oil content of the sinter plant feedstock or, as an alternative, an emissions limit for volatile organic compounds (VOC) for the sinter plant windbox exhaust stream. The oil limit, and the alternative VOC limit, serve as surrogates for all organic HAP. Moreover, the NESHAP includes an emissions limit for mercury emissions from the BOPF Group, which is the collection of BOPF shop steelmaking operating units and their control devices including the BOPF primary emission control system, BOPF secondary control system, ladle metallurgy units, and hot metal transfer, desulfurization and slag skimming units.

C. What changes did we propose for the Integrated Iron and Steel Manufacturing Facilities source category?

On July 31, 2023, the EPA published a proposal in the Federal Register to set standards to regulate HAP emissions from five UFIP sources that were not previously regulated by the NESHAP: Bell Leaks, Unplanned Bleeder Valve Openings, Planned Bleeder Valve Openings, Slag Pits, and Beaching. For sinter plants, we proposed standards for five previously unregulated HAP: COS, CS2 , Hg, HCl, and HF. For BF stoves and BOPFs, we proposed standards for three previously unregulated pollutants: THC (as a surrogate for non-dioxin and non-furan organic HAP), HCl, and D/F. And for BFs, we proposed standards for two previously unregulated pollutants: THC (as a surrogate for non-dioxin and non-furan organic HAP) and HCl.

As an update to the technology review, we proposed to revise the previous BOPF shop fugitive 20 percent opacity limit to a 5 percent opacity limit and require specific work practices; revise the current BF casthouse fugitive 20 percent opacity limit to a 5 percent opacity limit; and revise the current standards for D/F and PAH for sinter plants to reflect current control performance of sinter plants for these HAP. We also proposed a fenceline monitoring requirement for Cr, including a requirement that if a monitor exceeds the proposed Cr action level, the facility would need to conduct a root cause analysis and take corrective action to lower emissions.

III. What is the rationale for our final decisions and amendments for the Integrated Iron and Steel Manufacturing Facilities source category?

For each issue, this section provides a description of what we proposed and what we are finalizing, a summary of key comments and responses, and the EPA's rationale for the final decisions and amendments. For all comments not discussed in this preamble, comment summaries and the EPA's responses can be found in the document, Summary of Public Comments and Responses for Proposed Amendments to the National Emission Standards for Hazardous Air Pollutants for Integrated Iron and Steel Manufacturing Facilities, which is available in the docket for this action. This document is also referred to as the Response to Comments (RTC) in subsequent sections of this preamble.

A. Standards To Address Five Unregulated UFIP Sources for Both New and Existing Sources

1. What did we propose for the five previously unregulated UFIP sources?

a. BF Unplanned Bleeder Valve Openings

Based on the data we received through the CAA section 114 requests, the average number of unplanned openings of the best performing five furnaces in the source category is 5 unplanned openings per year. Therefore, we proposed an operational limit of five unplanned openings per year per furnace for existing sources, which was an estimate of the MACT floor level of performance for existing sources. For new sources, we proposed an operational limit of zero unplanned openings per year because the best performing single source in our database reported zero unplanned openings for the most recent representative year.

Additionally, we proposed work practice standards that would require facilities to do the following: (1) install and operate devices (e.g., stockline monitors) to continuously measure/monitor material levels in the furnace, at a minimum of three locations, using alarms to inform operators of static conditions that indicate a slip may occur and alert them that there is a need to take action to prevent the slips and unplanned openings from occurring; (2) install and operate instruments such as a thermocouple and transducer on the furnace to monitor temperature and pressure to help determine when a slip may occur; (3) install a screen to remove fine particulates from raw materials to ensure only properly-sized raw materials are charged into the BF; and (4) develop, and submit to the EPA for approval, a plan that explains how the facility will implement these requirements. Additionally, we proposed that facilities would need to report the unplanned openings (including the date, time, duration, and any corrective actions taken) in their semiannual compliance reports.

b. BF Planned Bleeder Valve Openings

Based on our evaluation of available information and pursuant to CAA section 112(d)(2) and (3), for existing sources we proposed a MACT floor limit of 8 percent opacity for any 6-minute averaging period for the BF planned bleeder valve openings. We did not propose the BTF option of 5 percent opacity for existing sources because we determined that 5 percent opacity may not be feasible for some sources on a consistent basis. For new sources, we proposed an opacity of 0 percent because based on the available data, the best performing single source had opacity of 0 percent during the planned opening. We expect that new sources will be able to configure their furnace design and operations similarly to the best performing single source which, in combination with utilizing the suggested work practices described in the document Unmeasurable Fugitive and Intermittent Particulate Emissions and Cost Impacts for Integrated Iron and Steel Facilities under 40 CFR part 63, subpart FFFFF, should allow them to achieve an opacity of 0 percent. We did not propose any work practices under CAA section 112(h) for the BF planned bleeder valve openings; facilities will have the flexibility to choose an appropriate approach to meet the opacity limit.

c. BF and BOPF Slag Processing, Handling, and Storage

Based on our analyses and pursuant to CAA section 112(d)(2) and (3), for existing sources we proposed a BTF opacity limit of 5 percent based on 6-minute averages for visible emissions from slag pits and during slag handling, storage, and processing. Regarding new sources, we proposed a MACT floor opacity limit of 2.5 percent based on 6-minute averages for visible emissions from slag pits and during slag handling, storage, and processing.

d. BF Bell Leaks

Based on our evaluation and pursuant to CAA section 112(d)(2) and (3), we proposed 10 percent opacity as an action level, as described below in this paragraph, for large bell leaks (not a MACT emissions limit). Along with this action level, we also proposed that the BF top will need to be observed monthly for visible emissions (VE) with EPA Method 22, 40 CFR part 60, appendix A-7, which determines the presence or absence of a visible plume, to identify leaks, and if VE are detected out of the interbell relief valve (indicating leaks from the large bell), we proposed that the facility would then need to perform EPA Method 9, 40 CFR part 60, appendix A-4, tests which determines the opacity (i.e., degree to which a plume obscures the background), monthly and if opacity is greater than 10 percent (based on a 3-minute average), the large bell seals will need to be repaired or replaced within 4 months. For the small bell, we proposed that facilities will need to replace or repair seals prior to a metal throughput limit, specified by the facility, that has been proven and documented to produce no opacity from the small bells.

e. Beaching of Iron From BFs

Pursuant to CAA section 112(d)(2) and (3) and CAA section 112(h), we proposed a MACT standard that would require facilities to: (1) have full or partial enclosures for the beaching process or use CO2 to suppress fumes; and (2) minimize the height, slope, and speed of beaching.

2. What comments did we receive on the proposed standards and, what are our responses?

a. BF Unplanned Bleeder Valve Openings

Comment: Commenters stated that in developing the proposed limit on the number of unplanned pressure release device (PRD) openings that could occur within a year, the EPA treated all BFs alike by placing them in a single category. Commenters stated that because larger BFs are able to accommodate higher internal pressures before the need for an unplanned opening, the EPA should create two separate subcategories of blast furnaces. Commenters stated that in reviewing data for unplanned PRD openings, they believed that subcategorization is appropriate and necessary if an action level or limit of any type is to be established for the number of events. In particular, commenters noted that large BFs have significantly fewer unplanned openings, where “Large BF” is defined as a BF with a working volume greater than 2,500 cubic meters (m3 ). Commenters also stated that the EPA did not account for variability across sources and asked EPA to apply an upper prediction limit (UPL) if it were to finalize a limit on unplanned openings. Commenters stated that a 99 percent UPL analysis of the data supports limits of 52 unplanned openings for large BFs and 112 unplanned openings for small BFs.

Response: We agree with the commenter that larger BFs are able to accommodate higher internal pressure and that subcategorization based on BF size is appropriate. In this final rule, we define “large BF” as a BF with a working volume greater than 2,500 m3 and are establishing separate limits on unplanned openings for large and small BF.

EPA also agrees with commenters that it is important to account for variability in the incidence of unplanned openings. Accordingly, in the final rule the EPA has decided to base the limit on the highest number of unplanned openings reported within the top five sources to ensure that we adequately account for variability, rather than the proposed approach of basing the limit on the average number of unplanned openings within the top five sources.

EPA disagrees with commenters' suggestion that it should apply a 99 percent UPL to determine the limit on unplanned openings. The EPA commonly uses the 99 percent UPL to calculate numerical emissions limits based on stack test data (e.g., grams of HAP per cubic meter of stack exhaust gases). The UPL method is not appropriate to evaluate a count of unplanned openings because these are discrete events and are therefore not analogous to emissions data or test runs. In the context of this final rule, application of the UPL would therefore not appropriately reflect variability and would lead to an exceedingly high limit on unplanned openings that does not reflect the performance achieved at top- performing sources. As noted above, the EPA has instead accounted for variability in this final rule by basing the limit on the highest number of unplanned openings observed among the five top-performing sources.

b. BF Planned Bleeder Valve Openings

Comment: Commenters agreed that these opacity limits will result in HAP reductions. Accordingly, commenters supported these revisions and additions and encouraged the EPA to not weaken any of the proposed limits.

Response: EPA appreciates the support and agrees that these opacity limits for planned bleeder valve openings will result in HAP reductions.

Comment: EPA should not adopt the proposed 8% opacity limit and weekly Method 9 testing for planned openings in addition to the new work practice standards. PRD openings by operators are routinely necessary and appropriate for proper BF operation. Emissions from planned openings are exceedingly low, ranging from 1.6 tpy to 0.3 tpy, with reductions projected between 0.4 and 0.08 tpy across the entire industry. The work practice standards are expensive, with estimated cost-effectiveness based upon the proposed rule having rates ranging from $134,000/ton to $672,000/ton. No regulation of these small contributors should occur. If EPA nonetheless moves forward, there should be an action level at 15% (based on a more robust UPL analysis).

Response: Based on our evaluation of public comments and available information, pursuant to CAA section 112(d)(2) and (3) and the LEAN court decision, for existing sources we are promulgating a MACT Floor limit of 8 percent opacity for any 6-minute averaging period for the BF planned bleeder valve openings. The MACT floor is the least stringent standard allowed by section 112 of the Clean Air Act. For new sources, we are promulgating an opacity of 0 percent because based on the available data, the best performing single source had opacity of 0 percent during the planned opening, which we consider the MACT Floor level for new sources pursuant to CAA section 112. As we explained in the proposed rule, we determined based on evaluation of available information that emissions can be minimized from bleeder valve planned openings cost effectively by implementing various actions before the valves are opened such as: (1) tapping as much liquid (iron and slag) out of the furnace as possible; (2) removing fuel and/or stopping fuel injection into the furnace; and (3) lowering bottom pressure. However, as explained in the proposed rule preamble, we did not propose any specific work practices for the BF planned bleeder valve openings and we are maintaining the decision to not require any specific work practices for the final rule. Facilities will have the flexibility to choose an appropriate approach to meet the opacity limit.

We estimate that this standard will result in about 0.41 tpy reduction in HAP metal emissions. The estimated cost is $54,600/yr for the entire category and $6,800/yr per facility. The estimated cost effectiveness is $134,000 per ton of HAP metals.

c. BF and BOPF Slag Processing, Handling, and Storage

Comment: Commenters stated that the proposed 5 percent opacity limit for slag handling operations should not be adopted. They contend that it is virtually impossible to enclose the extremely hot slag material or to universally apply water at all times to help suppress emissions because of the volatile nature of the material and the potential for a life-threatening hazardous explosion when the water violently expands in the form of steam. Commenters stated that the EPA had ignored these important safety concerns in proposing the 5 percent opacity limit, and that the control measures the EPA had identified to meet this limit could not be reasonably utilized. Commenters also argued that even if EPA's suggested control measures were applied, a UPL analysis would result in an opacity limit of 20 percent, far exceeding the proposed 5 percent level. Commenters noted that the EPA had improperly failed to account for variability in the performance of sources by declining to apply a UPL or other statistical analysis.

Response: After considering these comments, we agree that a limit of 5 percent opacity could result in higher cost impacts than we estimated at proposal for some facilities. As described in the proposed rule Federal Register notice published on July 31, 2023 (88 FR 49402), the proposed 5 percent opacity limit was a beyond-the-floor limit based on the EPA's understanding at that time that emissions could be cost effectively minimized from slag pits with the application of water spray or fogging and/or other work practices such as installing wind screens, dust suppression misters, and maintaining a high moisture content of the slag during handling, storage, and processing. However, at proposal we did not account for variability and certain other factors such as weather conditions and possible safety issues. Although we still conclude that these measures can help minimize emissions, these measures might not be sufficient to consistently maintain opacity below 5 percent.

In the proposed rule FR notice, we also described a potential MACT floor opacity limit of 9 percent for existing sources which was based on the straight average of the top five performing facilities. Based on the comments submitted, the EPA is finalizing an opacity limit of 10 percent based on a MACT floor analysis for existing sources. This final limit is based on the average opacity of 9 percent reported by the five top performing facilities, but rounding up slightly to 10 percent to account for variability. The EPA has historically used the UPL approach to develop MACT limits for stack emissions of individual pollutants, but has not historically determined opacity limits using a UPL approach. The UPL calculation introduces a predictive element to the statistics in order to account for variability. However, unlike typical emissions testing, EPA Method 9 tests frequently result in values of zero, which cannot be used in the UPL calculation so this approach for accounting for variability was not used. The EPA determined that rounding the opacity from 9 percent to 10 percent sufficiently accounts for variability in this process. Therefore, in this final rule we are promulgating a 10 percent opacity limit (based on six-minute averages) for slag processing, handling, and storage. Because this 10 percent opacity limit has been achieved in practice by top performing facilities, we expect that all facilities will be able to achieve this 10 percent opacity limit by application of some or all of the work practices described above and in the proposed rule Federal Register notice (88 FR 49402). Other comments and responses on this issue are provided in the RTC.

d. BF Bell Leaks

Comment: Commenters expressed concerns that the proposed triggers for action for large bells are too low and that the repair and replacement time should consider lead time and operational concerns. Commenters suggested that with this in mind, the EPA could establish a 20 percent opacity action level (6-minute average) with quarterly EPA Method 9 observation requirements. Under this approach, if a facility observes opacity in excess of 20 percent, the facility should be required to investigate, make operational changes, and conduct a repair, followed by repeat testing using EPA Method 9 to confirm the efficacy of the repair. If repairs are not successful, only then would replacement obligations be triggered. Other commenters stated that if the EPA moves forward with work practice standards, the EPA should consider an alternative under which a facility would need to initiate operational or other corrective actions within five business days if an EPA Method 9 test identifies opacity of 20 percent or more. If the facility does not reduce opacity to less than 20 percent with those actions, the facility would have another five business days to initiate further operational or other corrective actions to reduce opacity to less than 20 percent. Only if the second attempt does not result in opacity of 20 percent or less would the test result be deemed a deviation requiring reporting and corrective actions, such as moving to the repair step or, if necessary, replacement of the large bell.

Response: We agree with the commenter who suggested the two-step approach for large bells is appropriate as well as the suggestion of 20% opacity instead of 10% opacity as a trigger. As discussed by the commenter, the replacement of bells is costly and there are numerous more cost-effective repair options available that can be achieved in a shorter time period to avoid full repair and replacement. This would help keep the bell repairs on a more organized schedule. Therefore, we decided to finalize a 20 percent opacity action level (instead of the proposed 10 percent opacity action level) and provide two five-business day periods to investigate the opacity trigger, as suggested by the commenter. Specifically, we changed the requirement to the following: if EPA Method 9 identifies opacity greater than 20 percent, the facility shall initiate corrective actions within five business days. If the first attempt to correct fails and EPA Method 9 again identifies that opacity is not reduced to 20 percent or lower, the facility would have another five business days to initiate further corrective actions to reduce opacity to 20 percent or lower. Only if the second attempt does not result in an opacity of 20 percent or less would it become a deviation, requiring reporting and corrective actions that we included in the proposed rule, such as moving to the repair step or, if unsuccessful, replacement of the large bell.

e. Beaching of Iron From BF's

Comment: Commenters supported the proposal to require facilities to: (1) have full or partial enclosures for the beaching process or use CO2 to suppress fumes; and (2) minimize the height, slope, and speed of beaching. Commenters supported the addition of monitoring of vents from the partial enclosures to allow for additional information and accountability for these sources.

Response: EPA appreciates the support for the beaching requirements in the proposed rule.

Comment: Industry commenters stated that the proposed work practice standards to address already low emissions from beaching events, which the industry consistently works to minimize, would not provide meaningful reductions and would be extremely costly. Industry commenters estimated about 4 pounds per year of reduction from these proposed measures, lower than the estimates EPA provided in the final rule. Commenters also pointed out that EPA's estimated cost per ton of removal would be $15.8 million/ton and argued that this amount is unreasonable notwithstanding EPA's explanation that it must adhere to the floor provisions of the statute. Commenters stated that if EPA were to use the more accurate emissions and cost information provided by industry, the cost-effectiveness rate estimate based upon the proposed rule would be multiple times higher at $311 million/ton. Commenters also argued that EPA could reasonably interpret Section 112(d) to avoid this result.

Response: As EPA explained in the proposal preamble, as mandated by the LEAN court decision and CAA sections 112(d)(2), 112(d)(3), and 112(h), we proposed a MACT floor standard (which is the least stringent standard allowed by section 112 of the Clean Air Act) that would require facilities to: (1) have full or partial enclosures for the beaching process or use CO2 to suppress fumes; and (2) minimize the height, slope, and speed of beaching. We expect this will result in a small amount of unquantified emission reductions since baseline emissions are already low (less than 1 tpy of HAP) and because most facilities are already following some or all of these work practices. Regarding costs, when EPA determines the MACT floor level of control, per the section 112 of the CAA, the EPA is obligated to determine the MACT floor level regardless of costs. It is only the potential beyond-the-floor standards for which costs become an important consideration. Nevertheless, as we mentioned in the proposal preamble, the estimated costs are only $55,000 per year for the entire category and an average annual cost of $6,800 per facility. More information regarding the standards for unregulated UFIP sources is available in the following document: Unmeasurable Fugitive and Intermittent Particulate Emissions and Cost Impacts for Integrated Iron and Steel Facilities under 40 CFR part 63, subpart FFFFF, which is available in the docket for this action.

After considering public comments and available information, pursuant to CAA sections 112(d)(2) and (3) and 112(h) and the LEAN court decision, we are promulgating the same MACT Floor standard as proposed.

3. What are the final MACT standards and how will compliance be demonstrated?

a. BF Unplanned Bleeder Valve Openings

In certain instances, as provided in CAA section 112(h), if it is the judgment of the Administrator that it is not feasible to prescribe or enforce an emission standard under CAA section 112(d)(2) and (3), the EPA may set work practice standards under CAA section 112(h) in lieu of numerical emission standards. For BF unplanned bleeder valve openings, the Administrator has determined that since there is no direct measurement of emissions, we are finalizing a work practice standard. We are finalizing an operational limit for two subcategories of blast furnaces: large furnaces with a working volume of equal to or greater than 2,500 m3 ; and small furnaces with a working volume of less than 2,500 m3 . This is to account for variability in unplanned opening occurrences between furnace size due to design elements that allow higher operating pressure near the valve openings, which leads to less openings per year for large furnaces. For the large blast furnaces, we are finalizing an operational limit of four unplanned openings per rolling year per furnace. For small blast furnaces, we are finalizing an operational limit of 15 unplanned openings per rolling year per furnace. Both are based on a qualitative approach of using the highest number of unplanned openings from the top five performing furnaces (top four for large furnaces as there are only four operating large furnaces). For most MACT floor standards in NESHAP rules, we typically have actual emissions test data for each of the top five sources. To calculate the MACT floor limit we use all the data (all the runs) from all 5 sources to calculate the 99th UPL to account for variability. And, we conclude that this 99th value (which is higher than the true average) represents the average performance of the top 5 sources with an adjustment to account for variability.

With unplanned openings, we do not have a UPL type tool. So, as an alternative to a UPL, we considered all the data from the top five performers, and to ensure we account for variability among those top five performers, in this particular situation, we conclude that using the highest value (i.e., highest number of unplanned openings) from any one source within the top five reflects our best estimate of an appropriate limit that would reflect performance of the top five sources with an adjustment to ensure we adequately account for the variability among those top five sources.

This approach is appropriate because it accounts for variability among the top five blast furnaces. For new sources, we are finalizing our proposed operational limit of zero unplanned openings per rolling year for both large and small furnaces because the best performing single source large and small blast furnace in our database reported zero unplanned openings for the most recent typical year.

Additionally, we are finalizing the work practice standards proposed for both furnace subcategories that require facilities to do the following: (1) install and operate devices (e.g., stockline monitors) to continuously measure/monitor material levels in the furnace, at a minimum of three locations, using alarms to inform operators of static conditions that indicate a slip may occur, and alert them that there is a need to take action to prevent the slips and unplanned openings from occurring; (2) install and operate instruments such as a thermocouple and transducer on the furnace to monitor temperature and pressure to help determine when a slip may occur; (3) install a screen to remove fine particulates from raw materials to ensure only properly-sized raw materials are charged into the BF; and (4) develop, and submit to the EPA for approval, a plan that explains how the facility will implement these requirements. Additionally, facilities shall report the unplanned openings (including the date, time, duration, and any corrective actions taken) in their semiannual compliance reports.

b. BF Planned Bleeder Valve Openings

We are finalizing what we proposed for planned bleeder valve openings: a MACT floor limit of 8 percent opacity based on 6-minute averages. For new sources, we are finalizing an opacity of 0 percent. Facilities will have the flexibility to choose an appropriate approach to meet these opacity limits.

c. BF and BOPF Slag Processing, Handling, and Storage

As discussed above, we are finalizing an opacity limit of 10 percent based on 6-minute averages for BF and BOPF slag processing, handling, and storage, and slag pits. Regarding new sources, we are finalizing an opacity limit of 3 percent based on 6-minute averages for visible emissions from slag pits, and during slag handling, storage, and processing.

d. BF Bell Leaks

For bell leaks, we are finalizing a 20 percent opacity action level for large bell leaks as described below for new and existing large bells. This is not a numerical MACT emissions standard; because the Administrator has determined that it is not feasible to prescribe or enforce an emission standard in this instance, pursuant to CAA section 112(h), the EPA is setting work practice standards in lieu of numerical emission standards. We are also finalizing that the BF top must be observed monthly for visible emissions (VE) with EPA Method 22, 40 CFR part 60, appendix A-7, which determines the presence or absence of a visible plume, to identify leaks from the interbell relief valve (indicating leaks from the large bell). If VE are detected out of the interbell relief valve (indicating leaks from the large bell), the facility must perform EPA Method 9, 40 CFR part 60, appendix A-4, tests which determines the opacity (i.e., degree to which a plume obscures the background) monthly, and if opacity is greater than 20 percent based on an average of three instantaneous and consecutive interbell relief valve openings, the facility must initiate operational or other corrective actions within five business days. After those five business days, the facility must perform EPA Method 9 tests again and, if opacity is greater than 20 percent, the facility will have another five business days to initiate further operational or corrective actions to reduce opacity to 20 percent or lower. After five additional business days (10 business days in total), the facility must perform EPA Method 9 tests again and, if opacity is still greater than 20 percent, the large bell seals must be repaired or replaced within four months. For the new and existing small bells, we are finalizing what we proposed, a requirement that facilities shall replace or repair seals prior to a metal throughput limit, specified by the facility, that has been proven and documented to produce no opacity from the small bells. Additionally, the facility must conduct monthly visible emissions testing for 15 minutes and amend the metal throughput limit in their operation and maintenance (O&M) plan as needed.

e. Beaching of Iron From BFs

As provided in CAA section 112(h), it is the judgment of the Administrator that it is not feasible to prescribe or enforce an emission standard for emissions from the beaching process, therefore the EPA is finalizing the proposed work practice standards in lieu of numerical emission standards. This work practice standard requires facilities to: (1) have full or partial enclosures for the beaching process or use CO2 to suppress fumes; and (2) minimize the height, slope, and speed of beaching. This standard applies to both existing and new sources.

B. Reconsideration of BF Casthouse and BOPF Shop Standards for Currently Regulated Fugitive Sources Under CAA Section 112(d)(6) Technology Review

1. What did we propose for the BF casthouse and BOPF shop?

a. BF Casthouse

We proposed a 5 percent opacity limit based on 6-minute averages as an update to the CAA section 112(d)(6) technology review and proposed that facilities will need to measure opacity during the tapping operations (at least two times per month). We did not propose specific work practices for the BF casthouse, except that we proposed that the facilities will need to keep all openings, except roof monitors, closed during tapping and material transfer events (the only openings allowed during these events are those that were present in the original design of the casthouse).

b. BOPF Shop

Based on our review and analyses of the CAA section 114 information request responses we received in 2022 and 2023, and further review of the data the EPA assembled to support the 2020 RTR, we proposed that a standard composed of a 5 percent opacity limit with several specific work practices would be feasible and cost-effective for the BOPF shop. For example, based on the data we received, in the proposal we found that the maximum 3-minute opacity readings for the BOPF shops at four facilities were less than 5 percent. Furthermore, the use of work practices (described below) by the best performing facilities in the industry led us to conclude for the proposal that these work practices were feasible and, accordingly, we proposed a 5 percent opacity limit based on 3-minute average and work practices.

Specifically, we proposed that facilities will need to do the following: (1) keep all openings, except roof monitors (vents) and other openings that are part of the designed ventilation of the facility, closed during tapping and material transfer events (the only openings that would be allowed during these events are the roof vents and other openings or vents that are part of the designed ventilation of the facility) to allow for more representative opacity observations from a single opening; (2) have operators conduct regular inspections of BOPF shop structure for unintended openings and leaks; (3) optimize positioning of hot metal ladles with respect to hood face and furnace mouth; (4) monitor opacity twice per month from all openings, or from the one opening known to have the highest opacity, for a full steel cycle, which must include a tapping event; and (5) develop and operate according to an Operating Plan to minimize fugitives and detect openings and leaks. We proposed that the BOPF Shop Operating Plan shall include:

- An explanation regarding how the facility will address and implement the four specific work practices listed above;

- A maximum hot iron pour/charge rate (pounds/second) for the first 20 seconds of hot metal charge (i.e., the process of adding hot iron from the BF into the basic oxygen process furnace);

- A description of operational conditions of the furnace and secondary emission capture system that must be met prior to hot metal charge, including:

- A minimum flowrate of the secondary emission capture system during hot metal charge;

- A minimum number of times, but at least once, the furnace should be rocked between scrap charge and hot metal charge;

- A maximum furnace tilt angle during hot metal charging: and;

- An outline of procedures to attempt to reduce slopping.

2. What comments did we receive on the proposed revised BF casthouse and BOPF shop standards, and what are our responses?

a. BF Casthouse

Comment: Commenters noted that the EPA did not apply UPL calculations to the opacity data, even though the EPA's practice has been to do so for other numerical standards established on limited data sets. Commenters claim that the EPA's proposed opacity limit of 5 percent, without any adjustment for variability, lacked justification or explanation and is therefore arbitrary and capricious. These commenters argued that, when utilizing limited datasets, it is appropriate for the EPA to account for variability, and there is no technical basis for suggesting that some statistical methods should not be applied to this data set. When the EPA set the 20 percent opacity limits in 2003, the preamble included the EPA's statistical basis supporting that the limits were achievable. Commenters also stated the EPA should also include a one-time alternative limit per furnace cycle similar to the new source standards in the 2003 NESHAP.

Response: The EPA disagrees with the specific approach of using UPL calculations to develop opacity limits in the same manner that the UPL is used to calculate emissions limits. The EPA has historically used the UPL approach to develop MACT limits for stack emissions of individual pollutants but has not historically determined opacity limits using a UPL approach. The UPL calculation introduces a predictive element to the statistics in order to account for variability. However, as noted by the commenter, unlike typical emissions testing, EPA Method 9 may result in values of zero, which cannot be used in the UPL calculation. While the EPA has used the UPL approach for floor determinations when setting MACT emissions limits, the proposed changes to the BOPF Shop and BF casthouse opacity standards were based on a proposed updating of the CAA section 112(d)(6) technology review. Additionally, in the case of opacity measured according to EPA Method 9, the data EPA reviewed to develop the proposed standards were the maximum 6-minute (or 3-minute as applicable) averages evaluated over the entire test period. Likewise, compliance determinations are also based on the same approach. Utilizing the maximum short-term average during each test period to determine an appropriate standard, and to determine compliance, inherently accounts for some variation in the data used to set the standard.

However, with regard to the comments on variability, we acknowledge that there are many opacity readings that occurred over the past 2 to 6 years at the Integrated Iron and Steel (II&S) manufacturing facilities that show that there is a substantial amount of variability in opacity measurements across time and across furnaces. For example, many opacity tests for BOPF and BF furnace cycles that were completed over these 2-6 years reported maximum 3-minute and 6-minute opacity readings below 5 percent for a substantial amount of the cycles. In fact, for many furnace cycles the maximum opacity was 0 percent. On the other hand, the data show that during some BOPF or BF cycles, opacity is above 5 percent and sometimes well above 20 percent. The EPA has additionally continued to receive opacity data and analyses since the close of the public comment period on this rulemaking.

The EPA was not able to adequately analyze all the available data before the deadline for this final rule ordered by the court in California Communities Against Toxics. Also, for most of the opacity tests that had maximum opacity readings above 5 and 10 percent, the EPA does not have any information that explains why the opacity readings were higher than 5 percent on those particular days. In most cases, the EPA is unable to determine the cause of the higher values based on the data and information currently available. Until further revision, the opacity limits in the NESHAP for existing BOPF Shops and existing BF casthouses will remain at 20 percent based on 3-minute averages for the BOPF Shop and 6-minute averages for the BF casthouse.

The opacity data and further explanation of the opacity data and related information can be found in the technical memo titled: Unmeasured Fugitive and Intermittent Particulate Emissions and Cost Impacts for Integrated Iron and Steel Facilities under 40 CFR part 63, subpart FFFFF, which is in docket for this final rule.

b. BOPF Shop

Comment: Some commenters conducted their own assessment of what measures would be needed to comply with the proposed opacity limit and work practice standards, which is of course facility-specific, because every BOPF shop is unique. Based on their assessments, these commenters asserted that each BOPF shop—after applying all “required” work practice standards and even other work practices that the EPA suggested—would likely need to install full-shop controls to meet a 5 percent opacity limit at all times. The commenters represented that the cost to apply this type of control would be high and would involve the addition of at least one large fabric filter device to properly capture fugitive emissions and allow for proper ventilation for the building. The commenters asked EPA to take into account the significant changes BOPF shops would have to make to meet a 5 percent opacity standard that even the best performers cannot currently achieve on a regular basis. They suggested that because of the exorbitantly and unreasonably expensive measures that would need to be undertaken by this industry sector, and the significant possibility that even facilities installing such measures would not be able to consistently meet the 5 percent opacity standard, the EPA should not move forward with the proposed opacity limit, at least until the Agency undertakes a robust engineering analysis to determine the technical and economic feasibility of controls that would be needed for BOPF shops to meet this lower standard.

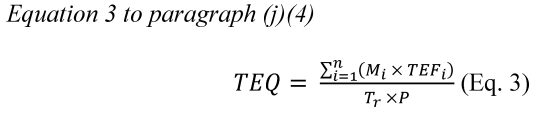

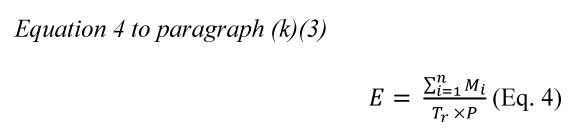

Response: After considering public comments, the EPA now recognizes some operations may need to make more significant changes than we anticipated at proposal to meet the 5 percent opacity standard at all times. We acknowledge that there are many opacity readings that occurred over the past 2 to 6 years that indicate that there is a substantial amount of variability across time and across furnaces. For example, many opacity tests for BOPF cycles (i.e., steel cycles) that were completed over these 2-6 years reported maximum 3-minute opacity readings below 5 percent for a substantial amount of the cycles. On the other hand, the data show that during some BOPF cycles, opacity is above 5 percent and sometimes above 20 percent.